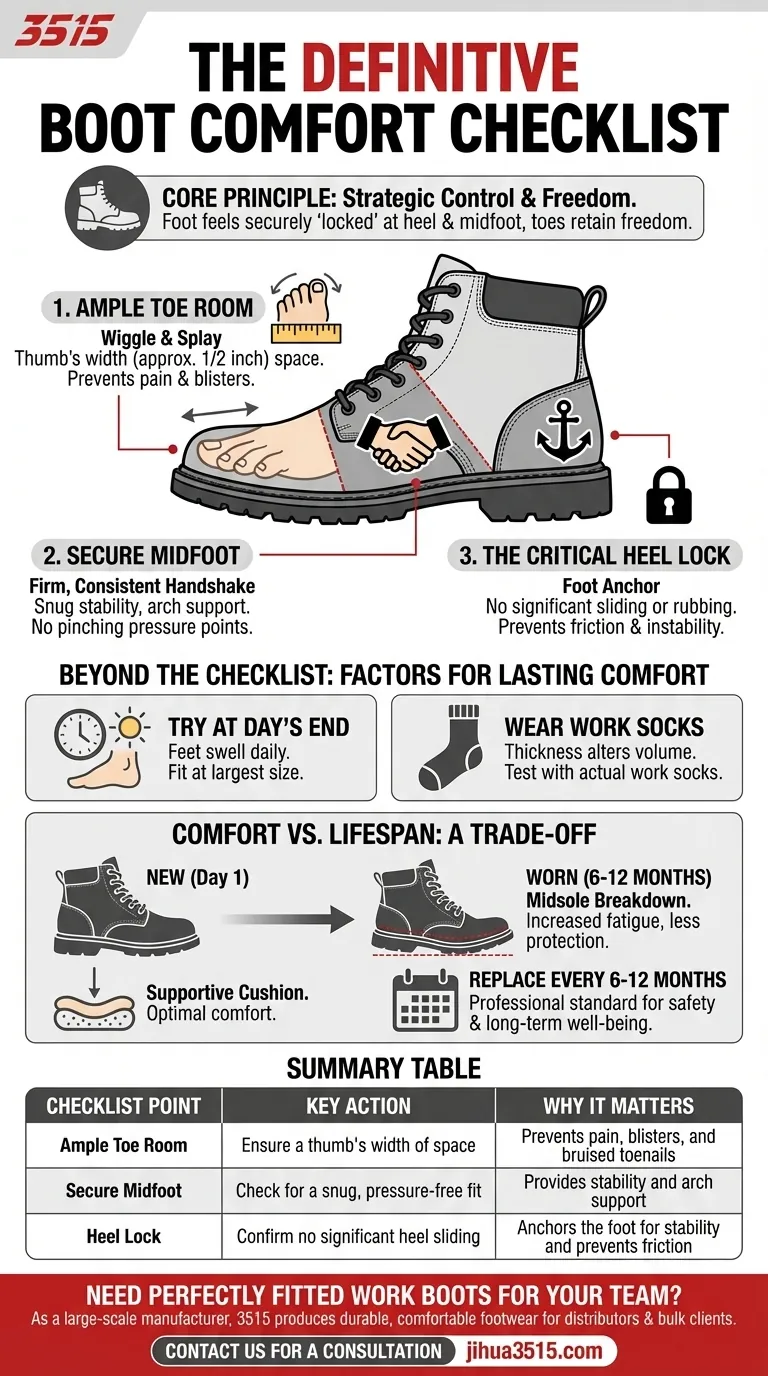

The definitive boot comfort checklist is a simple, three-point assessment that professionals use to verify a proper fit. It involves confirming the big toe has adequate wiggle room, the heel remains locked in place without sliding, and the midsection of the foot is held snugly without uncomfortable pressure points. Mastering this check is the first step to preventing foot fatigue and injury on the job.

The core principle of a proper boot fit is not about overall tightness, but about strategic control. Your foot should feel securely "locked" at the heel and midfoot, while your toes retain the freedom to move and splay naturally throughout the day.

The Three-Point Fit Assessment

A truly comfortable and effective boot is built on three pillars of fit. Evaluating each one separately, in the correct order, provides a clear and reliable assessment of any boot you try on.

1. Ample Toe Room

Your toes need space to splay and move, especially as your feet swell slightly during a long day of work.

A constrained toebox is a primary cause of pain, blisters, and even bruised toenails. You should have about a half-inch, or a thumb's width, of space between your longest toe and the end of the boot's toe cap.

2. A Secure Midfoot

The boot should feel like a firm, consistent handshake around the middle of your foot and over your instep.

This snug connection is what provides stability and arch support. You should feel contact all around, but without any specific "hot spots" or pinching pressure that could cause pain later.

3. The Critical Heel Lock

This is the most important element of the fit. Your heel is the anchor for your foot, and if it moves, you lose stability and create friction.

When you walk, your heel should remain firmly seated in the boot's heel cup. A very slight amount of initial lift (less than a quarter-inch) can be acceptable in stiff new leather boots, but any significant sliding or rubbing is a clear sign of a poor fit.

Beyond the Checklist: Factors for Lasting Comfort

A perfect fit in the store can fail in the field if you don't account for real-world conditions. These factors are just as important as the three-point check itself.

Try Boots at the End of the Day

Your feet naturally swell throughout the day from standing and walking.

Trying on boots in the afternoon or evening ensures you are fitting them to your foot at its largest size, preventing a fit that becomes too tight after a few hours of work.

Wear Your Work Socks

The thickness of your socks can dramatically alter the volume inside your boot, changing the fit entirely.

Always test new boots while wearing the exact type and thickness of sock you use for work. A boot that fits perfectly with a thin athletic sock may be painfully tight with a thick wool or cushioned work sock.

Understanding the Trade-offs: Comfort vs. Lifespan

The initial comfort of a boot is only part of the equation. As a tool, a boot's materials will degrade over time, directly impacting its comfort and support.

Comfort is Not Permanent

The foam and support structures in a boot's midsole compress with every step. Over time, this supportive cushion breaks down, leading to increased fatigue and impact on your joints.

Even if the exterior looks fine, a boot with a worn-out midsole is no longer providing adequate protection.

The Replacement Cadence

The advice to replace boots every six to twelve months is a professional standard, especially for those in demanding environments. This is not a sales tactic; it is a long-term comfort and safety strategy.

Continuing to wear a boot after its internal support has failed can lead to chronic pain and potential injury. Consider the boot's lifespan as a crucial part of its performance specifications.

Making the Right Choice for Your Goal

Use these guidelines to translate your fit assessment into a final decision based on your specific needs.

- If your primary focus is immediate, all-day comfort: Prioritize a perfect three-point fit out of the box and ensure there are absolutely no pressure points or heel slip.

- If your primary focus is durability in a harsh environment: Accept that a stiffer boot may require a break-in period, but never compromise on having adequate toe room and a secure heel lock from day one.

Ultimately, a properly fitted boot is the most fundamental piece of equipment for ensuring your daily performance and long-term well-being.

Summary Table:

| Checklist Point | Key Action | Why It Matters |

|---|---|---|

| Ample Toe Room | Ensure a thumb's width of space | Prevents pain, blisters, and bruised toenails |

| Secure Midfoot | Check for a snug, pressure-free fit | Provides stability and arch support |

| Heel Lock | Confirm no significant heel sliding | Anchors the foot for stability and prevents friction |

Need Perfectly Fitted Work Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and comfortable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety and work boots, designed with the precise fit and long-term comfort your customers demand.

Let us help you equip your workforce with superior footwear.

Contact us today for a consultation to discuss your specific needs and volume requirements.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Durable 6-Inch Work Boots | Custom & Private Label Manufacturer

People Also Ask

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job