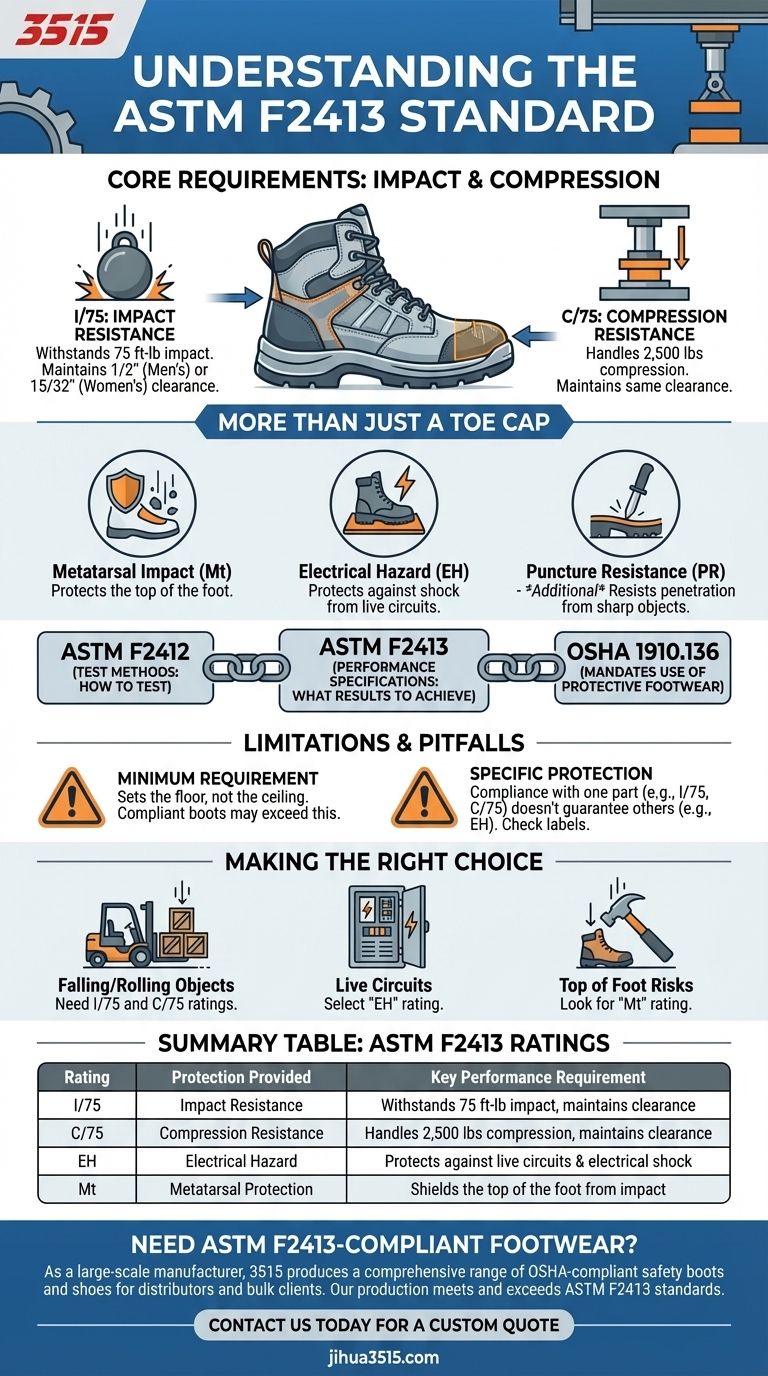

At its core, the ASTM F2413 standard is the primary U.S. performance specification for protective footwear. To meet this standard, a safety toe cap must be able to withstand a 75 foot-pound impact and 2,500 pounds of compression while maintaining a minimum interior clearance for the wearer's toes. This standard ensures a baseline level of protection against common workplace foot hazards.

The ASTM F2413 standard is more than a simple pass/fail test for a steel toe; it is a comprehensive set of performance requirements for footwear designed to protect against a variety of specific workplace dangers, from impact to electrical shock.

Deconstructing the ASTM F2413 Standard

The Two Core Requirements: Impact and Compression

The most recognized elements of the ASTM F2413 standard are the ratings for impact (I) and compression (C).

A boot labeled I/75 has been tested to protect the toes from an impact of 75 foot-pounds. During the test, it must retain a minimum clearance of a half-inch for men's footwear and 15/32 of an inch for women's.

A boot labeled C/75 has been tested to protect the toes from a compressive load of up to 2,500 pounds. Like the impact test, it must maintain the same minimum interior clearance to pass.

More Than Just a Toe Cap

While impact and compression resistance are foundational, the standard also specifies performance requirements for other critical hazards. Footwear must be clearly labeled to show which specific protections it offers.

These additional ratings address dangers such as metatarsal impact (Mt), which protects the top of the foot, and electrical hazard (EH), which protects against shock from live circuits.

How Standards Work Together: F2413 vs. F2412

You will often see two ASTM standards mentioned: F2413 and F2412. It's crucial to understand their distinct roles.

ASTM F2412 is the Standard Test Methods for Foot Protection. This document outlines how to perform the tests.

ASTM F2413 is the Standard Specification for Performance Requirements for Protective Footwear. This document defines what results a boot must achieve during those tests to be considered compliant.

The Connection to OSHA

The Occupational Safety and Health Administration (OSHA) mandates that employers protect workers from foot injuries.

OSHA's standard 1910.136 requires the use of protective footwear in hazardous environments. ASTM F2413 is the consensus standard that defines the level of performance this footwear must meet to be considered compliant.

Understanding the Limitations and Pitfalls

A Standard is a Minimum Requirement

ASTM F2413 establishes the baseline for safety. While all compliant boots meet this minimum, some manufacturers may design footwear that significantly exceeds these requirements. The standard sets the floor, not the ceiling, for performance.

Protection is Specific, Not Universal

A boot’s compliance with one part of the standard does not imply compliance with others. A boot rated for impact and compression (I/75, C/75) is not automatically rated for electrical hazards (EH). You must always check the boot's specific label for the protections you need.

The Myth of "OSHA-Approved"

OSHA does not "approve" or "certify" specific brands or models of safety footwear. Instead, OSHA sets the requirement that protective footwear must be used, and it is the employer's responsibility to select footwear that meets an appropriate standard, such as ASTM F2413.

Making the Right Choice for Your Goal

Selecting the correct boot requires matching its specific ASTM F2413 ratings to the known hazards of your work environment.

- If your primary focus is protection from falling objects or rolling equipment: Ensure the boot is clearly labeled with both I/75 and C/75 ratings.

- If your primary focus is working around live electrical circuits: You must select footwear specifically marked with the "EH" rating for its insulating properties.

- If your primary focus involves risks to the top of your foot (e.g., from dropped materials): Look for the "Mt" (Metatarsal) rating in addition to the standard toe protection.

Understanding these codes transforms a safety boot from a simple requirement into a specific tool chosen for your unique work environment.

Summary Table:

| ASTM F2413 Rating | Protection Provided | Key Performance Requirement |

|---|---|---|

| I/75 | Impact Resistance | Withstands 75 ft-lb impact, maintains toe clearance |

| C/75 | Compression Resistance | Handles 2,500 lbs compression, maintains toe clearance |

| EH | Electrical Hazard | Protects against live circuits and electrical shock |

| Mt | Metatarsal Protection | Shields the top of the foot from impact injuries |

Need ASTM F2413-Compliant Safety Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of OSHA-compliant safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear that meet and exceed ASTM F2413 standards, ensuring your workforce has the specific protection they need.

Contact us today to discuss your safety footwear requirements and get a custom quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What are the key features of motocross boots? Unpacking the Essential Safety Gear for Off-Road Riding

- Why is the use of professional safety shoes with chemical resistance essential during Mixed Bed Polisher regeneration?

- What are the advantages of water-based polyurethane spray coatings for safety shoe slip resistance? Enhanced Traction

- What are the advantages of textile penetration-resistant insoles? Lighter, More Flexible Foot Protection

- What role do industrial safety shoes play in feed production? Protect Your Workforce from Mechanical Hazards

- What is the overall importance of understanding safety footwear ratings? Ensure On-the-Job Protection

- What is the impact of electronic data synchronization on the assessment of protective footwear insoles?

- What special features do structural firefighting boots have to protect against heat? An Engineered Thermal Protection System