At the core of every safety shoe is a component that is never seen by the end-user but dictates its every feature: the shoe last. A shoe last is the solid, foot-shaped form used by manufacturers to give a shoe its fundamental shape, size, and internal volume. In safety shoe manufacturing, its role is elevated because it serves as the critical foundation for correctly positioning and integrating protective components like the steel or composite toe cap.

The shoe last is more than just a mold; it is the architectural blueprint that ensures a safety shoe is not only protective but also ergonomic and comfortable. Its design directly dictates the fit of the safety toe, the support of the arch, and the shoe's ability to prevent fatigue over a long workday.

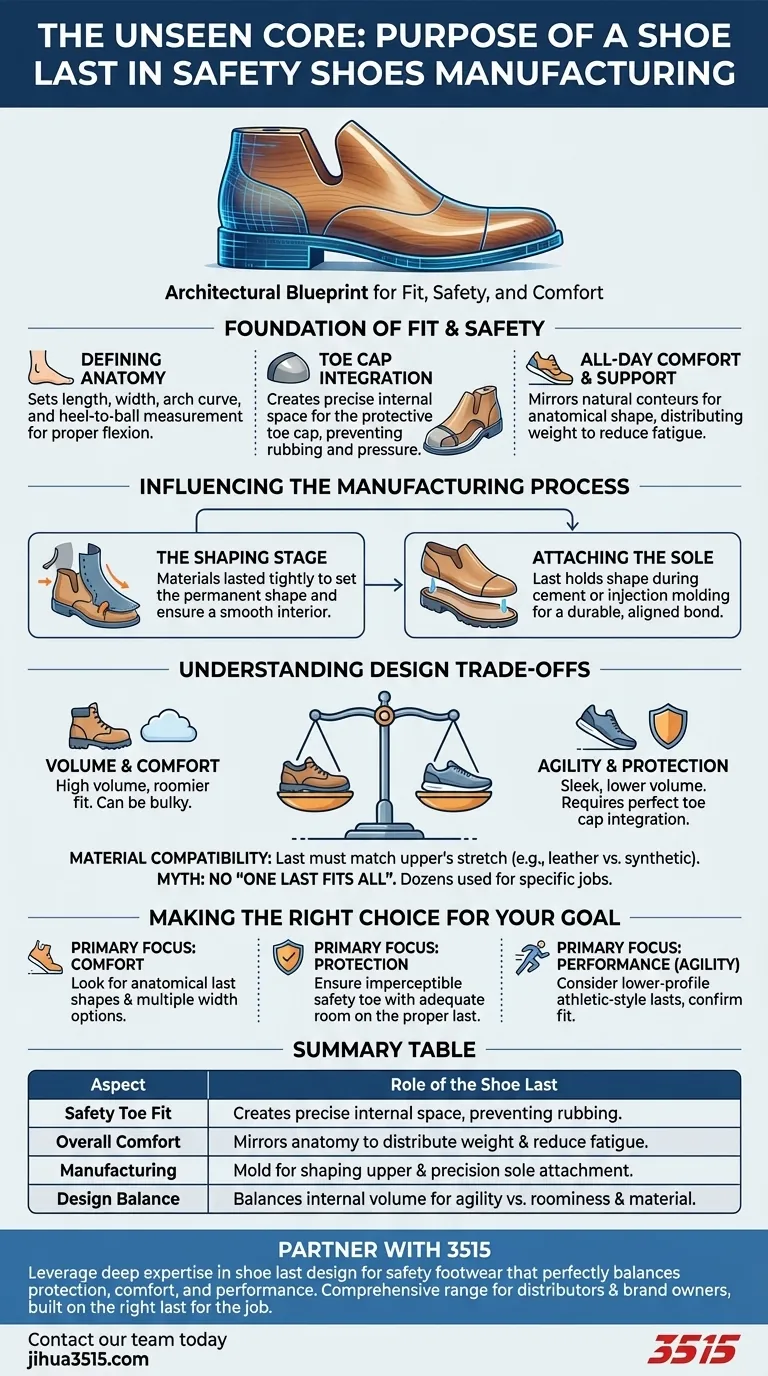

The Last as the Foundation of Fit and Safety

A shoe last is the starting point of design, and its specific dimensions have a cascading effect on the final product's performance and wearability.

Defining the Shoe's Anatomy

The last sets all critical dimensions of the footwear. This includes the overall length and width, the volume of the toe box, the curve of the arch, and the heel-to-ball measurement, which is crucial for proper foot flexion.

The Critical Role in Toe Cap Integration

In safety footwear, the last's most important function is to create the precise internal space required for the protective toe cap.

The shape of the last ensures there is adequate clearance around the toes, preventing the hard cap from rubbing, pinching, or causing pressure. A poorly designed last will result in a safety shoe that is technically compliant but practically unwearable.

Ensuring All-Day Comfort and Support

A well-designed last mirrors the natural contours of the human foot. This anatomical shape provides proper support and helps distribute weight evenly, which is essential for reducing muscle fatigue and preventing common foot ailments during long shifts.

How the Last Influences the Manufacturing Process

The last is not just a design tool; it is an active component in the physical construction of the shoe.

The Shaping Stage

During a process called "lasting," the shoe's upper materials—whether leather or synthetics—are stretched and molded tightly around the last. This step sets the upper's permanent shape and ensures a smooth, wrinkle-free interior.

Attaching the Sole

The last remains inside the upper, holding its precise shape while the outsole is attached with cement or through direct injection molding. This guarantees a durable and perfectly aligned bond between the two main parts of the shoe.

Understanding the Trade-offs: Last Design vs. Protection

The design of a last is a careful balance of competing priorities. Understanding these trade-offs is key to appreciating why different safety shoes feel so different.

The Volume vs. Agility Dilemma

A last with a high internal volume creates a roomier, more generous fit that can feel very comfortable. However, this can result in a bulkier shoe. A sleeker, lower-volume last can produce a more agile and aesthetically pleasing shoe, but it risks creating pressure points if the toe cap is not integrated perfectly.

Material Compatibility

The chosen last must be compatible with the upper materials. For example, a last designed for pliable full-grain leather, which stretches and conforms easily, may not work for a rigid, non-stretching synthetic material. The design must account for the material's properties to achieve the intended fit.

The Myth of "One Last Fits All"

There is no single, perfect last. A last for a foundry boot will have different characteristics than one for an athletic-style safety sneaker. Manufacturers use dozens of different lasts to create footwear tailored to specific job functions, environments, and foot shapes.

Making the Right Choice for Your Goal

When selecting safety footwear, understanding the unseen role of the last helps you focus on what truly matters for your needs.

- If your primary focus is all-day comfort: Look for brands that advertise their unique last shapes or offer multiple width options, as this signals a commitment to anatomical fit.

- If your primary focus is maximum protection: Ensure the shoe's safety toe feels imperceptible when you walk; a shoe built on a proper last provides adequate room so the protective cap never rubs or pinches.

- If your primary focus is a specific job performance (e.g., agility): Consider lower-profile safety shoes built on more athletic-style lasts, but always confirm a proper, non-restrictive fit in the toe box area.

Ultimately, the invisible architecture of the shoe last is the true determinant of a safety shoe's success.

Summary Table:

| Aspect | Role of the Shoe Last |

|---|---|

| Safety Toe Fit | Creates precise internal space to prevent rubbing or pinching from the protective cap. |

| Overall Comfort | Mirrors the foot's anatomy to distribute weight evenly and reduce fatigue. |

| Manufacturing | Serves as the mold for shaping the upper and attaching the sole with precision. |

| Design Balance | Balances internal volume for agility vs. roominess and material compatibility. |

Partner with 3515 for Your Safety Footwear Needs

As a large-scale manufacturer, 3515 leverages deep expertise in shoe last design to produce safety footwear that perfectly balances protection, comfort, and performance. We create a comprehensive range of shoes and boots for distributors, brand owners, and bulk clients, ensuring each pair is built on the right last for its specific job function and target market.

Let us help you develop safety footwear that workers will want to wear all day. Contact our team today to discuss your manufacturing requirements.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health