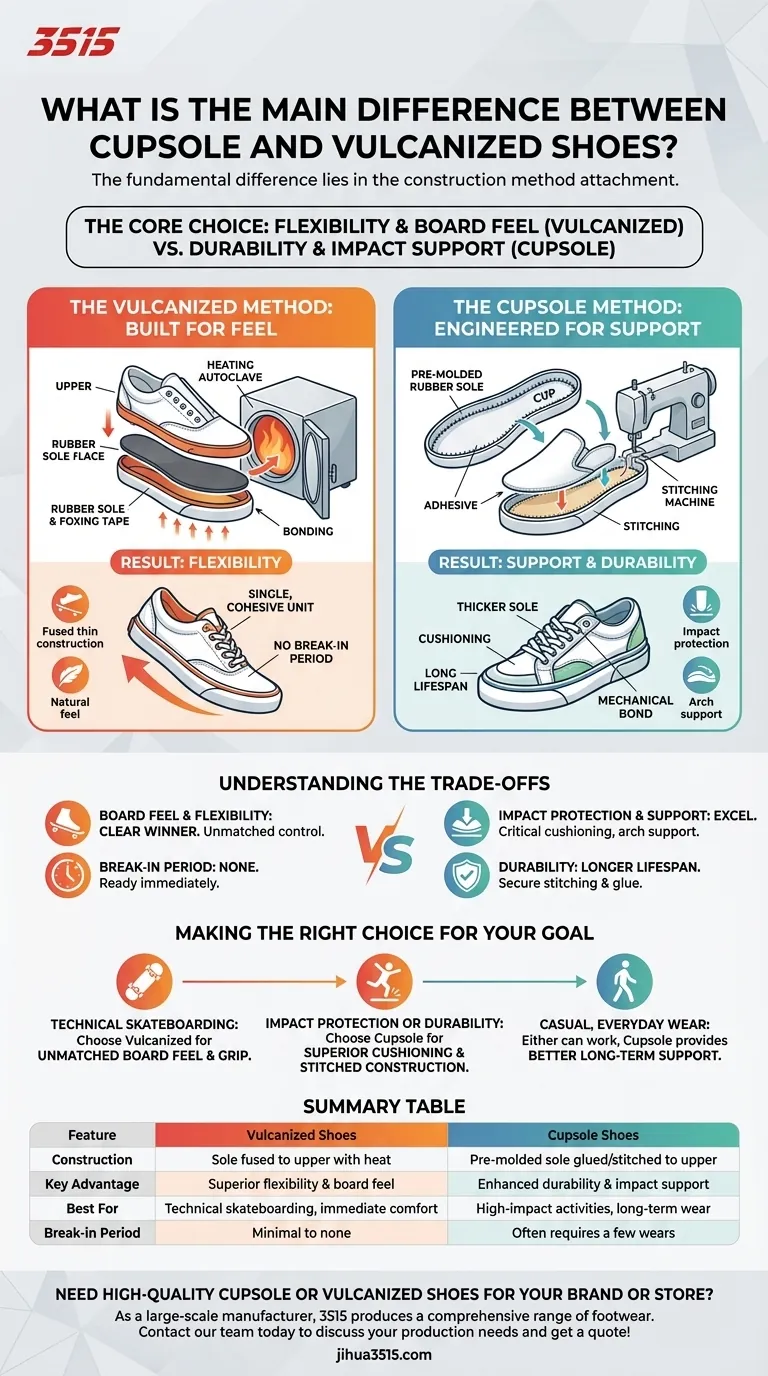

The fundamental difference between cupsole and vulcanized shoes lies entirely in the construction method used to attach the rubber sole to the upper part of the shoe. A vulcanized sole is bonded to the upper using heat, creating a flexible, one-piece-like construction. In contrast, a cupsole is a thicker, pre-molded sole that is either glued or stitched to the upper, forming a more durable and supportive foundation.

At its core, the choice between cupsole and vulcanized construction is a trade-off between two distinct priorities: flexibility and board feel (vulcanized) versus durability and impact support (cupsole).

The Vulcanized Method: Built for Feel

A vulcanized shoe feels like a single, cohesive unit right out of the box. This is a direct result of its unique manufacturing process.

The Heating and Bonding Process

In vulcanization, a soft rubber sole is attached to the shoe's upper with a rubber foxing tape. The entire shoe is then heated in a large oven, or autoclave, which causes the rubber to harden and permanently bond all the pieces together.

This process essentially "bakes" the shoe into its final form, creating a very strong chemical bond.

The Result: Flexibility

Because the sole is fused directly to the upper, vulcanized shoes are incredibly flexible and require almost no break-in period. This pliability is what gives them their signature "board feel," which is highly valued in activities like skateboarding.

The Cupsole Method: Engineered for Support

Cupsole construction is a more traditional and robust method of shoemaking, prioritizing structure and protection over pure flexibility.

The "Cup" and Stitching Method

A cupsole is named for its shape: a pre-molded rubber sole with a tall sidewall that forms a "cup" for the upper to sit inside. This cup is then attached to the upper using industrial-strength adhesives and is often reinforced with stitching along the perimeter.

This two-part construction—upper and separate sole unit—is what defines the cupsole design.

The Result: Support and Durability

The thicker, pre-molded rubber of a cupsole offers significantly more cushioning and impact absorption than a vulcanized sole. The addition of stitching also creates a more durable mechanical bond, making the shoe less prone to separating at the seams over time.

Understanding the Trade-offs

Neither construction method is inherently better; they simply serve different purposes. The right choice depends entirely on your intended use.

Board Feel and Flexibility

Vulcanized shoes are the clear winner here. Their fused, thin construction allows your foot to feel the board or ground beneath you, offering superior control and a natural feel from the very first wear.

Impact Protection and Support

Cupsoles excel in this category. The thicker sole and often-included midsoles provide critical cushioning that protects your feet from hard landings and provides better arch support for all-day wear.

Durability

Cupsoles generally have a longer lifespan. The combination of glue and stitching provides a very secure bond that is more resistant to the wear and tear that causes vulcanized soles to peel away from the upper.

Break-in Period

Vulcanized shoes are ready to go immediately. Their inherent flexibility means there is virtually no break-in time required. Cupsoles, being stiffer, often require a few wears to soften up and conform to your foot.

Making the Right Choice for Your Goal

Your activity should guide your decision. By understanding the functional differences, you can select the shoe that truly meets your needs.

- If your primary focus is technical skateboarding: Choose a vulcanized shoe for its unmatched board feel and grip.

- If your primary focus is impact protection or durability: Choose a cupsole for its superior cushioning and robust, stitched construction.

- If your primary focus is casual, everyday wear: Either can work, but a cupsole will often provide better long-term support for walking.

Understanding this core construction difference empowers you to choose footwear that truly aligns with your performance needs and personal priorities.

Summary Table:

| Feature | Vulcanized Shoes | Cupsole Shoes |

|---|---|---|

| Construction | Sole fused to upper with heat | Pre-molded sole glued/stitched to upper |

| Key Advantage | Superior flexibility & board feel | Enhanced durability & impact support |

| Best For | Technical skateboarding, immediate comfort | High-impact activities, long-term wear |

| Break-in Period | Minimal to none | Often requires a few wears |

Need high-quality cupsole or vulcanized shoes for your brand or store?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring you get the perfect construction, quality, and pricing for your market.

Contact our team today to discuss your production needs and get a quote!

Visual Guide

Related Products

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- What is the relationship between footwear design and the effectiveness of biomechanical alignment? Maximize Stability

- What role do professional training shoes play during HIIT for adolescent athletes? Stability and Injury Prevention

- What is the benefit of using a multi-functional training station for CRT? Maximize Efficiency & Metabolic Health

- How does the integration of advanced functional composite materials in Training and Outdoor shoes protect market share?

- What key functions do professional Training Shoes perform? Maximize Stability and Power in High-Load Lifting