The function of the outsole in tactical boots is to serve as the critical interface between you and the ground. It is the component engineered to provide essential grip for traction, a solid platform for stability, and durable protection against the terrain you operate in.

The outsole is not merely the bottom of the boot; it is a specialized tool. Its pattern, depth, and material composition are the primary factors determining your safety, stability, and overall effectiveness in the field.

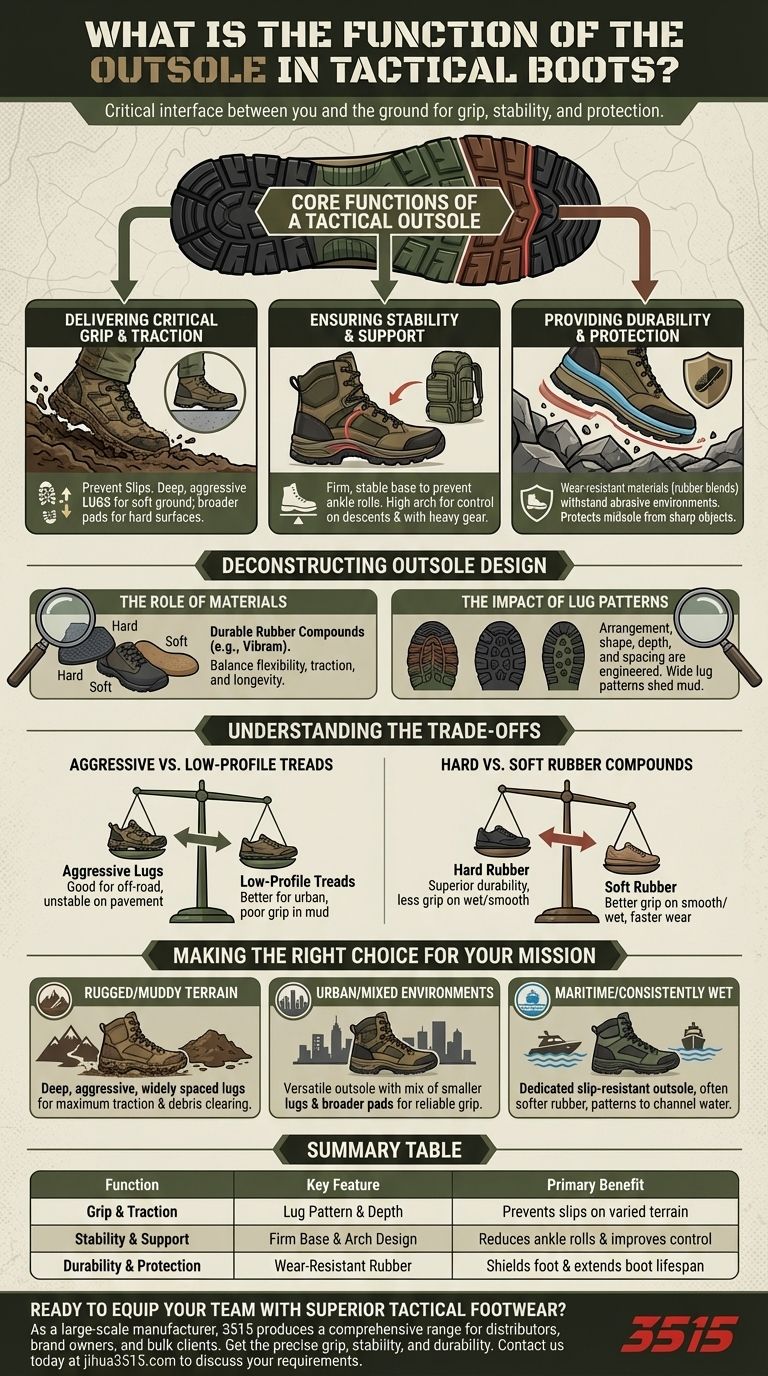

The Core Functions of a Tactical Outsole

A tactical boot's performance begins where it meets the ground. The outsole is responsible for translating your movement into effective, stable action, and its design directly impacts mission success and safety.

Delivering Critical Grip and Traction

The most fundamental job of the outsole is to prevent slips. It achieves this through carefully designed traction patterns, often called lugs.

Deep, aggressive lugs are designed to bite into soft or loose ground like mud, sand, and dirt. In contrast, broader pads increase surface contact for better grip on hard, flat surfaces like concrete or rock.

Ensuring Stability and Support

A well-designed outsole creates a firm, stable base that helps prevent ankle rolls and other injuries. It is the foundation for your entire posture.

The structure of the outsole, including features like a high, sharp arch, can provide additional control, especially when navigating steep descents or carrying heavy gear.

Providing Durability and Protection

Tactical environments are abrasive. The outsole must be made from wear-resistant materials, typically specialized rubber blends, to withstand punishment without failing.

This durable layer also protects the softer midsole from sharp objects and constant impact, extending the life of the boot and protecting your foot.

Deconstructing Outsole Design

The effectiveness of an outsole comes down to two key elements: the materials it's made from and the physical pattern of its tread.

The Role of Materials

Most tactical outsoles are made from durable rubber compounds. High-performance brands like Vibram are often used for their proven ability to balance flexibility, traction, and longevity.

The material must be tough enough to resist wear while remaining flexible enough to allow for natural foot movement and grip on varied surfaces.

The Impact of Lug Patterns

The arrangement of the tread is not arbitrary. Wide lug patterns are specifically designed to shed mud and debris, preventing the outsole from becoming clogged and losing traction.

The shape, depth, and spacing of the lugs are all engineered to maximize grip on the intended terrain, whether it's wet, slippery, or uneven.

Understanding the Trade-offs

No single outsole design is perfect for every situation. Understanding the inherent compromises is key to selecting the right boot.

Aggressive vs. Low-Profile Treads

An outsole with deep, aggressive lugs is ideal for rugged, off-road conditions but can feel unstable and wear down quickly on pavement.

Conversely, a lower-profile tread designed for urban environments will not provide sufficient grip in thick mud or on slippery trails.

Hard vs. Soft Rubber Compounds

A harder rubber compound offers superior durability and will last longer, especially on abrasive surfaces like concrete or asphalt.

However, a softer rubber compound typically provides better grip, particularly on smooth, wet surfaces, at the cost of faster wear.

Making the Right Choice for Your Mission

Your boot's outsole should be chosen as a specific tool for the job at hand. Consider your most common operational environment.

- If your primary focus is rugged or muddy terrain: You need an outsole with deep, aggressive, and widely spaced lugs for maximum traction and debris clearing.

- If your primary focus is urban or mixed environments: Look for a versatile outsole with a mix of smaller lugs and broader surface pads for reliable grip on both pavement and occasional soft ground.

- If your primary focus is maritime or consistently wet conditions: Prioritize a dedicated slip-resistant outsole, often featuring a softer rubber and patterns designed to channel water away.

Choosing the right outsole means matching the boot's design to your specific operational environment, ensuring every step is secure and effective.

Summary Table:

| Function | Key Feature | Primary Benefit |

|---|---|---|

| Grip & Traction | Lug Pattern & Depth | Prevents slips on varied terrain (mud, rock, concrete). |

| Stability & Support | Firm Base & Arch Design | Reduces ankle rolls and improves control under load. |

| Durability & Protection | Wear-Resistant Rubber | Shields the foot and extends the boot's lifespan. |

Ready to equip your team with superior tactical footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of tactical boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of mission-specific footwear, ensuring your team gets the precise grip, stability, and durability they need.

Contact us today to discuss your requirements and leverage our manufacturing expertise.

Visual Guide

Related Products

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- High-Traction Suede Tactical Boots Wholesale & Custom Manufacturing

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

People Also Ask

- What safety standards should firefighting boots meet? NFPA 1971 Compliance for Maximum Protection

- What are the advantages of lightweight tactical boots? Enhanced Speed, Agility & Reduced Fatigue

- Who typically uses tactical boots? Essential Footwear for Professionals on the Move

- How do professional tactical boots support performance? Enhance Stability & Speed in High-Pressure Tasks

- How does the weight of tactical boots affect movement? Find the Perfect Balance for Your Mission

- What is the significance of using professional tactical boots for motion tracking? Ensure Data Precision & Stability

- How do tactical boots and combat boots compare in terms of comfort? A Guide to Choosing the Right Footwear

- What are the advantages of industrial production lines for tactical boots? Achieve Consistency and Scale