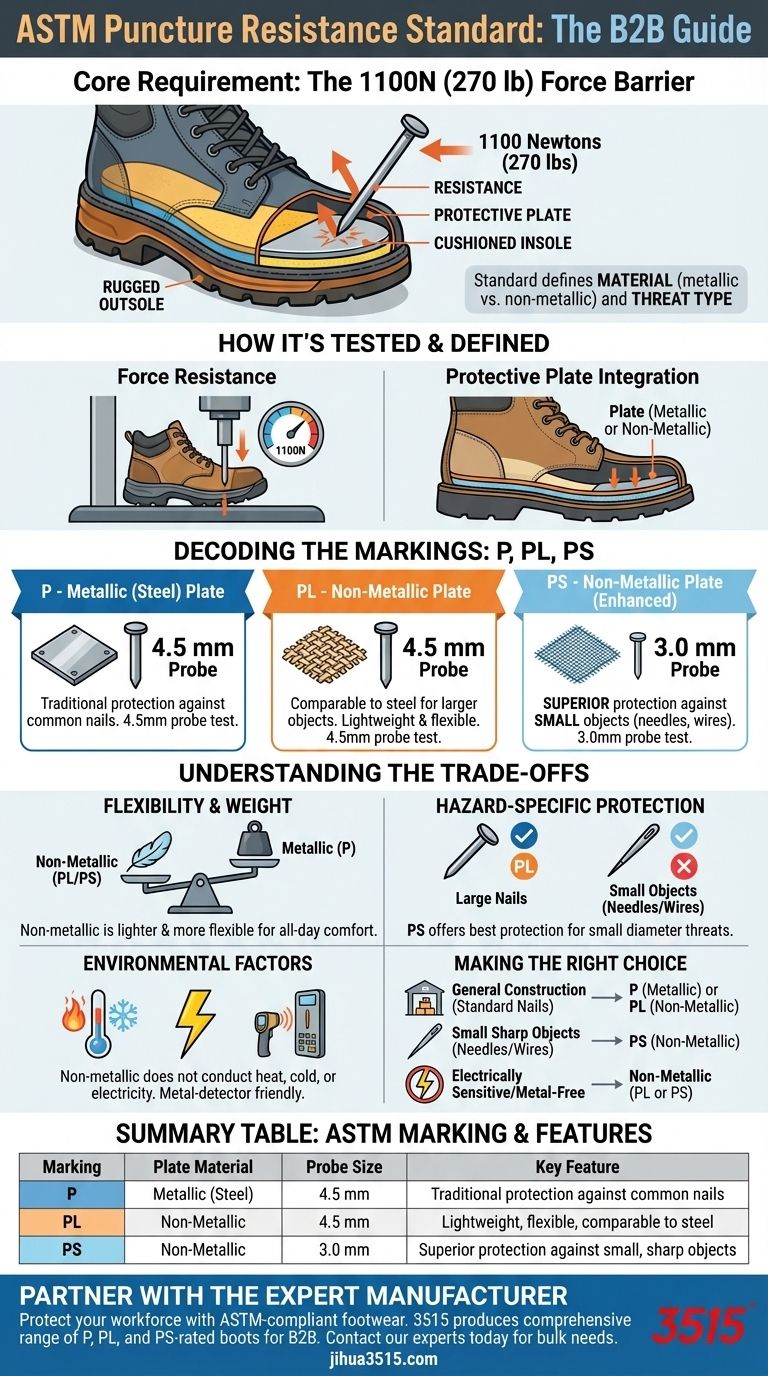

At its core, the ASTM standard for puncture-resistant footwear requires that the sole and heel area withstand a minimum penetration force of 270 pounds. This protection is provided by a specialized plate built permanently between the insole and outsole of the footwear.

The standard is not a single rating, but a system that defines the material used (metallic vs. non-metallic) and the specific type of threat it protects against, ensuring you can match your footwear to your environment's unique hazards.

How Puncture Resistance is Tested and Defined

To truly understand the standard, you must look beyond the single force number and see how the tests and materials give the rating its meaning.

The Fundamental Requirement: Force Resistance

The benchmark for all puncture-resistant footwear is its ability to resist a specific amount of force. The test involves pressing a standardized steel nail into the sole of the boot until a force of 1100 Newtons (approximately 270 pounds) is achieved without penetration.

The Protective Barrier: Built-in Plates

This resistance is not a property of the rubber sole itself. It comes from a puncture-resistant plate that is integrated into the boot's construction. This plate sits between the outsole (the part that touches the ground) and the insole (the part your foot rests on).

The Evolution of Materials

Traditionally, these plates were made of steel. However, modern footwear often uses non-metallic, high-strength woven materials like Aramid fibers. This shift led to an evolution in the testing standards to account for different material properties.

Decoding the Puncture Resistance Markings

The label on your safety footwear tells a precise story about its level of protection. The simple 'P' marking has been expanded to provide more clarity, especially for non-metallic plates.

Metallic Plates (P)

This is the traditional marking. It signifies that the footwear contains a steel plate. The test for this standard uses a probe with a 4.5 mm point, simulating a common construction nail.

Non-Metallic Plates (PL)

This marking indicates a non-metallic plate that has passed the test using the same large, 4.5 mm probe. This provides a comparable level of protection to steel against larger objects.

Non-Metallic Plates (PS)

This is a newer, more stringent standard for non-metallic plates. It signifies the plate has passed a test using a smaller, 3 mm probe. This was introduced because very small, sharp objects like needles or fine wires could potentially slip through the weave of some non-metallic fabrics.

Understanding the Trade-offs

Choosing between metallic and non-metallic protection involves weighing several key factors. There is no single "best" option—only the right option for a specific application.

Flexibility and Weight

Non-metallic plates are generally more flexible and lighter than their steel counterparts. This can significantly improve comfort over a long workday.

Hazard-Specific Protection

While both types protect against a 270-pound force, the nature of the threat matters. The 'PS' rating offers superior protection against smaller-diameter threats, a crucial factor in environments like waste management or recycling where hypodermic needles could be present.

Environmental Factors

Non-metallic plates do not conduct heat, cold, or electricity. This makes them the required choice for electricians or workers in extreme temperature environments. They also allow passage through metal detectors without issue.

Making the Right Choice for Your Goal

Selecting the correct footwear is a critical safety decision. Use the official markings to align the boot's capabilities with the known risks of your workplace.

- If your primary focus is general construction with risks from standard nails: Footwear marked with 'P' (metallic) or 'PL' (non-metallic) provides the necessary protection.

- If your primary focus is protection from smaller, sharper objects like wires or needles: You must select footwear with the 'PS' rating for reliable defense.

- If you work in an electrically sensitive or metal-free environment: Your only choice is footwear with non-metallic plates ('PL' or 'PS') to prevent conductivity.

By understanding these distinctions, you can confidently select footwear that provides the precise protection you need.

Summary Table:

| ASTM Marking | Plate Material | Probe Size | Key Feature |

|---|---|---|---|

| P | Metallic (Steel) | 4.5 mm | Traditional protection against common nails |

| PL | Non-Metallic | 4.5 mm | Lightweight, flexible, comparable to steel |

| PS | Non-Metallic | 3.0 mm | Superior protection against small, sharp objects |

Protect your workforce with the right ASTM-compliant footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of P, PL, and PS-rated safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities ensure you get durable, comfortable, and precisely certified footwear tailored to your specific workplace hazards. Contact our experts today for a consultation and discover how we can meet your bulk safety footwear needs.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- How should professional functional footwear, such as safety shoes and tactical boots, be optimized based on load-bearing gait research? For Enhanced Stability & Performance

- How is AI utilized in the design of outdoor and safety footwear? Harnessing Big Data for Market-Driven Shoe Innovation

- What are the main types of safety toes? Choose the Right Protection for Your Job

- What is the importance of high-strength midsoles in industrial safety footwear? Essential Puncture Protection for Sites

- What are the specific footwear requirements for maintenance on high-altitude water tanks? Essential Grip & Safety Guide

- How does the precision of an industrial-grade cutting machine affect safety shoe production? Ensure 100% Structural Integrity

- What is the purpose of the midsection with insert for ladder support in safety footwear? Enhance Stability & Safety

- Why are task-specific customized accessories necessary for specialized safety footwear? Boost Grip & Safety Now