Understanding safety footwear ratings is the critical link between assuming you are safe and knowing you are protected. This knowledge empowers you to select footwear that provides adequate, specific protection against the real-world hazards you face on the job. It's the process of matching the shoe's certified capabilities to your workplace risks, ensuring compliance with standards from organizations like OSHA and ASTM.

The codes on a safety boot's tag are a direct language describing its specific protective capabilities. Misinterpreting these codes—or ignoring them entirely—means you could be wearing footwear that offers zero protection against the actual dangers you face daily.

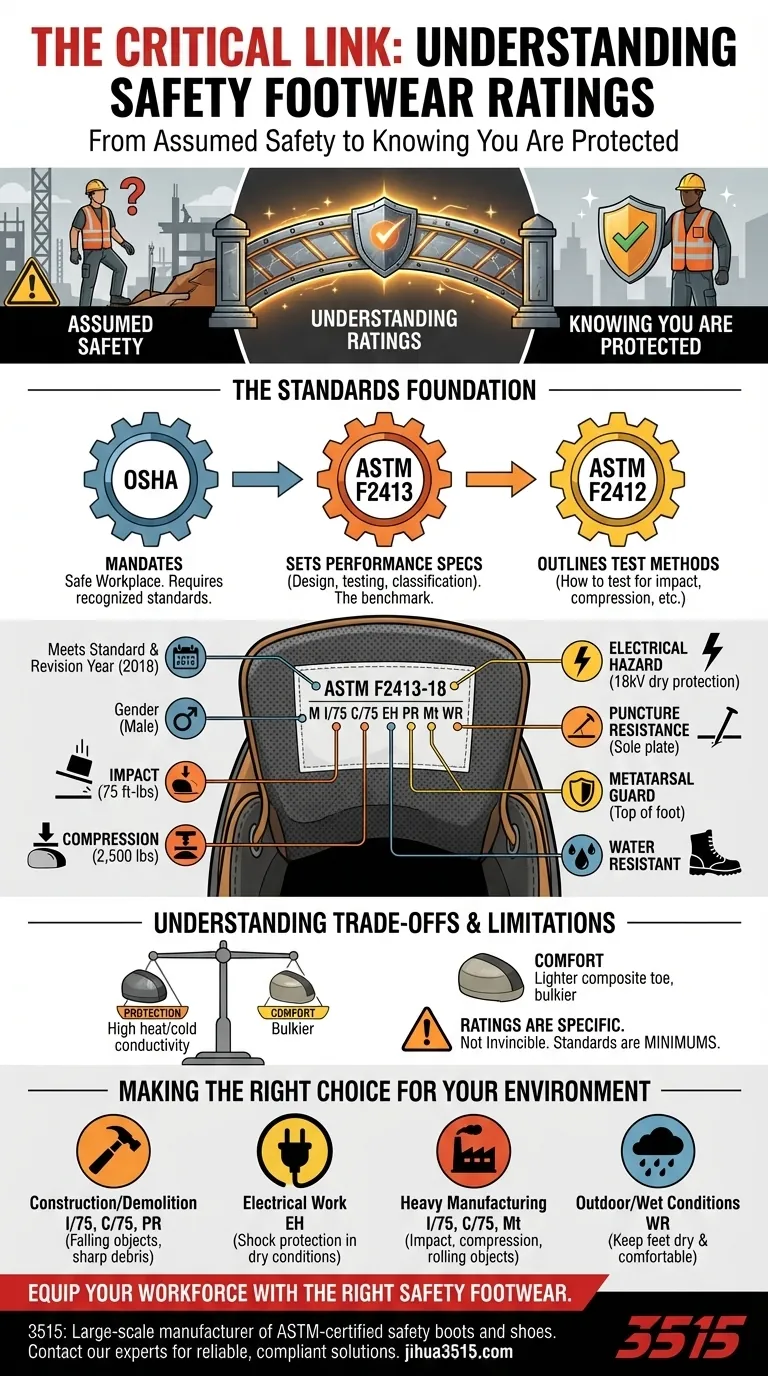

The Foundation: What Are the Standards?

To properly interpret a rating, you first need to understand the organizations and standards that govern safety footwear. They work together to create a system of testing and certification.

The Role of OSHA

The Occupational Safety and Health Administration (OSHA) mandates that employers ensure a safe workplace. This includes providing appropriate Personal Protective Equipment (PPE), but OSHA itself does not test or certify footwear. Instead, it requires that footwear meets or exceeds standards set by other recognized organizations.

The ASTM F2413 Standard

This is the key performance specification in the United States. ASTM F2413 establishes the minimum requirements for the design, performance, testing, and classification of protective footwear. When a boot says it meets this standard, it has passed a series of rigorous tests for specific hazards.

The ASTM F2412 Standard

This standard is the companion to F2413. ASTM F2412 outlines the test methods themselves. It details precisely how to perform tests for things like impact, compression, and puncture resistance, ensuring that every certified boot is evaluated in the exact same way.

Decoding the Safety Rating Label

The information you need is printed on a tag inside the boot, typically on or near the tongue. It follows a specific, multi-line format that is easy to read once you know the code.

The Standard Line-by-Line Format

A typical label will look like this:

Line 1: ASTM F2413-18

This line confirms the boot meets the performance requirements of the ASTM F2413 standard, with "-18" indicating the year of the standard's revision (2018).

Line 2: M I/75 C/75 EH

This is the most critical line. It identifies the gender the boot is for (Male or Female) and then lists the specific hazards it protects against.

Impact and Compression (I/75 C/75)

This is the most fundamental rating for safety-toe footwear.

- I/75 signifies the toe cap can withstand an impact of 75 foot-pounds.

- C/75 signifies it can withstand a compressive load of 2,500 pounds.

This combination is the standard for most "steel toe" or "composite toe" boots and protects against falling objects and crushing forces.

Electrical Hazard (EH)

An EH rating indicates the footwear is made with non-conductive, electric shock-resistant soles and heels. It is designed to protect the wearer from open circuits of up to 18,000 volts under dry conditions. This rating is critical for electricians and maintenance workers.

Puncture Resistance (PR)

Footwear marked with PR includes a puncture-resistant plate positioned in the sole to protect the foot from sharp objects like nails, glass, and scrap metal that could penetrate from below. This is essential on construction sites and in demolition environments.

Other Important Ratings

You may also encounter other codes for more specialized protection:

- Mt (Metatarsal): Includes a guard that protects the top of the foot.

- Cd (Conductive): Reduces the buildup of static electricity.

- SD (Static Dissipative): Regulates the buildup of static electricity.

- WR (Water Resistant): Indicates the footwear is designed to keep your feet dry.

Understanding the Trade-offs

Choosing the right boot isn't just about finding the highest rating; it's about understanding the practical implications of each feature.

Protection vs. Comfort

The material of the protective toe cap matters. Steel toes offer maximum protection but are heavy and conduct heat and cold. Composite toes (made of materials like Kevlar, carbon fiber, or plastic) are much lighter and don't conduct temperature, but can be bulkier to achieve the same rating.

A Rating Is Not "Invincible"

Each rating protects against a specific, tested threat. An EH-rated boot offers no protection from a nail if it isn't also rated PR. A boot with an I/75 C/75 toe cap will not protect you from the cutting force of a chainsaw. Always match the rating to the hazard.

Standards Set a Minimum

Remember that ASTM F2413 sets a minimum performance requirement. A boot must pass this baseline to be certified. While many manufacturers build footwear that far exceeds the standard, the label only confirms that it has met the required threshold.

Making the Right Choice for Your Environment

Use your knowledge of these ratings to perform a simple risk assessment of your job site and choose footwear that directly counters those risks.

- If your primary focus is construction or demolition: Prioritize footwear with I/75, C/75, and PR (Puncture Resistance) ratings to guard against falling objects and sharp ground debris.

- If your primary focus is electrical work: The EH (Electrical Hazard) rating is non-negotiable for protection against shock in dry conditions.

- If your primary focus is heavy manufacturing: Focus on I/75 and C/75 for impact and compression, and strongly consider Mt (Metatarsal) guards if objects could roll onto or strike the top of your foot.

- If your primary focus is working outdoors or in wet conditions: Look for the WR (Water Resistant) rating in addition to any other required safety features to ensure comfort and prevent foot ailments.

By learning to read the language of safety ratings, you take direct control over your personal safety at work.

Summary Table:

| Rating Code | What It Protects Against | Key Details |

|---|---|---|

| I/75 C/75 | Impact & Compression | Withstands 75 ft-lbs impact & 2,500 lbs compression (standard for steel/composite toes). |

| EH | Electrical Hazard | Protects against open circuits up to 18,000 volts in dry conditions. |

| PR | Puncture Resistance | Plate in sole protects against nails, glass, and sharp objects from below. |

| Mt | Metatarsal | Guard protects the top of the foot from rolling or falling objects. |

| WR | Water Resistant | Designed to keep feet dry in wet or outdoor environments. |

Ensure your workforce is equipped with the right safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, including styles with I/75 C/75, EH, PR, Mt, and WR ratings, tailored to your specific industry hazards. Don't leave safety to chance—contact our experts today to discuss your requirements and get a quote for reliable, compliant safety footwear.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

People Also Ask

- How does the price of safety shoes vary? From €30 Basics to Specialized Protection

- What type of safety-toe boot is recommended for cold weather? Choose Composite Toes for Warmth

- How does a Reliability Block Diagram (RBD) enhance footwear stability? Engineering High-Performance Shoe Systems

- What are the management advantages of providing standardized safety boots? Boost Stability and Compliance

- What are the requirements for oilfield boots? Essential Safety & Durability Features

- Why is an Inertial Measurement Unit (IMU) integrated into smart assistive footwear? Unlocking Precision Navigation

- What are the primary protective functions of industrial safety shoes in pharmaceutical QC labs? Ensure Lab Safety

- Why is the selection of non-toxic materials a fundamental requirement for industrial-grade safety shoes? (A Full Guide)