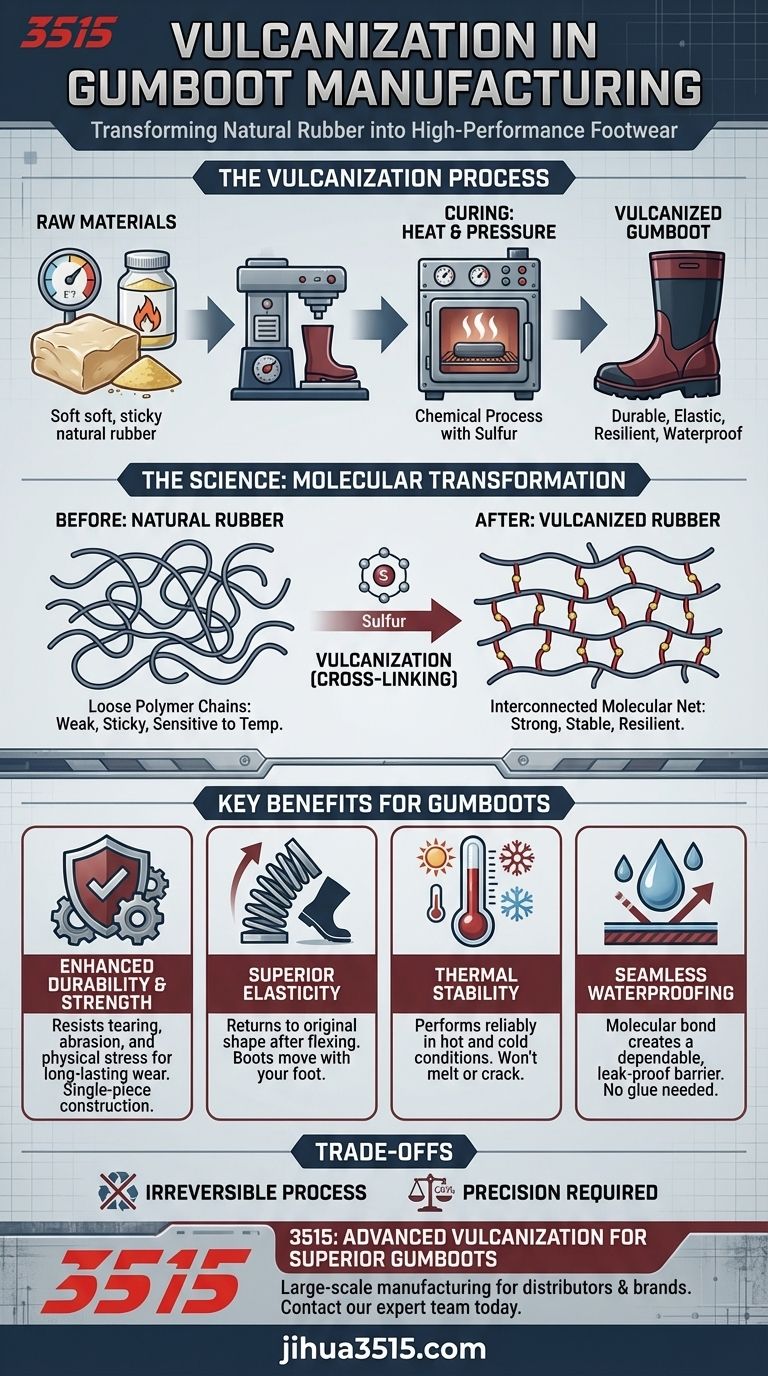

Vulcanization is a chemical process that transforms soft, sticky natural rubber into the durable, elastic, and resilient material essential for high-quality gumboots. By heating the rubber with sulfur under pressure, a molecular change occurs that permanently locks in the properties required for tough, flexible, and waterproof footwear.

The core purpose of vulcanization is to fundamentally alter the nature of rubber. It converts a weak raw material into a stable, high-performance product by creating a strong, interconnected molecular structure, making modern, reliable gumboots possible.

From Raw Material to Resilient Footwear

To understand why vulcanization is so critical, you must first understand the limitations of the raw material it transforms.

The Problem with Natural Rubber

In its natural state, rubber (or latex) is not a practical material for manufacturing. It is sticky, deforms easily, and reacts poorly to temperature changes—becoming soft and gooey when hot, and brittle when cold.

The Vulcanization Solution

The process, developed by Charles Goodyear, solves these problems. The raw rubber compound is mixed with a curing agent, primarily sulfur, molded into the final boot shape, and then subjected to intense heat and pressure in a process known as curing.

The Science Behind the Strength: Cross-Linking

At a molecular level, rubber is made of long, separate polymer chains. During vulcanization, the sulfur atoms form strong cross-links, or bridges, between these individual chains. This transforms the loose collection of strands into a single, unified, and robust molecular net.

Key Benefits of Vulcanization in Gumboots

This molecular transformation imparts several crucial properties that define a quality gumboot.

Enhanced Durability and Strength

The cross-linked structure prevents the polymer chains from moving independently, making the material far more resistant to tearing, abrasion, and physical stress. This is what makes a gumboot tough.

Superior Elasticity

Vulcanization gives rubber its characteristic "memory." The material can be stretched and flexed repeatedly but will return to its original shape. This ensures the boot moves with your foot without becoming permanently deformed.

Thermal Stability

A vulcanized boot maintains its integrity and flexibility across a wide range of temperatures. It won't melt on a hot pavement or crack in the cold, providing reliable performance in any weather.

Seamless Waterproofing

The process allows different parts of the boot—such as the sole and the upper—to be fused together into a single, monolithic piece. This molecular bond creates a seamless, waterproof barrier, largely replacing glues or cements that can degrade and create leak points over time.

Understanding the Trade-offs

While vulcanization is overwhelmingly beneficial for rubber products, it's important to recognize its nature and limitations.

An Irreversible Process

Vulcanization is a permanent chemical change. Once a boot is cured, the rubber cannot be melted down and easily reshaped, which presents challenges for recycling.

A Matter of Precision

The process requires exact control over temperature, time, and the chemical formula. Too little sulfur or heat results in a weak, under-cured product, while too much can make the rubber hard and brittle, losing its essential flexibility.

How This Applies to Your Footwear

Understanding this core manufacturing process allows you to make a more informed choice.

- If your primary focus is longevity and toughness: Vulcanization creates a single-piece construction that resists splitting at the seams far better than glued alternatives.

- If your primary focus is reliable waterproofing: The molecular fusion achieved through vulcanization provides the most dependable barrier against water intrusion.

- If your primary focus is all-weather performance: This process ensures your boots remain flexible and functional, whether in summer heat or winter cold.

Ultimately, vulcanization is the unseen technology that guarantees your gumboots have the structural integrity and resilience to do their job effectively.

Summary Table:

| Key Aspect | Why It Matters for Gumboots |

|---|---|

| Enhanced Durability | Resists tearing, abrasion, and physical stress for long-lasting wear. |

| Superior Elasticity | Boots flex with your foot and return to their original shape. |

| Thermal Stability | Performs reliably in both hot and cold weather conditions. |

| Seamless Waterproofing | Creates a one-piece, molecular bond that prevents leaks. |

As a large-scale manufacturer, 3515 leverages advanced vulcanization techniques to produce superior gumboots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable, waterproof footwear built to last. Ready to enhance your product line with high-performance rubber boots?

Contact our expert team today to discuss your manufacturing needs and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What are the modern uses of Wellington boots? From PPE to Fashion & Agriculture

- What are the best wellies for individuals with wide calves? Find Your Perfect, Comfortable Fit

- How did Wellington boot designs change in the late 20th century? From a single boot to two specialized paths

- What was the significance of rubber Wellington boots during WWI? A Life-Saving Innovation for Soldiers

- What are the drawbacks of natural rubber gumboots? Weighing the Pros and Cons for Your Needs

- What are the benefits of PVC boots for gardening? Waterproof & Affordable Protection

- How can you tell if Wellington boots are too small? 4 Key Fit Checks for All-Day Comfort

- What should I do if I have chosen the wrong size for my Wellington boots? Get the Perfect Fit & Avoid Future Mistakes