The primary lightweight alternatives to steel-toed boots that are safety-approved are composite toe and alloy toe boots. Both options significantly reduce the weight of the footwear while still meeting the same mandatory safety standards for impact and compression resistance required for a protective toe cap.

The choice is not simply about finding a lighter boot, but about understanding the specific trade-offs between steel, composite, and alloy materials. Your ideal boot depends entirely on your work environment, budget, and comfort priorities.

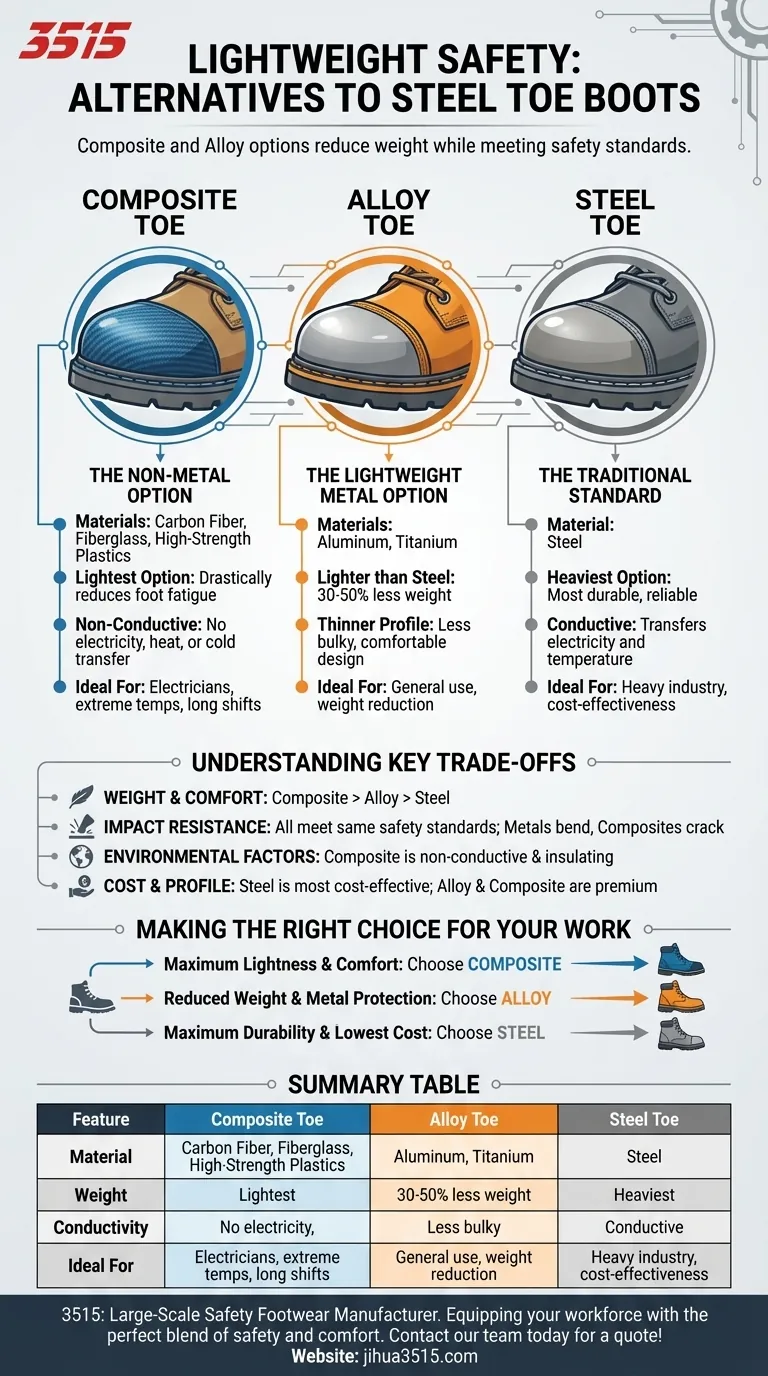

A Closer Look at the Alternatives

To select the right footwear, you must first understand the fundamental differences in the materials used for the protective toe cap. Each has distinct properties that make it suitable for different applications.

Composite Toe (The Non-Metal Option)

Composite toes are crafted from non-metal materials like carbon fiber, fiberglass, or high-strength plastics. They are the most modern innovation in safety footwear technology.

Their primary advantage is being the lightest option available, which drastically reduces foot fatigue over a long workday.

Because they contain no metal, they do not conduct electricity, heat, or cold. This makes them the superior choice for electricians or individuals working in extreme temperature environments.

Alloy Toe (The Lightweight Metal Option)

Alloy toes are typically made from lightweight metals such as aluminum or titanium. They offer a middle ground between traditional steel and modern composites.

These caps provide robust metal protection but are significantly lighter than steel, often by 30-50%.

Alloy caps can also be made thinner than steel caps while providing the same level of protection, which can result in a less bulky, more comfortable boot design.

Understanding the Key Trade-offs

While all three types must pass the same baseline safety tests (e.g., ASTM F2413 in the US), their material properties create important differences in performance, comfort, and cost.

Weight and Comfort

This is the most common reason for seeking an alternative. Composite toes are the lightest, followed by alloy, with steel being the heaviest. Less weight directly translates to less fatigue and greater comfort during long shifts.

Impact Resistance

All approved safety toes—steel, alloy, and composite—are rated to withstand the same minimum impact and compression forces.

However, after a single, severe impact, metal toes (steel and alloy) tend to bend but retain their shape, while a composite toe is more likely to crack or shatter. For this reason, any safety boot should be replaced after a significant impact event.

Environmental Factors

Composite toes are the clear winner for anyone working around live electrical circuits, as they are non-conductive.

They also provide superior insulation against extreme cold and heat, as the material does not readily transfer temperature to the foot.

Cost and Profile

Steel toe boots are generally the most cost-effective and widely available option.

Alloy and composite toe boots are considered premium features and often come at a higher price point. Alloy toes, in particular, can be among the more expensive options.

Making the Right Choice for Your Work

Selecting the correct safety boot is a matter of matching the material's strengths to your job's specific demands.

- If your primary focus is maximum lightness and comfort: Choose composite toe boots, especially if you walk long distances or need insulation from electricity or temperature.

- If your primary focus is reducing weight while preferring a metal toe cap: Choose alloy toe boots for a good balance of protection and reduced bulk.

- If your primary focus is maximum durability in a heavy industrial setting at the lowest cost: Traditional steel toe boots remain an excellent and reliable choice.

Ultimately, the best safety boot is the one that provides the specific protection you need with the comfort you want.

Summary Table:

| Feature | Composite Toe | Alloy Toe | Steel Toe |

|---|---|---|---|

| Material | Carbon Fiber, Fiberglass, Plastic | Aluminum, Titanium | Steel |

| Weight | Lightest | Lighter than Steel | Heaviest |

| Conductivity | Non-Conductive (Electricity, Heat/Cold) | Conductive | Conductive |

| Ideal For | Electricians, Extreme Temperatures, Long Shifts | General Use, Weight Reduction | Heavy Industry, Cost-Effectiveness |

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Whether you need lightweight composite toe boots for electricians or durable alloy toe boots for industrial workers, we have the production capabilities to meet your exact specifications. Let us help you equip your workforce with the perfect blend of safety and comfort. Contact our team today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- Are composite toe boots more comfortable than steel toe? Discover the Benefits for Your Workday

- Why is it important to check the labels on steel cap work boots? Ensure Genuine, Certified Foot Protection

- What industries commonly require the use of steel cap work boots? Essential Guide for High-Risk Sectors

- What are the characteristics of steel toe safety boots? Maximum Protection, Key Trade-offs

- Do steel toe boots increase the risk of trips and falls? How Quality Design Enhances Stability

- What are the pros and cons of steel toe work boots? A Guide to Maximum Protection vs. Comfort

- What factors should be considered when choosing between steel and composite toe caps? Ensure Maximum Safety and Comfort

- Why are steel toe shoes important in workplaces with heavy items? Essential Protection for Industrial Safety