In essence, vulcanization is a chemical process that converts raw natural rubber into a strong, durable, and elastic material. By heating the rubber in the presence of sulfur and other curing agents, its molecular structure is fundamentally altered, transforming it from a sticky, weak substance into the stable and useful product we use in countless applications.

The core problem with raw rubber is its molecular instability; it's weak and deforms easily. Vulcanization solves this by creating a network of chemical cross-links between the rubber's polymer chains, resulting in a tough, elastic, and commercially viable material.

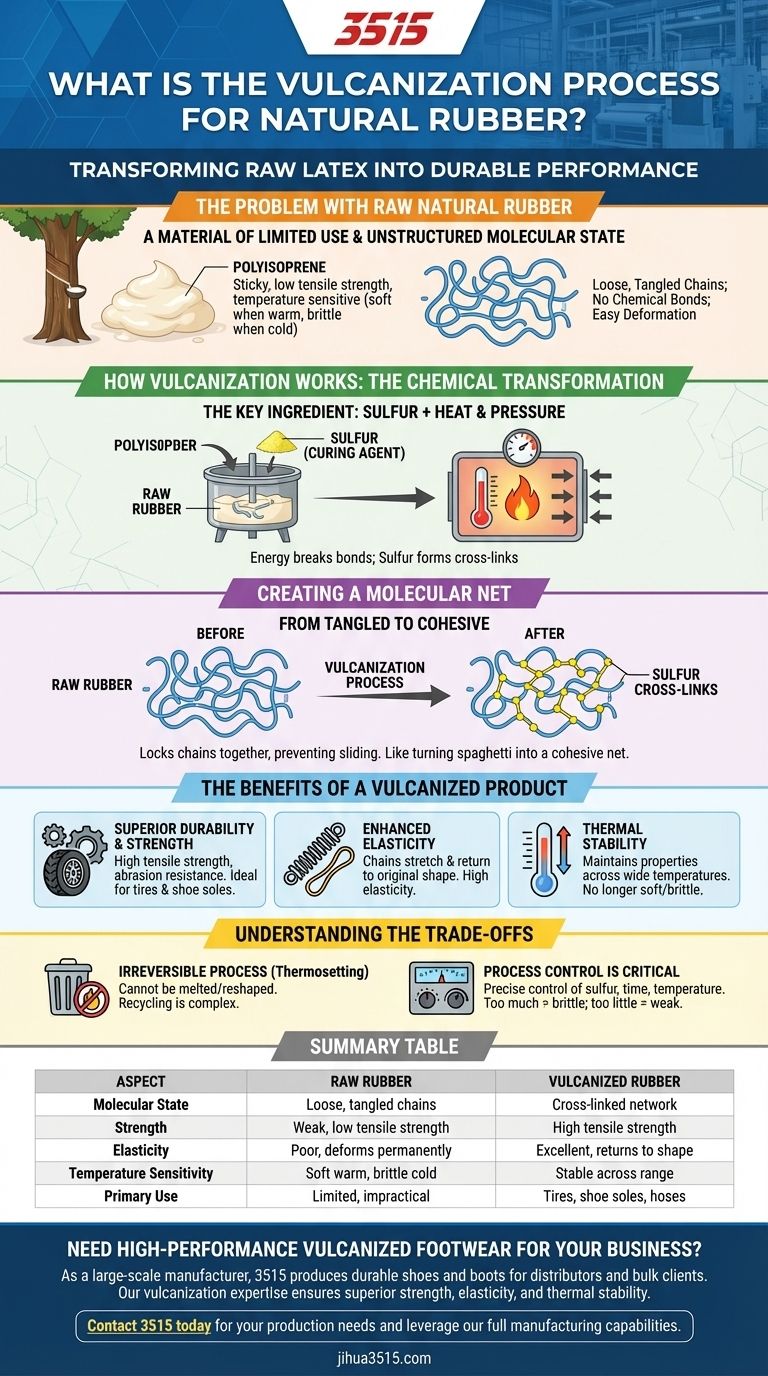

The Problem with Raw Natural Rubber

A Material of Limited Use

In its natural state, harvested as latex from rubber trees, rubber is a polymer called polyisoprene. This raw material is sticky, has low tensile strength, and is highly sensitive to temperature changes. It becomes soft and gummy when warm and brittle when cold, making it impractical for most applications.

An Unstructured Molecular State

At the molecular level, raw rubber consists of long, tangled polymer chains. These chains are not chemically bonded to each other, allowing them to slide past one another easily when stress is applied. This is why the material deforms permanently and has very poor elasticity.

How Vulcanization Works: The Chemical Transformation

The Key Ingredient: Sulfur

Developed by Charles Goodyear in the 19th century, the process hinges on one key ingredient: sulfur. When raw rubber is mixed with sulfur and other activators or accelerators, the stage is set for a permanent chemical change.

The Role of Heat and Pressure

The mixture of rubber and sulfur is then heated under pressure. The heat provides the necessary energy to break the chemical bonds within both the sulfur molecules and the rubber polymer chains, allowing them to react with each other.

Creating a Molecular Net

During this heating process, sulfur atoms form strong chemical bridges, or cross-links, between the individual polymer chains. This locks the chains together, preventing them from sliding apart.

You can think of it like turning a plate of tangled spaghetti (raw rubber) into a cohesive net. The individual strands are now interconnected, creating a single, robust structure.

The Benefits of a Vulcanized Product

Superior Durability and Strength

The network of cross-links dramatically increases the rubber's tensile strength and resistance to abrasion. This newfound toughness is what allows it to withstand the demanding conditions required for tires and shoe soles.

Enhanced Elasticity

Because the polymer chains are now tethered together, the rubber can be stretched, but the cross-links will pull the chains back to their original position once the force is removed. This property, known as high elasticity, is a defining characteristic of vulcanized rubber.

Thermal Stability

Vulcanization makes rubber far less sensitive to temperature. It maintains its strength and flexibility across a wide temperature range, no longer turning soft in the heat or brittle in the cold. This stability is critical for products that must perform in varying environments.

Understanding the Trade-offs

The Process is Irreversible

Vulcanization is a thermosetting process. Once the rubber is cured and the cross-links are formed, it cannot be melted down and reshaped. This makes recycling vulcanized rubber more complex than recycling thermoplastic materials.

Process Control is Critical

The final properties of the rubber are determined by the degree of vulcanization. The amount of sulfur, heating time, and temperature must be precisely controlled. Too much cross-linking can make the rubber hard and brittle, while too little will leave it soft and weak.

Applying This to Key Goals

The vulcanization process is what makes rubber a cornerstone of modern industry. How you view its importance depends on your objective.

- If your primary focus is high-performance durability: Vulcanization provides the immense strength, abrasion resistance, and thermal stability required for demanding applications like vehicle tires and industrial hoses.

- If your primary focus is consumer product manufacturing: The process allows rubber to be permanently molded into consistent shapes while imparting the toughness and flexibility needed for products like footwear.

- If your primary focus is material science: Understand that vulcanization is the fundamental curing process that transforms a polymer's properties from weak and unstable to strong and elastic by creating a cross-linked molecular network.

Ultimately, vulcanization is the critical step that unlocks the true potential of rubber, converting a raw natural substance into one of engineering's most versatile materials.

Summary Table:

| Aspect | Raw Rubber | Vulcanized Rubber |

|---|---|---|

| Molecular State | Loose, tangled chains | Cross-linked network |

| Strength | Weak, low tensile strength | High tensile strength |

| Elasticity | Poor, deforms permanently | Excellent, returns to shape |

| Temperature Sensitivity | Soft when warm, brittle when cold | Stable across a wide range |

| Primary Use | Limited, impractical | Tires, shoe soles, hoses |

Need High-Performance Vulcanized Footwear for Your Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable shoes and boots for distributors, brand owners, and bulk clients. Our expertise in the vulcanization process ensures superior product strength, elasticity, and thermal stability—exactly what your customers demand.

Contact 3515 today to discuss your production needs and leverage our full manufacturing capabilities for all types of shoes and boots.

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

People Also Ask

- What are the core advantages of high-precision 3D printing in diabetic foot insoles? Revolutionizing Smart Monitoring

- Why are physical proxy objects like vinyl or carpet necessary in AR? Essential Factors for Tactile Perception Study

- What are the functions of disposable nose clips and mouthpieces with filters? Key Tools for Footwear Respiratory Tests

- How does heel height affect comfort in boots? The Key to All-Day Wearability

- Why is the cleaning process using high-purity distilled water necessary for footwear sole polymer analysis?

- What is the difference between waterproof and water-resistant boots? Choose the Right Footwear for Any Condition

- What is the purpose of collecting bilateral plantar pressure data? Master Footwear Biomechanics and Symmetry

- How does core temperature affect toe warmth while cycling? Master Your Body's Heating System