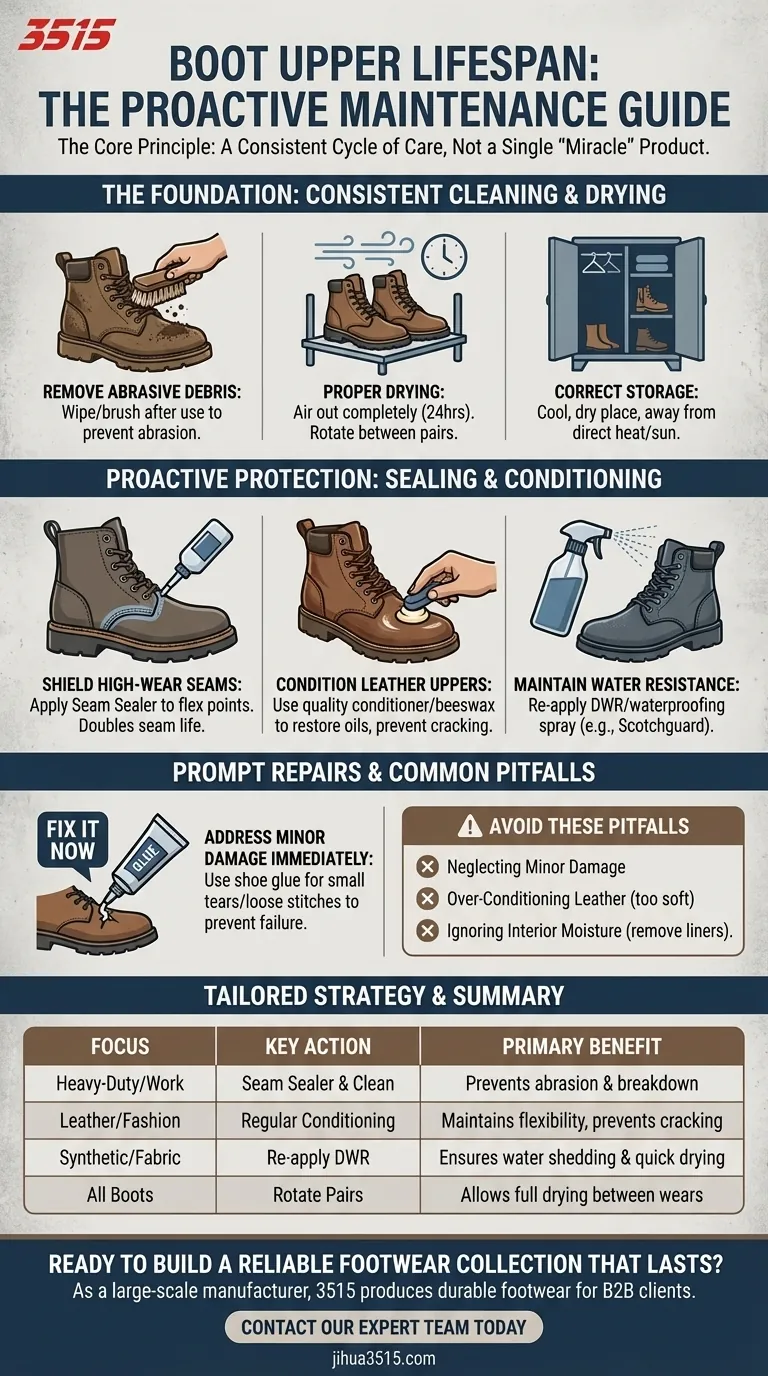

To significantly extend the lifespan of your boot uppers, you must adopt a proactive maintenance routine focused on three key areas: consistent cleaning, preemptive protection of high-wear areas, and prompt minor repairs. This involves regularly removing abrasive debris, conditioning leather to prevent cracking, and applying specialized treatments like seam sealers and waterproofing sprays to shield the materials from environmental damage.

The core principle of boot longevity is not a single "miracle" product, but a consistent cycle of care. By treating your boots as an investment and addressing small issues before they escalate, you prevent the gradual breakdown that leads to premature failure.

The Foundation: Consistent Cleaning and Drying

The simplest habits often have the most significant impact. Grit and moisture are the primary enemies of all boot materials, and managing them is your first line of defense.

Removing Abrasive Debris

Everyday dirt, sand, and mud act like fine-grit sandpaper. As you walk, these particles grind against the boot's fibers and stitching, causing gradual but significant abrasion that eventually leads to tears and seam failure.

Wipe down or brush off your boots after use, especially if they are heavily soiled. This simple act removes the abrasive elements before they can do lasting damage.

The Importance of Proper Drying

Moisture is detrimental to nearly all footwear materials, weakening leather, degrading synthetic fabrics, and compromising the adhesives that hold the boot together.

Allow boots to dry completely before storing or wearing them again. For footwear that sees heavy daily use, rotating between two pairs allows each one the necessary 24 hours to fully air out and release absorbed moisture.

Correct Storage Conditions

Where you keep your boots matters. Storing them in a cool, dry place away from direct heat sources or sunlight prevents materials from becoming brittle or warped.

Proactive Protection: Sealing and Conditioning

Once your boots are clean and dry, the next step is to apply protective barriers that shield them from wear and tear.

Shielding High-Wear Seams

The seams, particularly around the flex points of the forefoot, are a boot's structural weak point. They are highly susceptible to abrasion from rocks, roots, and friction.

Applying a seam sealer to these high-wear areas creates a durable, flexible coating that protects the stitching. This single act can potentially double the lifespan of your boot's seams.

Conditioning Leather Uppers

Leather is a skin and requires moisture to remain flexible and strong. Without it, leather will dry out, become brittle, and eventually crack, especially at flex points.

Use a quality leather conditioner or a treatment like beeswax spray to restore essential oils. This maintains the material's elasticity and structural integrity.

Maintaining Water Resistance

For synthetic or fabric boots, the factory-applied Durable Water Repellent (DWR) coating wears off over time. This causes the fabric to "wet out," becoming saturated, heavy, and slow to dry.

Regularly apply a waterproofing treatment like Scotchguard. This helps the uppers shed water, maintaining their performance and speeding up drying time.

Common Pitfalls to Avoid

Effective maintenance is about balance. Avoiding common mistakes is just as important as performing the right tasks.

Neglecting Minor Damage

A small tear, a peeling sole edge, or a loose stitch can seem insignificant. However, these minor issues quickly worsen under stress, leading to catastrophic and often unrepairable failures.

Address damage immediately with products like shoe glue or moldable waterproof glue. A five-minute repair today can prevent you from having to replace the entire boot next month.

Over-Conditioning Leather

While conditioning is crucial, too much of a good thing can be a problem. Over-saturating leather with oils or waxes can make it too soft, causing it to lose the structural support your foot needs.

Follow the product instructions and apply conditioner only when the leather appears dry.

Focusing Only on the Outside

The interior environment of your boot is also harsh. Sweat and internal moisture can break down materials from the inside out.

If your boots have removable liners or insoles, take them out to dry separately. This ensures the entire boot system dries thoroughly.

A Maintenance Strategy for Your Boots

Your specific routine should match your boot type and how you use it. Tailor your approach for the best results.

- If your primary focus is heavy-duty hiking or work boots: Prioritize applying seam sealer to high-wear areas and cleaning them regularly to remove abrasive grit.

- If your primary focus is leather fashion or winter boots: Concentrate on regular conditioning to prevent cracking and maintain the material's supple appearance.

- If your primary focus is synthetic fabric boots: Re-apply a DWR waterproofing treatment periodically to maintain water resistance and breathability.

- For any boot that sees frequent use: Implement a rotation system with a second pair to guarantee each one can dry completely between wears.

A proactive maintenance routine transforms your boots from a disposable item into a long-term, reliable tool.

Summary Table:

| Maintenance Focus | Key Action | Primary Benefit |

|---|---|---|

| Cleaning & Drying | Remove debris & allow full drying | Prevents abrasion & material breakdown |

| Seam Protection | Apply seam sealer to high-wear areas | Doubles the lifespan of critical seams |

| Leather Care | Condition with oils/wax to prevent cracking | Maintains flexibility and structural integrity |

| Water Resistance | Re-apply DWR/waterproofing spray | Ensures boots shed water and dry quickly |

Ready to build a reliable footwear collection that lasts?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots, hiking boots, and fashion boots designed to withstand rigorous use. We can help you source or create boots built for longevity from the start.

Contact our expert team today to discuss your specific needs and discover how our manufacturing expertise can provide your customers with superior, long-lasting footwear.

Visual Guide

Related Products

- Wholesale Classic Leather Lace-Up Ankle Boots for Brand Manufacturing

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What is the appeal of two-tone leather lace wingtip dress shoes? Bold Style & Timeless Elegance

- What type of boots look best with dresses? Achieve a Flawless, Proportional Look

- What benefits do dress boots provide? Style, Support & Versatility for Any Occasion

- What are the key tips for wearing lace-up boots properly? Achieve Perfect Fit & Comfort

- What factors should be considered when buying new lace-up boots? Find Your Perfect Fit & Purpose