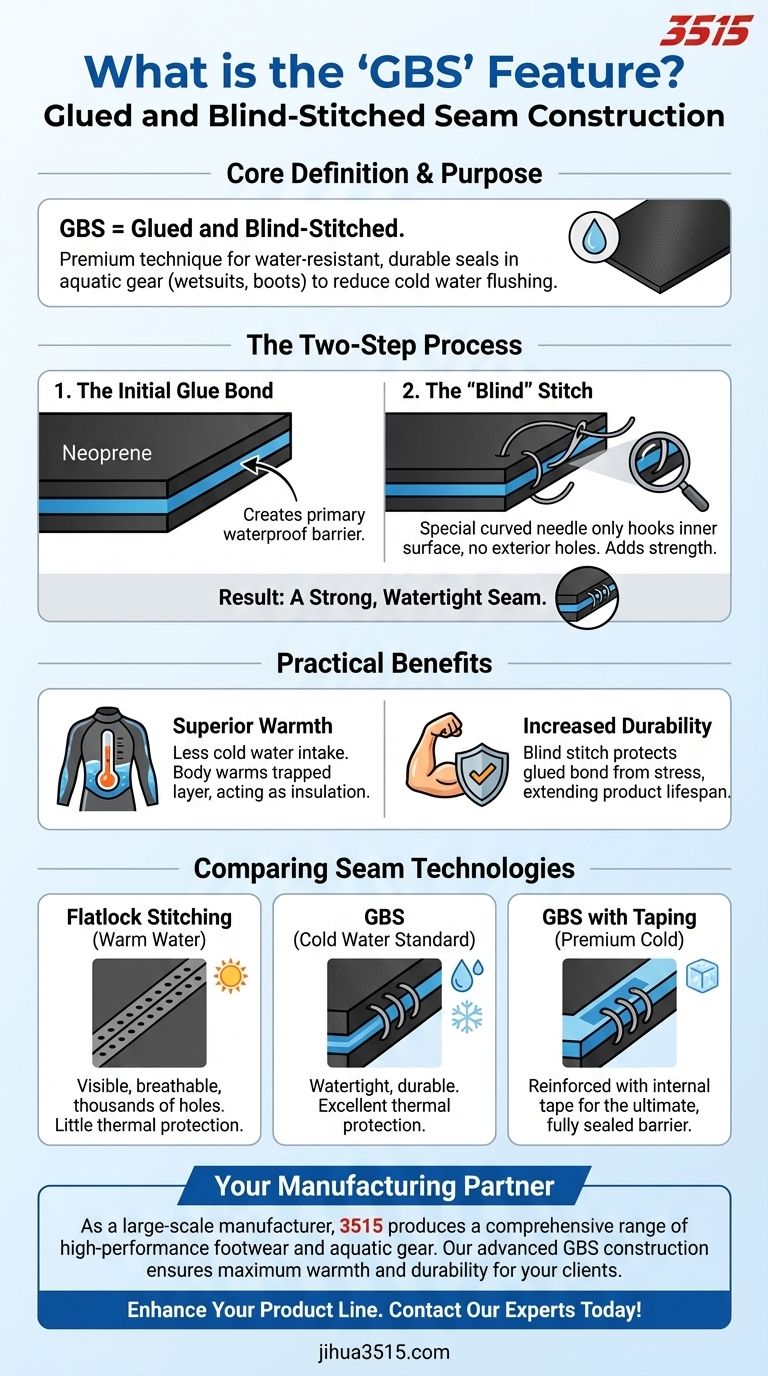

GBS stands for Glued and Blind-Stitched. It is a premium seam construction technique used in high-performance aquatic gear, like wetsuits and neoprene boots, to create a highly water-resistant and durable seal. The process involves first gluing the edges of the material together and then stitching them in a way that doesn't fully puncture the neoprene, drastically reducing water entry.

The core purpose of a Glued and Blind-Stitched seam is to minimize the flushing of cold water through your gear. This makes it a critical feature for anyone concerned with staying warm and comfortable during prolonged exposure to cool or cold water.

How GBS Construction Actually Works

Understanding the two-step process of GBS construction reveals why it is so effective at preventing water from seeping through the seams of a wetsuit or boot.

Step 1: The Initial Glue Bond

Before any stitching occurs, the edges of the neoprene panels are precisely cut and bonded together with a specialized, strong adhesive. This glue creates the primary waterproof barrier for the seam.

Step 2: The "Blind" Stitch

This is the key innovation. A special curved needle is used to stitch the seam, but it only passes partially through the neoprene. The needle hooks the inner surface of the material without piercing the exterior layer.

This "non-penetration" stitch adds significant strength and durability to the glued seam without creating the thousands of tiny holes found in more basic stitching methods.

The Result: A Strong, Watertight Seam

The combination of the waterproof glue and the reinforcing, non-penetrating stitch creates a final seam that is both incredibly strong and highly resistant to water leakage.

The Practical Benefits of GBS Seams

Choosing a product with GBS seams has direct and tangible impacts on performance, especially when it comes to thermal protection.

Superior Warmth

Less water entering your gear means your body has to heat less water. By preventing constant "flushing" of cold water, GBS seams allow the thin layer of trapped water to be warmed by your body, acting as an effective insulating layer.

Increased Durability

The blind stitch protects the glued seam from pulling apart under the stress of movement and stretching. This leads to a longer lifespan for the product, especially in high-stress areas like the shoulders and knees.

Understanding the Trade-offs: GBS vs. Other Seams

GBS is an excellent technology, but its value is best understood by comparing it to the alternatives you will find on the market.

GBS vs. Flatlock Stitching

Flatlock stitching is easily identifiable by its visible, railroad-track-like pattern. While comfortable and durable, this method involves stitching through both layers of neoprene, creating thousands of holes. It is perfectly suitable for warm water gear but offers very little thermal protection from water intrusion.

GBS with Seam Taping

For the highest level of performance, GBS seams are often reinforced with an internal tape (either fabric or a rubber-like "liquid tape"). This taping is applied over the blind stitch on the inside of the gear, sealing it completely and adding another layer of durability. This is the premium standard for cold-water equipment.

The Cost Factor

GBS is a more complex and labor-intensive construction method than flatlock stitching. Consequently, products featuring GBS seams are typically positioned at a higher price point, reflecting their superior performance and materials.

Making the Right Choice for Your Goal

The right seam technology depends entirely on the conditions you'll be facing.

- If your primary focus is warmth in cold water (below 60°F / 15°C): GBS is the minimum standard you should accept. For maximum performance, look for GBS combined with internal seam taping.

- If your primary focus is activity in warm, tropical water: A less expensive product with breathable flatlock seams is often more comfortable and entirely sufficient.

- If you need maximum durability and waterproofing for demanding conditions: Seek out gear that features GBS construction reinforced with full internal taping.

Understanding seam construction empowers you to invest in gear that is perfectly suited to the demands of your environment.

Summary Table:

| Feature | Benefit |

|---|---|

| Glued Seam | Creates a primary waterproof barrier. |

| Blind Stitch | Reinforces seam without creating water-entry holes. |

| Result | Superior warmth, durability, and water resistance. |

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear and aquatic gear for distributors, brand owners, and bulk clients. Our advanced production capabilities, including GBS construction, ensure your products offer maximum warmth, durability, and customer satisfaction. Let's discuss how we can enhance your product line — contact our experts today to get started!

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Durable Spiked Camouflage Boots Wholesale & Factory Production

- Premium KPU Athletic Safety Shoes for Wholesale

People Also Ask

- How does industrial 3D printing technology address production challenges in footwear? Overcome Design & Speed Barriers

- Why do leather fiber composites excel over pure recycled EVA in dynamic applications? Uncover Superior Durability & Damping!

- What materials are needed to clean leather cowboy boots? A Step-by-Step Guide to Proper Care

- How does the Vertical Stability Index (VSI) reflect the risk of falling? Analyze Balance & Impact on Slopes

- What is the primary function of an industrial padder in footwear fabric finishing? Ensure Uniform Protection

- How do physical components contribute to the professional image of sports events? Enhancing Brand Authority & Identity

- How did camouflage evolve during World War II? From Static Art to Mass-Produced Science

- What are the characteristics and considerations of using manual tools in footwear production? Precision vs. Ergonomics