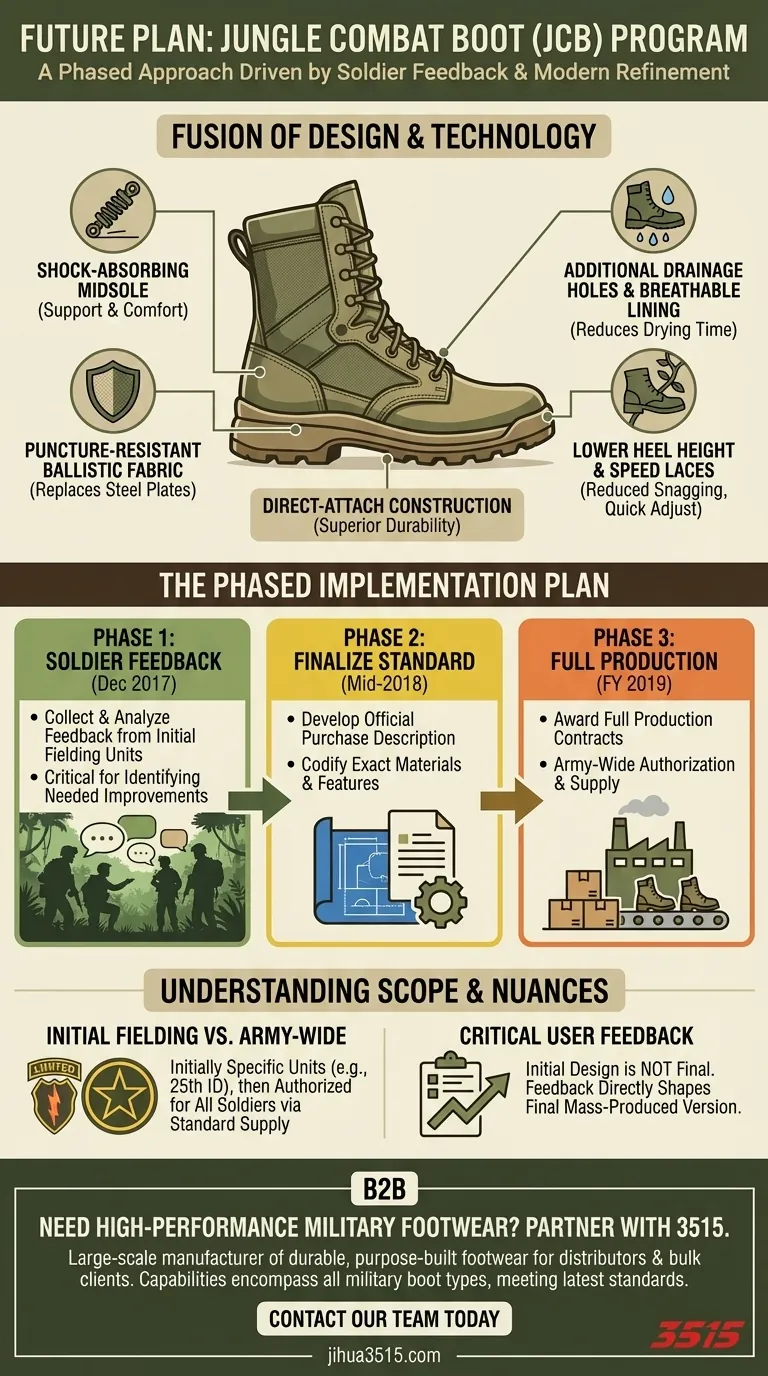

The future plan for the Jungle Combat Boot (JCB) program is a phased approach focused on user feedback and refinement before full-scale production. Following an initial fielding, the Army will collect soldier feedback to make final improvements, solidify the official design description by mid-2018, and then award full production contracts in fiscal year 2019 for Army-wide authorization.

The core strategy is not just to issue a new boot, but to use direct soldier feedback on a modern, purpose-built design to establish a new, fully authorized standard for jungle environments.

The Rationale Behind the New JCB

To understand the program's future, it's essential to understand its foundation. The JCB is not an entirely new concept but a deliberate evolution, blending a proven historical design with modern materials to solve specific environmental challenges.

Fusing Classic Design with Modern Technology

The new JCB starts with the successful DNA of the Vietnam-era M1966 "jungle boot," known for its "Panama style" mud-shedding outsole.

However, it integrates numerous technological upgrades. These include a shock-absorbing midsole for better support, a puncture-resistant ballistic fabric layer that replaces heavy steel plates, and a direct-attach construction for superior durability.

Solving Key Environmental Challenges

Every feature is designed to counter a specific jungle hazard.

Additional drainage holes, a breathable lining, and an improved water-draining insert work together to drastically reduce drying time and prevent water-logging. A lower heel height reduces the risk of snagging on vines and roots, while speed laces allow for quick adjustments in the field.

The Phased Implementation Plan

The Army is following a clear, methodical timeline to ensure the final product is validated by the end-user before it becomes a standard item. This multi-phase process is designed to mitigate risk and maximize effectiveness.

Phase 1: Soldier-Informed Refinement

The immediate next step is collecting soldier feedback in December. This is the most critical phase, as it provides the real-world data needed to determine if further improvements are required before finalizing the design.

Phase 2: Finalizing the Standard

Based on the soldier feedback, a final purchase description will be developed by mid-2018. This document codifies the boot's exact materials, features, and construction, transforming it from a test item into an official, procurable piece of equipment.

Phase 3: Transition to Full Production

The finalized description will be used to award full production contracts in fiscal year 2019. This marks the transition from limited fielding to making the JCB available through the standard supply system.

Understanding the Scope and Nuances

While the plan is straightforward, it's important to understand the specifics of the rollout and its implications for the force.

Initial Fielding vs. Army-Wide Authorization

The JCB will initially be issued only to specific units operating in jungle environments, such as those in the 25th Infantry Division.

However, once production begins, the boot will be authorized for wear by all soldiers. This means any soldier who obtains a pair through proper channels will be permitted to wear them, regardless of their unit or operational environment.

The Critical Role of User Feedback

The plan explicitly states that feedback will determine if further improvements are needed. This means the boot design seen in the initial fielding is not necessarily the final version. The final boot that goes into mass production may have subtle but important changes based directly on soldier experience.

What This Means for the Individual Soldier

The JCB program represents a significant upgrade in mission-specific footwear. Here is how to apply this information based on your role.

- If you are in a unit slated for initial fielding: Your feedback is the most critical factor influencing the final design that will be issued to the entire Army.

- If you are not in a unit receiving the initial issue: You can expect the JCB to become available for optional purchase and wear after production contracts are awarded in FY2019.

- If you are a leader or equipment manager: The mid-2018 finalization of the purchase description is the key milestone to watch for planning future equipment procurement.

Ultimately, this program is a deliberate shift toward providing soldiers with equipment that is precisely tailored to their operational environment.

Summary Table:

| Phase | Timeline | Key Action |

|---|---|---|

| 1. Soldier Feedback | December 2017 | Collect and analyze feedback from initial fielding units. |

| 2. Finalize Design | Mid-2018 | Develop the official purchase description based on feedback. |

| 3. Full Production | Fiscal Year 2019 | Award contracts for Army-wide authorization and supply. |

Need High-Performance Military Footwear? Partner with 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and purpose-built footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of military boots, including designs that meet the latest standards for specialized environments.

We can help you deliver the quality and reliability that soldiers depend on. Contact our team today to discuss your manufacturing needs.

Visual Guide

Related Products

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

People Also Ask

- What are the key components of a tactical boot? A Guide to Performance & Durability

- Why is lightweight and flexible material important in tactical footwear? Boost Endurance and Agility

- In what scenarios are tactical boots particularly useful? Maximize Mobility and Durability in Demanding Environments

- What are the main benefits of tactical boots? Superior Protection, Comfort & Durability

- What makes traction and stability important in tactical boots? Essential for Safety & Performance