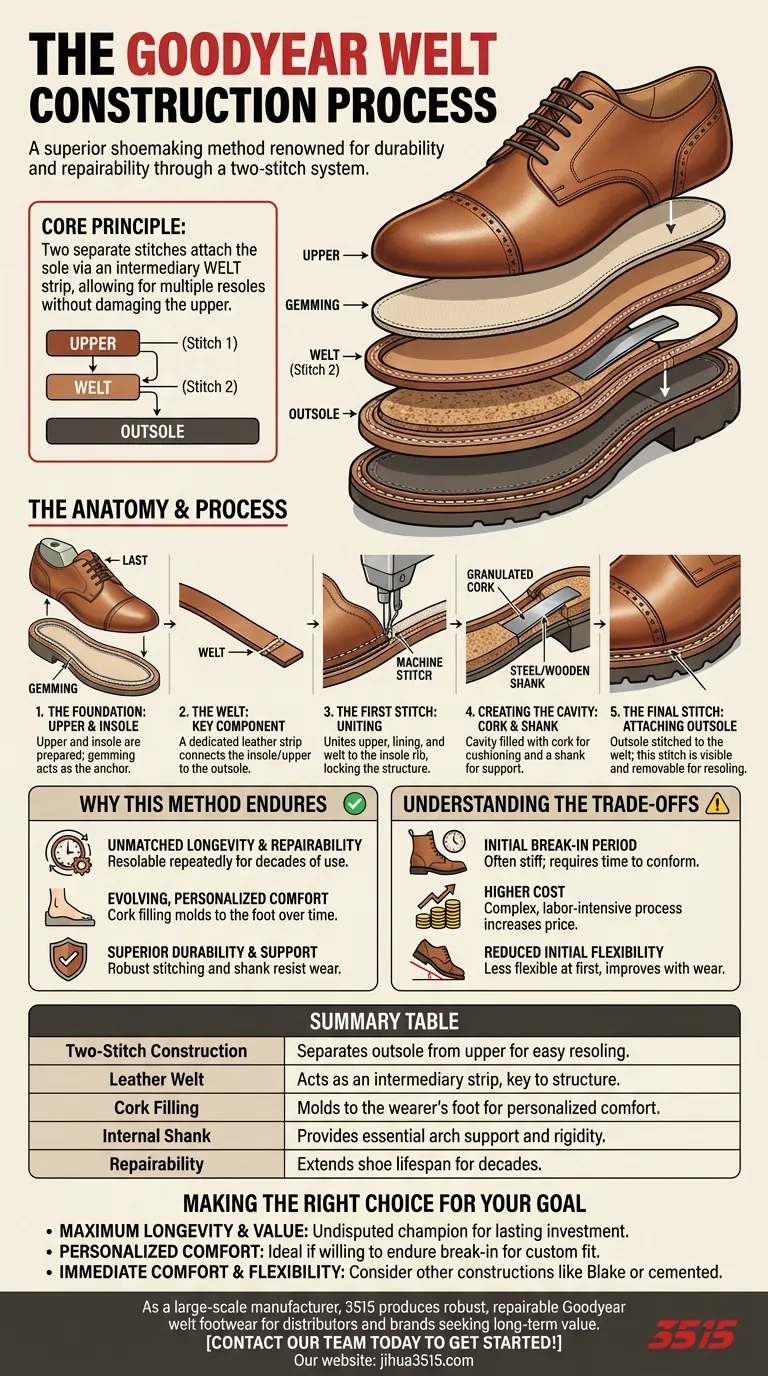

At its core, Goodyear construction is a superior method of shoemaking where two separate stitches are used to attach the sole. A strip of leather called a welt is first stitched to the upper and the insole. A second, entirely different stitch then attaches the outsole to this welt, creating a shoe renowned for its durability and repairability.

The critical insight of the Goodyear welt is that the outsole is not stitched directly to the upper. This separation allows the shoe to be resoled multiple times without compromising its core structure, granting it an exceptionally long lifespan.

The Anatomy of a Goodyear Welted Shoe

Understanding the Goodyear welt requires looking at how the shoe is assembled layer by layer. The process is a marvel of engineering, creating a robust and serviceable product.

The Foundation: Upper and Insole

The process begins by stretching the leather upper over a form called a last.

A canvas rib, known as gemming, is cemented around the perimeter of the insole. This rib acts as the crucial anchor point for the first and most important stitch.

The Key Component: The Welt

The welt is a dedicated strip of leather that runs along the outsole's edge.

Its sole purpose is to act as an intermediary, connecting the insole and upper to the outsole without creating a direct, single stitch path through all of them.

The First Stitch: Uniting Insole, Upper, and Welt

This is the defining step of the process. A specialized machine or a skilled artisan sews the upper, the lining, and the welt to the canvas rib on the insole.

This stitch locks the shoe's upper structure together firmly.

Creating the Cavity: Cork and Shank

This first stitch creates a cavity between the insole and the outsole.

This space is filled with a layer of granulated cork, which provides cushioning and will eventually mold to the shape of the wearer's foot. A wooden or steel shank is also added in this cavity to provide arch support and structural rigidity.

The Final Stitch: Attaching the Outsole

The outsole is then attached to the shoe. Critically, it is stitched only to the welt.

This second, external stitch is visible running around the edge of the shoe and is the key to the shoe's repairability. A cobbler can simply cut this stitch to remove and replace a worn-out sole.

Why This Method Endures

Invented by Charles Goodyear's son in the late 1800s, this construction method remains the gold standard for high-quality footwear for several key reasons.

Unmatched Longevity and Repairability

Because the outsole is a separate, replaceable component, Goodyear welted shoes can be resoled repeatedly. This allows a well-cared-for pair of shoes to last for decades, not just years.

Evolving, Personalized Comfort

While initially firm, the cork filling between the insole and outsole gradually compresses and conforms to the unique shape of your foot. Over time, this creates a personalized fit that is exceptionally comfortable and supportive.

Superior Durability and Support

The combination of robust stitching, the structural welt, and the internal shank creates an incredibly strong and supportive shoe. This construction offers unmatched resistance to daily wear and tear.

Understanding the Trade-offs

While considered a pinnacle of shoemaking, the Goodyear welt is not without its compromises. Understanding them is key to making an informed decision.

The Initial Break-in Period

The robust, multi-layered construction results in a shoe that is often stiff and firm out of the box. A distinct break-in period is usually required before the shoe becomes comfortable and the cork begins to mold.

Higher Cost

The process is complex and labor-intensive, sometimes involving over 150 separate steps. This skilled labor and material usage naturally result in a higher initial purchase price compared to simpler, cemented shoe constructions.

Reduced Initial Flexibility

Compared to more modern construction methods where soles are simply glued on, a Goodyear welted shoe is inherently less flexible at first. The flexibility increases as the leather and cork break in with wear.

Making the Right Choice for Your Goal

Deciding if you need a Goodyear welted shoe comes down to your priorities.

- If your primary focus is maximum longevity and long-term value: This construction is the undisputed champion, as the ability to resole the shoe makes it a lasting investment.

- If your primary focus is personalized comfort for daily wear: This method is ideal, provided you are willing to invest the time in the initial break-in period to achieve a custom-like fit.

- If your primary focus is immediate, out-of-the-box comfort and flexibility: You may prefer a shoe with a different construction, such as a Blake stitch or a cemented sole.

Ultimately, choosing a Goodyear welted shoe is an investment in a time-tested tradition of quality, durability, and enduring style.

Summary Table:

| Feature | Benefit |

|---|---|

| Two-Stitch Construction | Separates the outsole from the upper for easy resoling. |

| Leather Welt | Acts as an intermediary strip, key to the shoe's structure. |

| Cork Filling | Molds to the wearer's foot for personalized comfort over time. |

| Internal Shank | Provides essential arch support and structural rigidity. |

| Repairability | Allows the shoe to be resoled multiple times, extending its lifespan for decades. |

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear using time-tested construction methods like the Goodyear welt.

We offer robust, durable, and repairable footwear solutions perfect for distributors, brand owners, and bulk clients seeking long-term value and superior quality for their customers.

Let's discuss your specific needs and how our production capabilities can bring your next footwear project to life.

Contact our team today to get started!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- What features make dress shoes suitable for standing all day? Achieve All-Day Comfort with Anatomical Design

- What is the insole of a dress shoe and what materials is it usually made from? | A Guide to Quality & Comfort

- How should leather conditioner be applied? A Step-by-Step Guide to Perfect Results

- What types of events require black-tie dress shoes? The Ultimate Guide to Formal Footwear

- What are the recommended construction methods for quality dress shoes? Goodyear Welt vs. Blake Stitch Explained

- What makes Goodyear welted leather special? Discover the Secret to Decades-Lasting Footwear

- Why is a shoe horn recommended for putting on leather shoes? Protect Your Investment & Maintain Shape

- What is the purpose of pigmented cream polish? Restore and Nourish Your Leather in One Step