At its core, Aerogel is a synthetic porous material derived from a gel, in which the liquid component has been replaced with a gas without significant collapse of the gel's solid structure. The most common type is made from silica, resulting in a solid that is over 99% air, making it the world's lightest solid material and one of its most effective insulators.

Aerogel's remarkable insulating ability isn't about the material itself, but about its structure. It works by using an extremely fine, solid lattice to trap air in pores so small that they prevent heat from moving through conduction, convection, or radiation.

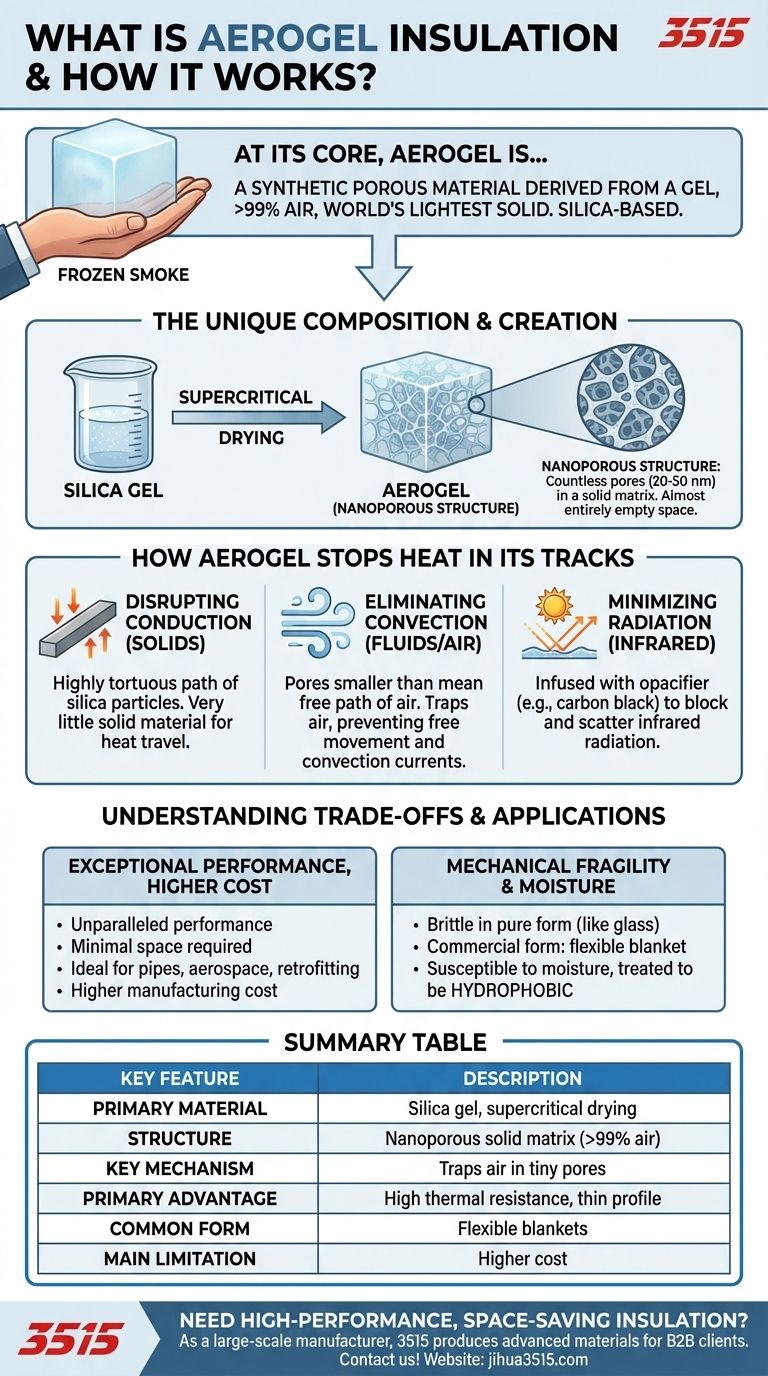

The Unique Composition of Aerogel

To understand how aerogel works, you must first understand how it's made. It's a feat of material science that transforms a common substance into something extraordinary.

From Gel to "Frozen Smoke"

The creation process starts with a silica gel, similar in consistency to gelatin. This gel's liquid component is then carefully removed through a process called supercritical drying.

This advanced technique extracts the liquid without the surface tension that would normally cause the delicate solid structure to collapse, preserving its intricate, web-like framework. The result is a solid material with extremely low density, often called "frozen smoke" for its translucent appearance.

The Nanoporous Structure

The defining feature of aerogel is its nanoporous structure. It is a solid matrix riddled with countless microscopic pores, typically between 20 and 50 nanometers in diameter.

This means the final product is almost entirely empty space. This structure is the fundamental reason for aerogel's incredible thermal properties.

How Aerogel Stops Heat in Its Tracks

Heat moves in three ways: conduction (through solids), convection (through fluids like air), and radiation. Aerogel’s structure is uniquely engineered to disrupt all three of these pathways effectively.

Disrupting Conduction

While aerogel is a solid, its structure is a highly tortuous path of silica particles. There is very little solid material for heat to travel through, making direct thermal conduction extremely inefficient.

Eliminating Convection

This is aerogel's primary advantage. Convection occurs when air molecules move and transfer energy. However, the pores in aerogel are smaller than the mean free path of air molecules at standard pressure.

This means air molecules don't have enough room to move freely and form the convection currents that transfer heat. The air is essentially trapped in place, rendering it unable to act as a heat transfer medium.

Minimizing Radiation

To further boost performance, especially at higher temperatures, many aerogel insulation products are infused with an opacifier, such as carbon black. This material effectively blocks and scatters infrared radiation, the third form of heat transfer.

Understanding the Trade-offs

While its performance is unparalleled, aerogel is not a universal solution. Understanding its limitations is critical for making an informed decision.

Exceptional Performance, Higher Cost

The complex and energy-intensive manufacturing process makes aerogel significantly more expensive than traditional insulation materials like fiberglass or foam. Its use is typically justified where performance, not budget, is the primary constraint.

Mechanical Fragility

In its pure, monolithic form, aerogel is very brittle and can shatter like glass. To overcome this, commercial aerogel insulation is typically manufactured in the form of a flexible blanket, where the aerogel is embedded within a non-woven fiber batting for durability.

Susceptibility to Moisture

If aerogel's nanopores become filled with liquid, its insulating properties are dramatically reduced because liquid is a much better conductor of heat than trapped air. For this reason, most aerogel products are treated to be hydrophobic (water-repellent).

Making the Right Choice for Your Goal

Aerogel insulation is a specialized tool. Its application depends entirely on the specific problem you need to solve.

- If your primary focus is maximum thermal performance in a minimal space: Aerogel is the ideal choice for applications like insulating pipes, retrofitting historic buildings, or in aerospace and industrial settings where every millimeter counts.

- If your primary focus is cost-effective insulation for standard construction: Traditional materials like fiberglass, mineral wool, or foam board offer sufficient performance for a fraction of the cost where space is not a major constraint.

Ultimately, understanding aerogel's unique structure is the key to leveraging its unparalleled thermal performance precisely where it can have the greatest impact.

Summary Table:

| Key Feature | Description |

|---|---|

| Primary Material | Silica gel, processed via supercritical drying |

| Structure | Nanoporous solid matrix (>99% air) |

| Key Mechanism | Traps air in pores smaller than the mean free path of air molecules |

| Primary Advantage | Extremely high thermal resistance in a very thin profile |

| Common Form | Flexible blankets with fiber reinforcement for durability |

| Main Limitation | Higher cost compared to traditional insulation materials |

Need high-performance, space-saving insulation solutions for your projects?

As a large-scale manufacturer, 3515 produces a comprehensive range of advanced materials for distributors, brand owners, and bulk clients. Our production capabilities can meet the demanding requirements of industries where thermal efficiency is critical.

Let us help you integrate cutting-edge solutions like aerogel into your product lines or projects. Contact our expert team today to discuss how we can deliver superior value and performance for your specific needs!

Visual Guide

Related Products

People Also Ask

- How do broad-square toe cowboy boots differ from square toe boots? Find Your Perfect Fit for Maximum Comfort

- Why should you try on shoes with the socks you plan to wear regularly? Ensure a Perfect, Pain-Free Fit

- What role do high-grade protective gloves play in cleaning foundry castings? Ensure Safety & Precision in Grinding

- Why is the training of high-skilled industrial workers vital for high-end footwear? Mastering Quality & Precision

- Under what conditions does Goretex breathe effectively? Maximize Performance in Cold, Dry Climates

- Why is physical signal synchronization preferred for dual-robot outsole handling? Achieve Perfect Material Integrity

- What type of wax is recommended for leather boots? Protect & Nourish with Natural Blends

- What are the key principles for dressing well in winter cycling conditions? Master the Layering System