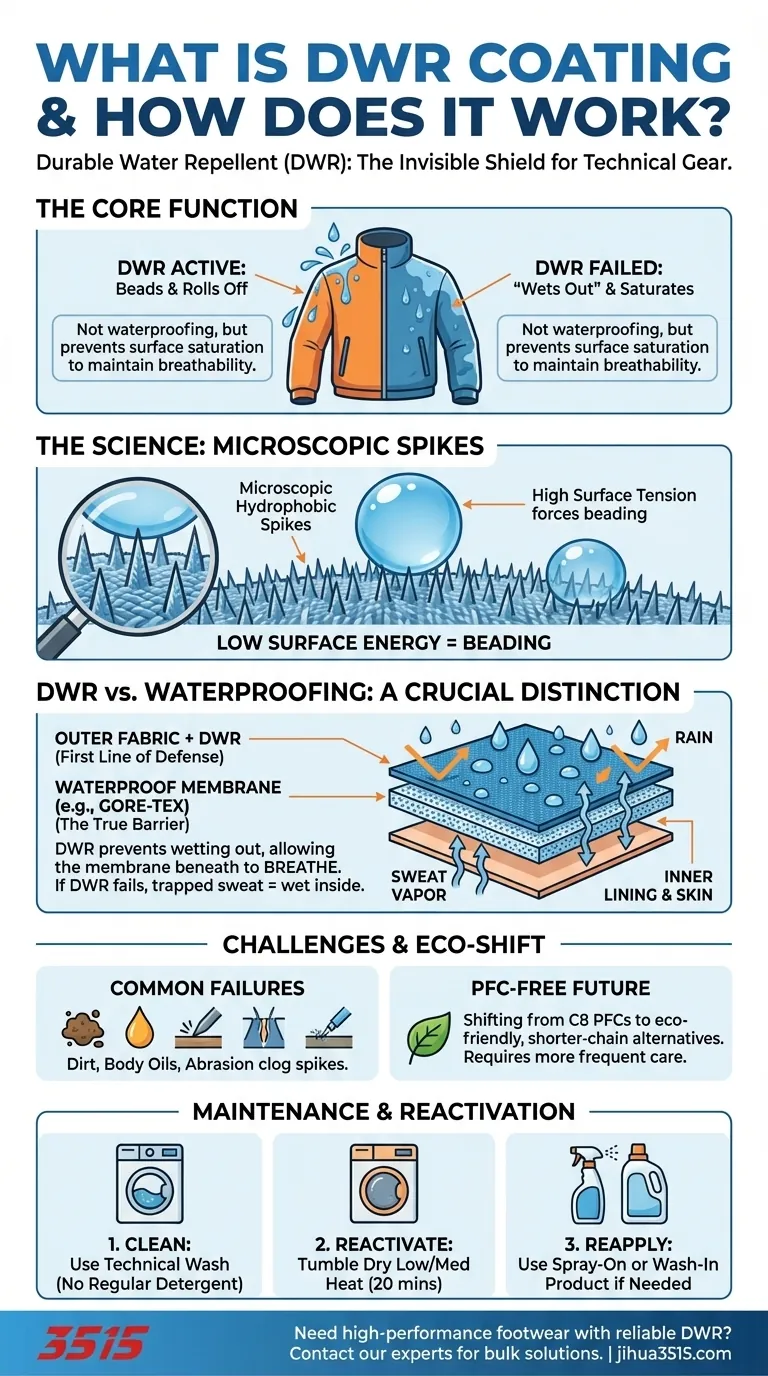

At its core, a Durable Water Repellent (DWR) coating is a chemical treatment applied to the exterior fabric of technical apparel like jackets, pants, and boots. Its purpose is not to make the item waterproof, but to cause water to form beads and roll off the surface. This prevents the outer fabric from becoming saturated with moisture, a condition known as "wetting out."

DWR is not what makes your gear waterproof; it's what allows your waterproof gear to breathe. A failed DWR coating causes the outer fabric to get waterlogged, which blocks the breathable membrane underneath and traps your sweat, making you feel wet from the inside.

How DWR Actually Works: The Science of Surface Tension

To understand DWR, you must think on a microscopic level. It's not a solid, impermeable layer like a sheet of plastic.

Creating Microscopic Spikes

A DWR finish works by creating a microscopic, spiky surface structure on the individual fibers of the fabric. These chemical "spikes" are hydrophobic, meaning they repel water.

Increasing Surface Tension

This structure drastically lowers the surface energy of the fabric. When a water droplet lands on it, the fabric's low surface energy forces the water's own high surface tension to pull the droplet into a tight, round bead.

Preventing "Wetting Out"

Because the water forms distinct beads instead of spreading out, it can't soak into the fabric's fibers. The slightest angle or movement causes these beads to roll off, keeping the face fabric dry and lightweight.

DWR vs. Waterproofing: A Crucial Distinction

Many people mistakenly believe DWR is what makes a jacket waterproof. This is a critical misunderstanding that leads to frustration when gear seems to "fail."

DWR: The First Line of Defense

DWR is the first line of defense against precipitation. It handles light rain, snow, and splashes with ease by shedding the moisture before it can be absorbed. However, under sustained, heavy rain or pressure, it can be overwhelmed.

Waterproof Membranes: The True Barrier

The actual waterproofing comes from an internal membrane or coating, such as GORE-TEX or eVent. This is a layer bonded underneath the outer fabric that contains billions of microscopic pores per square inch.

These pores are thousands of times smaller than a water droplet, making them impenetrable to outside moisture. At the same time, they are large enough for individual water vapor molecules (your sweat) to pass through from the inside out. This is what defines a material as both waterproof and breathable.

Why DWR is Essential for Breathability

This is the most important concept to grasp. If the DWR fails, the outer fabric gets saturated and "wets out." This waterlogged layer effectively clogs the microscopic pores of the waterproof membrane from the outside.

Your sweat vapor no longer has an escape route. It gets trapped inside your jacket, condenses back into liquid, and makes you feel cold, clammy, and wet—even though no external water has leaked through the membrane.

Understanding the Trade-offs and Limitations

The "Durable" in DWR is a relative term. The coating's performance will inevitably degrade over time and with use.

Common Causes of Failure

The primary enemies of a DWR finish are contaminants that cover up its microscopic structure. These include dirt, body oils, sunscreen, and detergent residue. Abrasion from backpack straps or scraping against surfaces also physically wears down the treatment.

The Environmental Shift to PFC-Free

Historically, the most effective DWR treatments used perfluorinated chemicals (PFCs), specifically long-chain C8 fluorocarbons. These were highly effective but have been phased out due to their persistence in the environment.

The industry has shifted to shorter-chain (C6) or, increasingly, PFC-free DWR treatments. While much better for the environment, these modern alternatives are generally less durable and require more frequent maintenance to maintain their performance.

How to Maintain and Reactivate Your DWR

You can often restore your gear's performance without reapplying a new coating. A DWR finish that appears to have failed is often just dirty.

Step 1: Clean Your Gear

First and foremost, wash the item according to the manufacturer's instructions. Use a technical wash specifically designed for outdoor apparel, as regular detergents can leave behind residues that attract water.

Step 2: Reactivate with Heat

Often, a simple cleaning is all that's needed. After washing, a 20-minute tumble dry on low-to-medium heat can reactivate the existing DWR treatment, causing the chemical molecules to realign and restore their water-repellency.

Step 3: Reapply When Necessary

If water still fails to bead up after a thorough wash and dry cycle, it's time to reapply the finish. You can use a variety of spray-on or wash-in DWR restoration products available at any outdoor retailer.

Making the Right Choice for Your Gear

Maintaining your DWR is simple, but it is the key to getting the performance you paid for.

- If your gear is new and starting to absorb water: Your DWR is likely just contaminated; clean it and use heat to reactivate it before buying any re-proofing products.

- If you operate in harsh, wet conditions: Proactive cleaning is your best tool for maintaining the breathability that keeps you from getting soaked by your own sweat.

- If you are buying new gear: Recognize that modern PFC-free DWR treatments are better for the environment but will likely require more frequent care to perform at their best.

Proper DWR care is the single most effective way to ensure your technical gear performs as designed, keeping you dry from both the outside and the inside.

Summary Table:

| Aspect | Key Information |

|---|---|

| Function | Repels water to prevent outer fabric from becoming saturated ("wetting out"). |

| How It Works | Creates a microscopic, hydrophobic surface on fabric fibers to make water bead and roll off. |

| Crucial Role | Prevents waterlogged fabric from blocking the breathable waterproof membrane underneath. |

| Common Causes of Failure | Dirt, oils, sunscreen, detergent residue, and abrasion. |

| Maintenance Steps | 1. Clean with technical detergent. 2. Reactivate with heat (tumble dry). 3. Reapply DWR spray/wash-in product if needed. |

Need high-performance footwear with reliable DWR coatings?

As a large-scale manufacturer, 3515 produces a comprehensive range of technical boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of waterproof and breathable footwear, built with durable finishes to withstand the elements.

Contact our experts today to discuss your footwear needs and discover how we can bring value to your product line.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- What is the OSHA standard for safety-toe boots? Ensuring Compliance and Worker Protection

- Why are safety boots with steel toes mandatory for logging? Ultimate Protection Against Heavy Impact Hazards

- Why do operations involving heavy fruit bunches and 'gancu' require anti-smash and anti-puncture safety boots?

- What are heavy duty work boots designed for? Maximum Protection for Hazardous Work Environments

- What role do industrial safety shoes with steel toes or composite protective layers play in high-risk manufacturing?