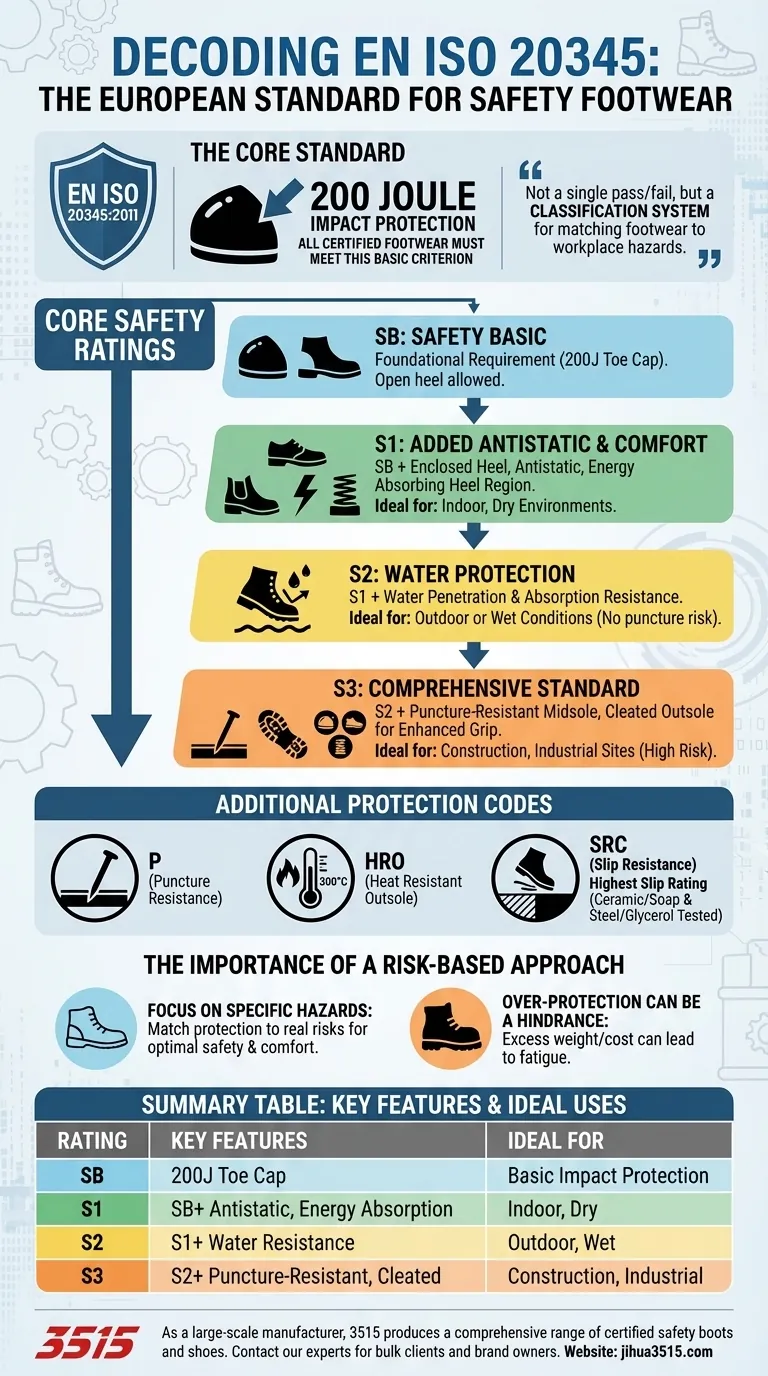

The definitive European standard for safety footwear is EN ISO 20345:2011. This regulation specifies the minimum requirements for professional safety footwear, with the most fundamental feature being toe protection capable of withstanding a 200-joule impact. All footwear certified under this standard must meet this basic criterion.

The key to understanding EN ISO 20345 is recognizing it's not a single "pass/fail" standard. Instead, it's a classification system with different rating codes (like S1, S2, and S3) that define escalating levels of protection, allowing you to match the footwear precisely to your specific workplace hazards.

Decoding the Core Safety Ratings

Every boot or shoe certified under EN ISO 20345 provides baseline protection, but the "S" codes indicate which additional protective features are included. Understanding these codes is the most critical step in selecting the correct footwear.

SB - The Basic Standard

SB stands for Safety Basic. This is the foundational requirement for any footwear to be classified as "safety" under the European standard.

It mandates only the 200-joule impact-resistant toe cap. Footwear marked as SB may have an open heel or other design variations not found in higher ratings.

S1 - Adding Antistatic Properties

An S1 rating includes all the features of SB, plus an enclosed heel, antistatic properties, and an energy-absorbing heel region.

This rating is ideal for indoor work in dry environments where there is a risk of falling objects but no risk of fluid splash or sharp objects underfoot.

S2 - Protection from Water

S2 footwear includes all the protective features of an S1 rating, but it also adds resistance to water penetration and absorption.

This makes S2 a suitable choice for outdoor work or any environment where you are likely to encounter wet conditions but do not require protection from sole puncture.

S3 - The Comprehensive Standard

The S3 rating is one of the most common and comprehensive classifications. It includes all the features of an S2 boot, plus a puncture-resistant midsole and a cleated outsole for enhanced grip.

This level of protection is essential for high-risk environments like construction sites, where workers face impact, water, and sharp object hazards simultaneously.

Understanding Additional Protection Codes

Beyond the primary "S" ratings, specific letter codes denote protection against specialized hazards. These are often combined with a primary rating (e.g., S3 HRO SRC).

P - Puncture Resistance

This indicates a midsole that is resistant to penetration from sharp objects like nails. While this is an integral part of the S3 rating, it can be added as an extra feature to an S1 boot, which would be designated S1 P.

HRO - Heat Resistant Outsole

An HRO marking signifies that the outsole can withstand contact with a hot surface at 300°C for one minute without melting or cracking. This is crucial for workers in industries like welding, road work, or foundries.

SRC - Slip Resistance

SRC is the highest rating for slip resistance. It indicates that the footwear has passed rigorous testing on both ceramic tile surfaces wetted with a soap solution (SRA) and steel floors with glycerol (SRB).

The Importance of a Risk-Based Approach

Simply choosing the highest-rated footwear (S3) is not always the best strategy. The goal is to match the protection to the specific and credible risks of your environment.

Over-Protection Can Be a Hindrance

An S3 boot is heavier and often less flexible than an S1 boot due to its midsole plate and additional water-resistant materials. For a warehouse worker in a dry environment, this extra weight and cost are unnecessary and can lead to fatigue.

Focusing on Specific Hazards

A risk assessment is your best tool. An electrician working indoors may prioritize antistatic properties (S1), while a road worker needs heat resistance (HRO) and puncture protection (S3). Focusing on the real hazards ensures optimal safety, comfort, and cost-effectiveness.

Making the Right Choice for Your Goal

Use your workplace risk assessment to determine the minimum protection you require.

- If your primary focus is indoor work with impact risk: An S1 boot provides the necessary toe protection and antistatic properties without the weight of unnecessary features.

- If your primary focus is outdoor or wet conditions without puncture risk: An S2 boot is the baseline to ensure your feet stay dry and protected from impact.

- If your primary focus is construction or industrial sites: An S3 boot is often the mandatory standard, offering comprehensive protection from impact, water, and sharp objects.

- If you need to verify existing footwear: Look for the "EN ISO 20345:2011" marking and the specific rating codes (e.g., S3 SRC) printed on the shoe's tongue or inner label.

Choosing the right safety footwear is about understanding the language of protection to match the right tool to the right risk.

Summary Table:

| Rating | Key Features | Ideal For |

|---|---|---|

| SB | 200-joule toe cap | Basic impact protection |

| S1 | SB + enclosed heel, antistatic, energy absorption | Indoor, dry environments |

| S2 | S1 + water resistance | Outdoor/wet conditions |

| S3 | S2 + puncture-resistant midsole, cleated outsole | Construction, industrial sites |

Need certified safety footwear that meets EN ISO 20345?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots and shoes for distributors, brand owners, and bulk clients. We ensure every pair meets the precise safety ratings your workforce requires, from S1 to S3 and specialized codes like HRO and SRC.

Let us help you equip your team with the right protection. Contact our experts today for competitive pricing and reliable supply.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

People Also Ask

- What regular maintenance checks should be performed on safety boots? A Daily Safety Checklist

- How long can you wear safety boots? The Lifespan is Determined by Wear, Not Time

- Why is moisture management a critical design feature for safety boots? Boost Mining Safety and Worker Skin Health.

- How should one choose safety boots based on workplace hazards? A Step-by-Step Guide to Perfect Protection

- What factors should be considered when choosing safety shoes for a specific work environment? Match Hazards to Certified Protection

- How durable are oil resistant safety boots? Built to Withstand Harsh Industrial Environments

- What role do professional work safety shoes play in health intervention? Enhance Physical Activity and Safety

- What role do industrial safety shoes play in feed production? Protect Your Workforce from Mechanical Hazards