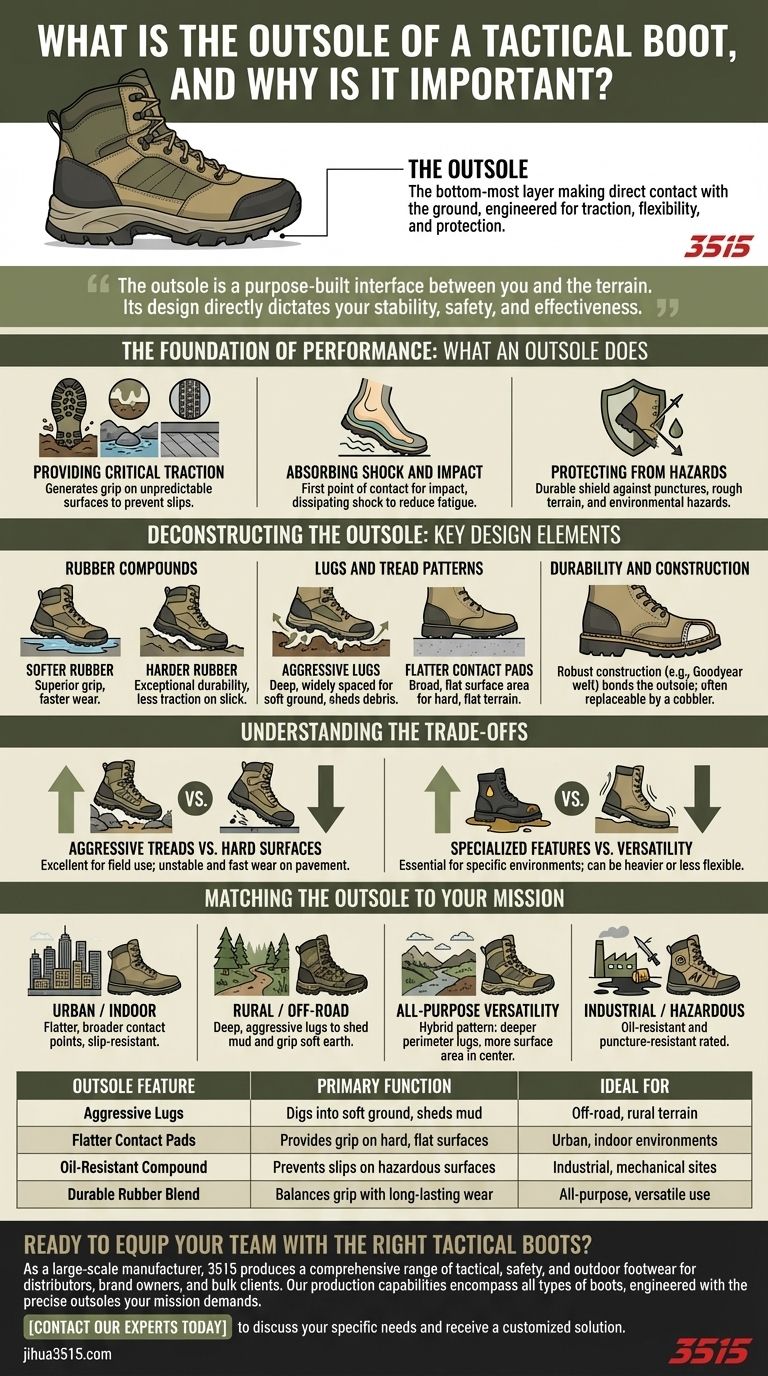

The outsole of a tactical boot is the bottom-most layer of the sole that makes direct contact with the ground. It is almost always made of a durable rubber compound and is engineered to provide traction, flexibility, and protection across demanding and unpredictable surfaces.

The outsole is far more than just the bottom of your boot; it is a purpose-built interface between you and the terrain. The design of its material, tread pattern, and durability directly dictates your stability, safety, and effectiveness in any given environment.

The Foundation of Performance: What an Outsole Does

A boot's outsole is the critical component responsible for how you interact with your surroundings. Its importance can be broken down into three primary functions.

Providing Critical Traction

The most fundamental job of an outsole is to generate grip. Tactical environments are rarely uniform, requiring a sole that can perform on everything from mud and gravel to wet rocks and oily industrial floors.

The specific rubber compound and tread pattern are designed to prevent slips, ensuring stable footing when it matters most.

Absorbing Shock and Impact

While the insole and midsole handle much of the cushioning, the outsole is the first point of contact for impact.

Its thickness and material density play a key role in dissipating initial shockwaves from walking or running, reducing fatigue on your feet, knees, and back over long periods.

Protecting from Hazards

The outsole serves as a durable shield between your foot and the ground. It protects you from punctures from sharp objects, rough terrain, and other environmental hazards.

Specialized outsoles can also offer resistance to oil, chemicals, or extreme temperatures, depending on their intended use.

Deconstructing the Outsole: Key Design Elements

Not all outsoles are created equal. Their performance is dictated by the specific materials and design features used in their construction.

The Role of Rubber Compounds

The type of rubber used is a critical choice. Softer rubber compounds tend to offer superior grip, especially on smooth or wet surfaces, but they wear down more quickly.

Harder rubber compounds provide exceptional durability and longevity but may offer less traction on slick terrain. Many outsoles use a blend to balance these two qualities.

Lugs and Tread Patterns

The "lugs" are the deep indentations and protrusions that make up the tread pattern. The design of these lugs is highly intentional.

Deep, widely spaced lugs are ideal for soft ground like mud or sand, as they dig in for grip and easily shed debris.

Broad, flatter contact pads provide more surface area for grip on hard, flat terrain like concrete or rock.

Durability and Construction

The outsole is the part of the boot exposed to the most wear and tear. High-quality tactical boots use robust construction methods, like a Goodyear welt, to securely bond the outsole to the rest of the boot.

On many premium boots, a worn-down outsole can be replaced by a cobbler, significantly extending the overall lifespan of the footwear.

Understanding the Trade-offs

Choosing the right outsole involves understanding its inherent compromises. A design that excels in one area may be a liability in another.

Aggressive Treads vs. Hard Surfaces

An outsole with deep, aggressive lugs is excellent for trail or field use but can feel unstable and wear down quickly on pavement. The reduced surface area can also make it less effective on smooth, flat ground.

Specialized Features vs. Versatility

An oil-resistant outsole is a non-negotiable feature in many industrial or mechanical environments. However, the specific rubber compound required might be heavier or less flexible than a standard outsole designed for general use.

Matching the Outsole to Your Mission

To make an informed decision, you must first define the environment where you will spend most of your time.

- If your primary focus is urban or indoor environments: Look for outsoles with flatter, broader contact points and slip-resistant properties for concrete and slick floors.

- If your primary focus is rural or off-road terrain: Prioritize boots with deep, aggressive lugs designed to shed mud and grip soft earth.

- If your primary focus is all-purpose versatility: Seek a hybrid tread pattern that balances deeper lugs on the perimeter with more surface area in the center.

- If your primary focus is industrial or hazardous sites: Ensure the outsole is specifically rated as oil-resistant and puncture-resistant.

Ultimately, selecting the right outsole is about ensuring your boots are a reliable tool, not a liability.

Summary Table:

| Outsole Feature | Primary Function | Ideal For |

|---|---|---|

| Aggressive Lugs | Digs into soft ground, sheds mud | Off-road, rural terrain |

| Flatter Contact Pads | Provides grip on hard, flat surfaces | Urban, indoor environments |

| Oil-Resistant Compound | Prevents slips on hazardous surfaces | Industrial, mechanical sites |

| Durable Rubber Blend | Balances grip with long-lasting wear | All-purpose, versatile use |

Ready to equip your team with the right tactical boots for any terrain?

As a large-scale manufacturer, 3515 produces a comprehensive range of tactical, safety, and outdoor footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of boots, engineered with the precise outsoles your mission demands—from urban patrol to rugged off-road use.

Contact our experts today to discuss your specific needs and receive a customized solution.

Visual Guide

Related Products

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

People Also Ask

- What is the relationship between footwear design and the effectiveness of biomechanical alignment? Maximize Stability

- How do specialized training shoes and sneakers support high-intensity training? Maximize Performance & Stability

- How can high-quality tactical or athletic footwear mitigate social participation restrictions? Enhance Your Mobility

- What key functions do professional Training Shoes perform? Maximize Stability and Power in High-Load Lifting

- Why are professional training shoes critical for safety? Expert Guide to Plyometric Stability and Performance