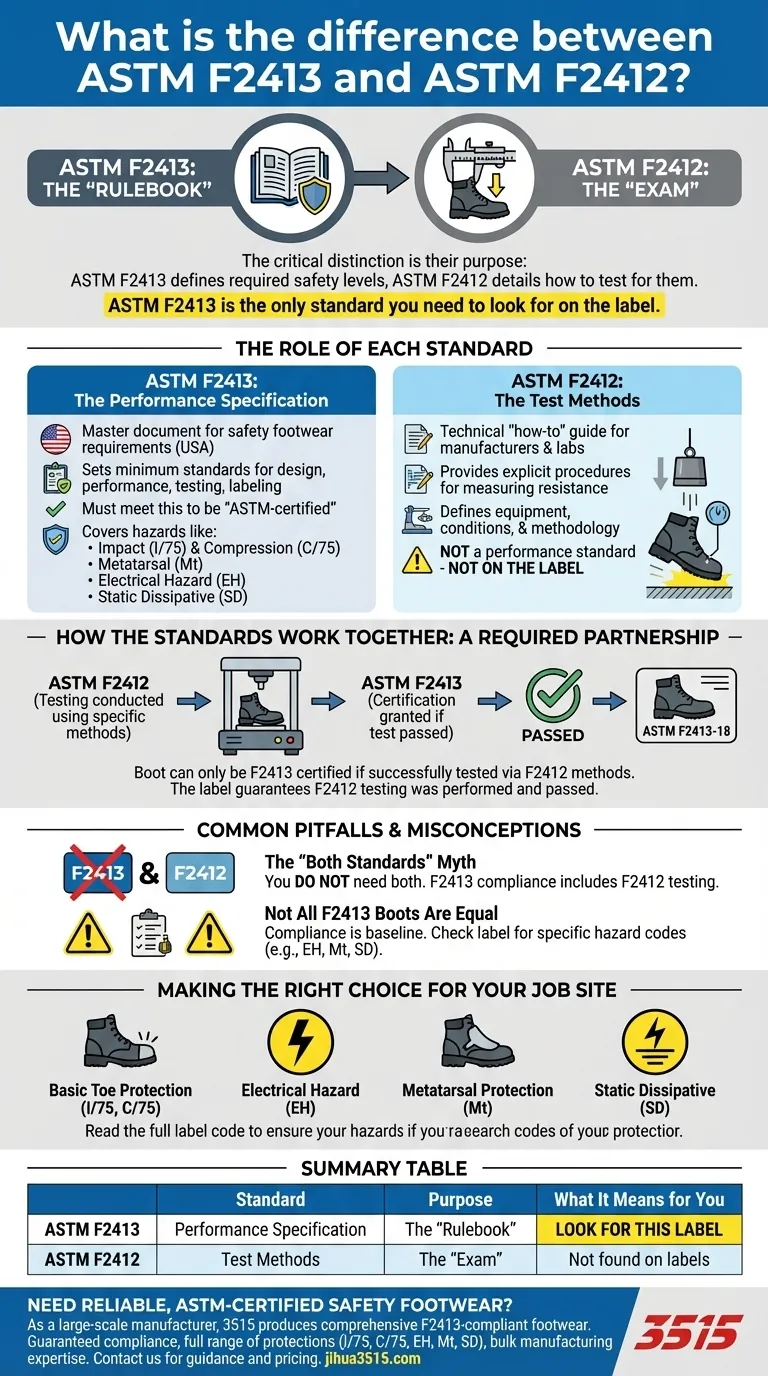

The critical distinction between these two standards is their purpose. ASTM F2413 is the performance specification that safety footwear must meet, defining the required levels of protection. ASTM F2412 is the corresponding standard that details exactly how to test footwear to see if it meets those requirements. For anyone selecting or wearing safety boots, ASTM F2413 is the only standard you need to look for on the label.

Think of ASTM F2413 as the "rulebook" that defines what makes a boot safe, and ASTM F2412 as the "exam" a boot must pass to prove it. A boot that is certified to F2413 has already passed the F2412 exam.

The Role of Each Standard

To select the right footwear, it's essential to understand what each standard governs. They are not competing standards; they are partners in a system designed to ensure worker safety.

ASTM F2413: The Performance Specification

This is the master document for safety footwear requirements in the United States.

It sets the minimum standards for design, performance, testing, and labeling. A boot cannot be sold as "ASTM-certified" safety footwear without meeting these specifications.

This standard covers a wide range of potential workplace hazards, including impact and compression resistance for the toe area, metatarsal protection (Mt), conductive protection (Cd), electrical hazard resistance (EH), and static dissipative properties (SD).

ASTM F2412: The Test Methods

This standard is the technical "how-to" guide used by manufacturers and testing laboratories.

It provides the explicit, detailed procedures for measuring resistance to impact and compression. It defines the equipment, conditions, and methodology for every test.

You will never see F2412 on a boot's label because it's not a performance standard. It is simply the method used to verify the performance requirements outlined in F2413.

How the Standards Work Together

The relationship between F2413 and F2412 is sequential and dependent. One cannot exist without the other.

A Required Partnership

A boot can only be certified to the F2413 standard if it has been successfully tested using the methods described in F2412.

F2413 states what level of protection the toe cap must provide (e.g., resist a 75 foot-pound impact). F2412 describes precisely how to drop the weight to conduct that test and measure the result.

Why You Only See "F2413" on the Boot

The label inside protective footwear shows that it meets the comprehensive performance specification.

When you see "ASTM F2413-18" on a label, it serves as a guarantee that the required F2412 testing was performed and passed. This simple marking conveys all the necessary information to the end-user.

Common Pitfalls and Misconceptions

The relationship between these standards can cause confusion, leading to incorrect assumptions about safety footwear.

The "Both Standards" Myth

You do not need to look for a boot that meets "both standards." A boot that is compliant with ASTM F2413 is, by definition, a boot that has passed the tests from ASTM F2412. The F2413 label is sufficient proof.

Not All F2413 Boots Are Equal

Compliance with F2413 is the baseline, but it doesn't mean every boot offers the same type of protection.

The standard includes codes for specific hazards. A boot can be F2413 certified for impact (I/75) and compression (C/75) but offer no protection against electrical hazards (EH) or falling objects on the top of the foot (Mt).

You must read the full line of code on the label to understand the specific protections a boot provides.

Making the Right Choice for Your Job Site

To ensure you have the proper protection, you must match the specific codes on the F2413 label to the hazards of your workplace.

- If your primary focus is basic toe protection: Look for any footwear marked with "ASTM F2413-18" followed by "I/75" and "C/75".

- If your primary focus is protection from live electrical circuits: You must also find the "EH" rating on the label in addition to the I/75 and C/75 ratings.

- If your primary focus is guarding against objects falling on the top of your foot: The "Mt" marking for metatarsal protection is essential.

- If your primary focus is preventing static discharge in a sensitive environment: You need footwear that carries the "SD" (static dissipative) rating.

Focusing on the specific protection codes within the F2413 label ensures you get the exact safety your job demands, not just the minimum.

Summary Table:

| Standard | Purpose | What It Means for You |

|---|---|---|

| ASTM F2413 | Performance Specification | The "rulebook." Defines the required safety levels (impact, electrical hazard, etc.). This is the label you look for. |

| ASTM F2412 | Test Methods | The "exam." Details how to test boots to prove they meet F2413 requirements. Not found on labels. |

Need Reliable, ASTM-Certified Safety Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM F2413-compliant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get the exact protection your workforce needs.

We provide:

- Guaranteed Compliance: All footwear meets or exceeds ASTM F2413 standards.

- Full Range of Protections: From basic impact/compression (I/75, C/75) to specialized EH, Mt, and SD ratings.

- Bulk Manufacturing Expertise: Scalable production to meet your volume demands efficiently.

Let's discuss your safety footwear requirements. Contact our team today for expert guidance and competitive pricing.

Visual Guide

Related Products

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

People Also Ask

- What types of toe protection are available in safety Wellington boots? Steel vs. Composite Toe Caps

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Why is the last important in work boot design? It's the Anatomical Blueprint for Comfort & Safety

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Do steel toe boots lack style options? Discover Modern, Stylish Safety Footwear