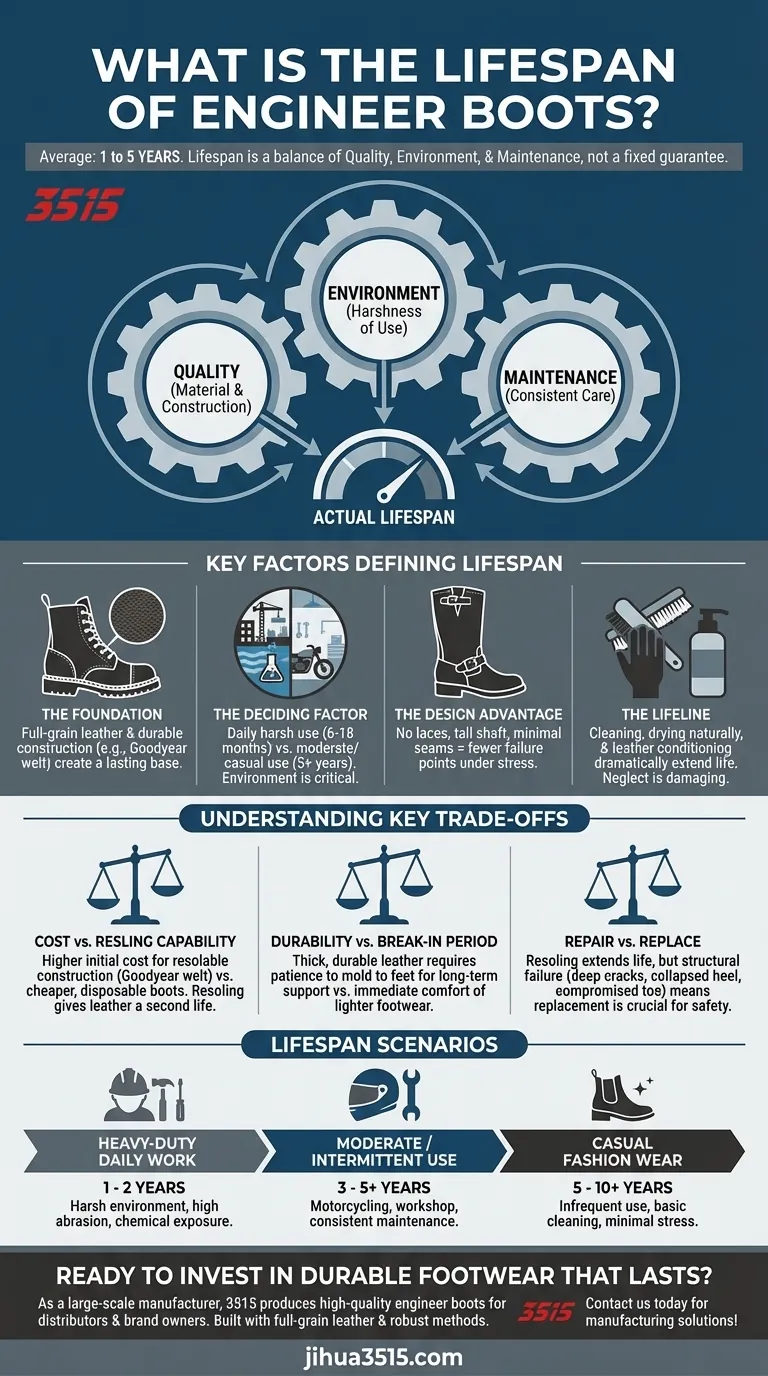

On average, a pair of high-quality engineer boots will last between 1 and 5 years. This wide range is because their ultimate lifespan is less about a fixed timeline and more about the specific demands placed upon them. Key factors like the quality of the leather, the harshness of your work environment, and your commitment to maintenance will determine whether your boots last a single year or become a long-term companion.

Engineer boots are built with durability as a core principle. Their actual lifespan, however, is not a fixed guarantee but a direct reflection of their construction quality, the intensity of their use, and the consistency of their care.

What Defines an Engineer Boot's Lifespan?

The longevity of any footwear is a balance of several critical elements. For engineer boots, these factors are especially pronounced due to their specific design and intended use.

The Foundation: Material and Construction

The starting point for a long life is the quality of the boot itself. Top-tier engineer boots use full-grain leather and durable construction methods, creating a foundation that can withstand years of stress. Cheaper materials will inevitably fail much sooner.

The Deciding Factor: Your Environment

This is the single most significant variable. Boots worn daily on a construction site, exposed to chemicals, water, and abrasion, may only last 6 to 18 months. The same pair worn for casual motorcycling or in a workshop could easily last 5 years or more.

The Design Advantage: Simplicity and Strength

Engineer boots have a distinct design advantage: no laces. This removes a common failure point found on other work boots. Their tall shaft, plain toe, and minimal seams mean there are fewer places for the boot to break down under stress.

The Lifeline: Consistent Maintenance

You have direct control over this factor. A simple routine of cleaning off dirt and mud, allowing the boots to dry naturally, and periodically applying a leather conditioner can dramatically extend their life. Neglect is as damaging as a harsh work environment.

Understanding the Key Trade-offs

Investing in high-quality engineer boots comes with considerations that go beyond the initial purchase price.

Cost vs. Resoling Capability

High-quality engineer boots are an investment. A significant part of that investment is in a construction method (like a Goodyear welt) that allows the boots to be resoled. This means you can replace a worn-out sole for a fraction of the cost of new boots, effectively giving the leather uppers a second or even third life.

Durability vs. Break-In Period

The thick, durable leather that gives engineer boots their longevity also requires a significant break-in period. Unlike lighter footwear, these boots demand patience as they mold to your feet. This initial discomfort is the trade-off for years of robust support.

When to Repair vs. When to Replace

While resoling can extend the life of the boot, it cannot fix structural failure. If the leather upper is deeply cracked, the heel counter has collapsed, or the steel toe has been compromised, it is time to replace the boot. Continuing to wear a structurally unsound boot is a safety hazard.

How to Maximize Your Investment

Your approach should be tailored to how you plan to use your boots.

- If your primary focus is heavy-duty daily work: Plan for a lifespan of 1-2 years and prioritize frequent cleaning and safety inspections.

- If your primary focus is moderate or intermittent use (e.g., motorcycling): With proper conditioning, you can realistically expect 3-5+ years of reliable service.

- If your primary focus is casual fashion wear: With minimal care, a well-made pair of engineer boots can easily last a decade or more.

Ultimately, the lifespan of your engineer boots is a partnership between their initial quality and your ongoing care.

Summary Table:

| Lifespan Scenario | Typical Duration | Key Influencing Factors |

|---|---|---|

| Heavy-Duty Daily Work | 1 - 2 years | Harsh environment, high abrasion, chemical exposure |

| Moderate/Intermittent Use | 3 - 5+ years | Motorcycling, workshop use, consistent maintenance |

| Casual Fashion Wear | 5 - 10+ years | Infrequent use, basic cleaning, minimal stress |

Ready to Invest in Durable Footwear That Lasts?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality engineer boots for distributors, brand owners, and bulk clients. Our expertise ensures every pair is built with durable full-grain leather and robust construction methods designed for longevity.

We help you provide your customers with reliable footwear that stands up to demanding environments. Let's discuss your specific needs and how our production capabilities can deliver the durability and value you require.

Contact us today to request a quote or learn more about our manufacturing solutions!

Visual Guide

Related Products

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

People Also Ask

- When are employers not required to pay for safety shoes? Understand OSHA's payment exceptions.

- What type of personal protective equipment does OSHA require? A Guide to Hazard-Based Compliance

- What are the consequences of not wearing safety shoes? Protect Your Feet from Severe Workplace Injuries

- What makes oilfield boots versatile for other industries? Unpacking Their Cross-Industry Value

- What are the features of lace-up work boots? Achieve Maximum Safety and All-Day Comfort