The primary ASTM standard for safety footwear is ASTM F2413-18. This standard establishes the minimum requirements for the performance, fit, and function of protective footwear designed to guard against a variety of workplace hazards, including impact, compression, and electrical shock.

While ASTM F2413 defines what level of protection a safety shoe must provide, it works in tandem with ASTM F2412, which specifies how to test for that protection. Critically, neither of these foundational standards includes a requirement for slip resistance.

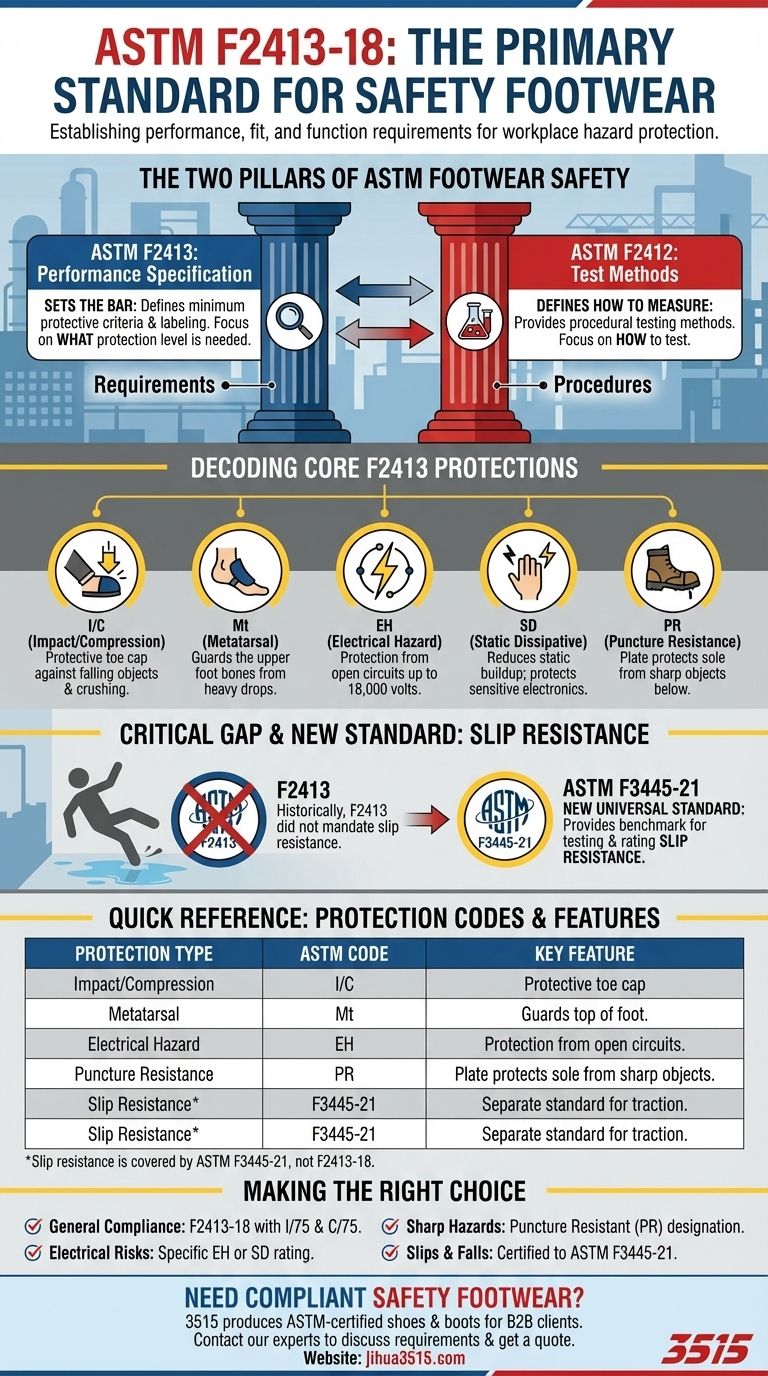

The Two Pillars of ASTM Footwear Safety

To fully grasp footwear compliance, you must understand the two core documents that form the foundation of the ASTM standards. They are separate but completely interdependent.

ASTM F2413: The Performance Specification

This is the standard most people refer to when discussing safety footwear. It outlines the specific performance requirements a shoe must meet to be considered "safety" or "protective" footwear.

It defines the minimum criteria for protection against a range of specific hazards and also dictates the labeling system used to identify which protections a particular shoe offers.

ASTM F2412: The Test Methods

This standard is the procedural counterpart to F2413. It provides the detailed laboratory methods that must be used to test and measure a shoe's resistance to the various hazards.

In simple terms, F2413 sets the bar, and F2412 defines how to measure if the footwear has cleared that bar. A shoe cannot be certified to F2413 without being tested according to the methods in F2412.

Decoding the Core Protections of F2413

ASTM F2413 outlines several key protective features. Each certified feature is noted on the shoe's official label, allowing you to match footwear capabilities to your specific workplace risks.

Impact (I) and Compression (C) Resistance

This is the most fundamental feature, referring to the protective toe cap. It guards the toes against injury from falling objects (impact) and crushing forces (compression).

Metatarsal (Mt) Protection

This protection extends beyond the toes to cover the upper part of the foot (the metatarsal bones). It is crucial in environments where objects could drop or roll onto the top of the foot.

Electrical Hazard (EH) and Static Dissipative (SD)

These are two distinct electrical protections. EH-rated footwear is designed to protect the wearer from open electrical circuits of up to 18,000 volts.

SD footwear is engineered to reduce the buildup of static electricity, which is critical for protecting sensitive electronic equipment or preventing ignition in flammable environments.

Puncture Resistance (PR)

This indicates the presence of a puncture-resistant plate in the sole of the shoe, designed to protect the foot from sharp objects like nails, glass, or metal shards from below.

Common Pitfalls to Avoid

Understanding the standards also means understanding their limitations. The most common mistake is assuming that a single standard covers all possible workplace foot hazards.

The Critical Gap: Slip Resistance

Historically, ASTM F2413 did not mandate a specific level of slip resistance. This was a significant gap, as slips, trips, and falls are among the most common workplace injuries.

To address this, a new, separate standard was introduced: ASTM F3445-21. This standard provides a universal specification for testing and rating slip resistance, giving safety managers a reliable benchmark for the first time.

A Note on International Standards

While ASTM is the key standard in the United States, the prevalent standard in Europe is EN ISO 20345. While the testing methods differ, it covers a similar range of protective features using a system of codes like SB, S1, S2, and S3 to denote specific capabilities.

Making the Right Choice for Your Goal

Use your knowledge of the standards to select footwear that addresses the actual risks of your environment.

- If your primary focus is general compliance: Look for footwear explicitly labeled as meeting ASTM F2413-18 and check the tag for the specific I/75 and C/75 ratings.

- If your environment has electrical risks: Verify the specific EH or SD rating on the label, as these are distinct and non-interchangeable protections.

- If you work with sharp ground-level hazards: Ensure the footwear has the Puncture Resistant (PR) designation marked clearly on the label.

- If slips and falls are your main concern: Seek out footwear that is also certified to the newer ASTM F3445-21 slip resistance standard, in addition to any other required protections.

Understanding these standards empowers you to look beyond the marketing and select footwear that provides comprehensive, targeted protection for your specific work environment.

Summary Table:

| Protection Type | ASTM Code | Key Feature |

|---|---|---|

| Impact/Compression | I/C | Protective toe cap |

| Metatarsal | Mt | Guards the top of the foot |

| Electrical Hazard | EH | Protection from open circuits |

| Puncture Resistance | PR | Plate protects sole from sharp objects |

| Slip Resistance* | F3445-21 | Separate standard for traction |

| *Note: Slip resistance is not part of F2413-18 but is covered by ASTM F3445-21. |

Need compliant safety footwear for your workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified safety shoes and boots for distributors, brand owners, and bulk clients. We ensure every pair meets the precise performance requirements of standards like F2413-18, providing the protection your team needs.

Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- Why is impact and puncture resistance a critical feature for fishing footwear? Protect Your Crew from Deck Hazards

- What are metatarsal guards and what is their purpose in safety footwear? Protect Your Foot's Most Vulnerable Bones

- What role does the AMCR play in industrial safety shoe replacement? Optimize Footwear Lifecycles with Financial Data

- Why is chemical-resistant and waterproof footwear essential for manual car wash operations? Ensure Worker Safety

- What is an OSHA approved boot? The Truth About Compliant Safety Footwear

- What is the importance of puncture-resistant midsoles in safety shoes? Protect Workers from Industrial Hazards

- What are the main materials used in composite toe safety shoes? A Guide to Lightweight, Non-Metallic Protection

- Why should ergonomics and comfort be prioritized when selecting safety shoes? Boost Compliance & Worker Health