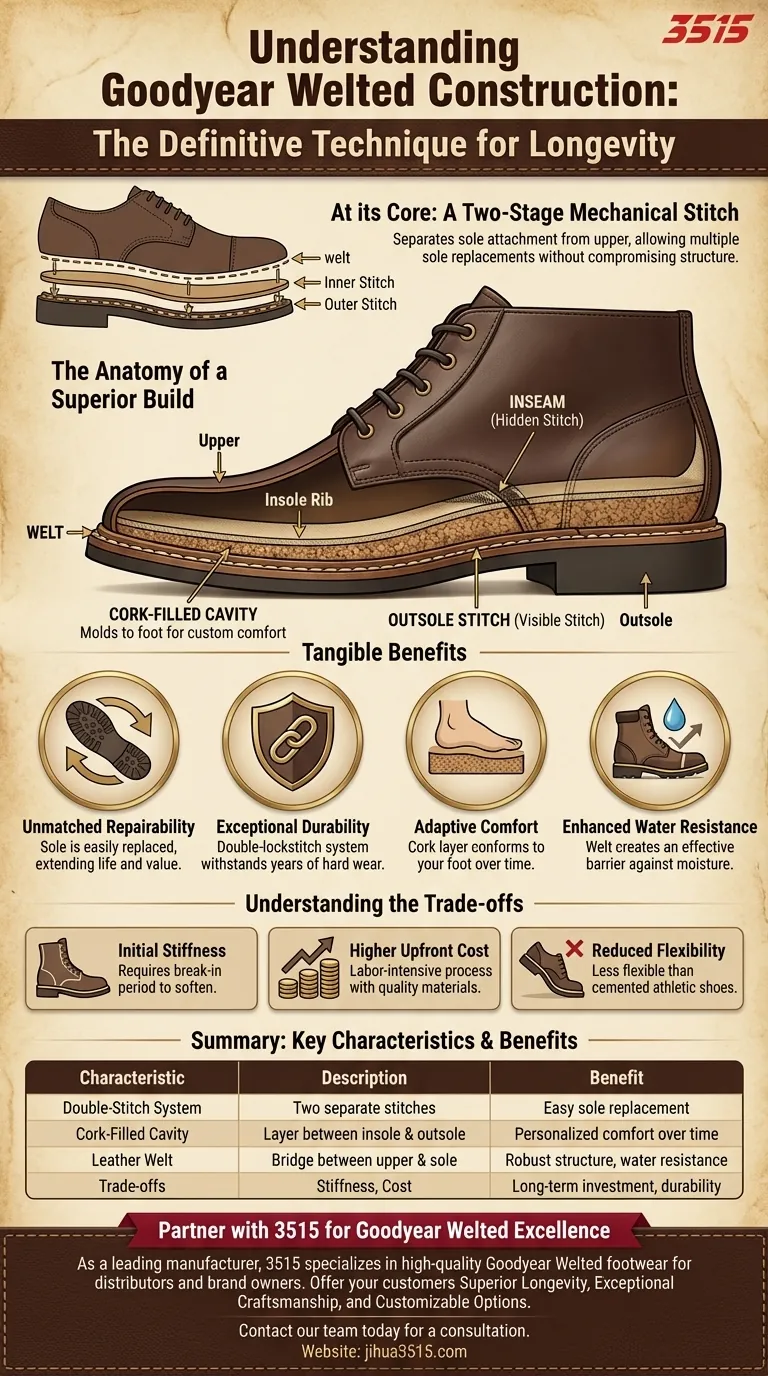

At its core, Goodyear Welted construction is a time-honored shoemaking technique that mechanically stitches the shoe together in two distinct stages. First, an inner stitch binds the upper, the lining, and a leather strip called a "welt" to a rib on the insole. Then, a separate, visible outer stitch attaches this welt to the outsole, creating an exceptionally durable and repairable shoe.

The crucial insight is that Goodyear Welt construction separates the sole attachment from the upper. This two-level system means the sole can be replaced multiple times without compromising the shoe's core structure, making it the definitive choice for footwear designed for longevity.

The Anatomy of a Superior Build

To understand why this method is so highly regarded, it's essential to look at its key components and how they interact. This isn't just about stitching; it's about a complete structural system.

The Welt: The Critical Link

The welt is a dedicated strip of leather that runs along the perimeter of the outsole. It acts as a crucial intermediary, connecting the upper part of the shoe to the sole.

This design is the foundation of the shoe's strength and repairability. The stitches holding the sole in place do not pass through into the main body of the shoe.

The Double-Stitch System

Goodyear welting is defined by its use of two independent lockstitches.

- The Inseam: This is a hidden stitch that fastens the insole, upper, and welt together.

- The Outsole Stitch: This is the visible stitch that joins the welt to the outsole.

Because these stitches are separate, a cobbler can easily cut the outsole stitch and attach a new sole without ever disturbing the upper.

The Cork-Filled Cavity

The process of attaching the welt creates a cavity between the insole and the outsole. This space is filled with a layer of granulated cork.

Over time, with the heat and pressure of your foot, this cork layer compresses and molds to the unique shape of your foot, creating a personalized footbed.

The Tangible Benefits of This Method

The complex construction of a Goodyear welted shoe directly translates into several practical advantages for the wearer.

Unmatched Repairability

This is the primary benefit. When the sole wears out, it can be removed and replaced. This dramatically extends the life of the footwear, turning an expensive purchase into a long-term investment.

Exceptional Durability

The double-stitching, often using a lockstitch that won't unravel if one part breaks, creates a robust and resilient shoe. This construction is built to withstand years of hard wear, far surpassing modern cemented or glued methods.

Adaptive Comfort

While not as soft out-of-the-box as a sneaker, the cork footbed provides superior long-term comfort. After a break-in period, the shoe essentially has a custom insole molded perfectly to your foot's contours.

Enhanced Water Resistance

The welt creates a more effective barrier between the ground and your foot. While not fully waterproof, it offers significantly more protection from moisture seeping in than simpler construction methods.

Understanding the Trade-offs

No construction method is perfect for every application. Objectivity requires acknowledging the inherent compromises of a Goodyear welt.

Initial Stiffness

The multiple layers, leather insole, and cork filling result in a shoe that is initially quite stiff. A break-in period is required for the materials to soften and conform to your foot.

Higher Upfront Cost

The Goodyear welt process is labor-intensive and requires specialized machinery and skilled artisans. This complexity, along with the quality of materials used, results in a higher initial purchase price.

Reduced Flexibility

By its very nature, this robust construction is less flexible than a lightweight, cemented shoe. While ideal for a sturdy boot or dress shoe, it is not suited for athletic footwear where maximum flexibility is key.

Making the Right Choice for Your Goal

Deciding if Goodyear welt is right for you depends entirely on your priorities for the footwear.

- If your primary focus is longevity and value over time: This construction is the best choice, as the ability to resole the shoe makes it a superior long-term investment.

- If your primary focus is out-of-the-box comfort: Be prepared for a break-in period; other constructions may feel more comfortable on the first wear but lack long-term durability.

- If your primary focus is a durable, weather-resistant work or dress shoe: Goodyear welt provides the ideal balance of strength, repairability, and protection from the elements.

Ultimately, choosing a Goodyear welted shoe is an investment in craftsmanship that pays dividends in durability and personalized comfort for years to come.

Summary Table:

| Key Characteristic | Description | Benefit |

|---|---|---|

| Double-Stitch System | Two separate stitches: one for the upper/welt, another for the welt/sole. | Allows for easy sole replacement without damaging the upper. |

| Cork-Filled Cavity | A layer of cork between the insole and outsole. | Molds to the wearer's foot for personalized comfort over time. |

| Leather Welt | A strip of leather acting as a bridge between the upper and the sole. | Creates a robust structure and enhances water resistance. |

| Trade-offs | Higher initial cost and stiffness requiring a break-in period. | An investment in long-term value and durability. |

Ready to offer your customers the unparalleled durability of Goodyear Welted footwear?

As a leading manufacturer, 3515 specializes in producing high-quality Goodyear Welted shoes and boots for distributors, brand owners, and bulk clients. We combine time-tested construction techniques with modern efficiency to deliver footwear built to last.

Partner with us to provide your customers with:

- Superior Longevity: Shoes that can be resoled repeatedly, maximizing their lifespan.

- Exceptional Craftsmanship: Meticulous attention to detail and robust construction.

- Customizable Options: A comprehensive range of styles to meet your market's needs.

Let's discuss how our manufacturing expertise can enhance your product line. Contact our team today for a consultation.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Heavy-Duty Goodyear Welted Pull-On Safety Rigger Boot

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

People Also Ask

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors