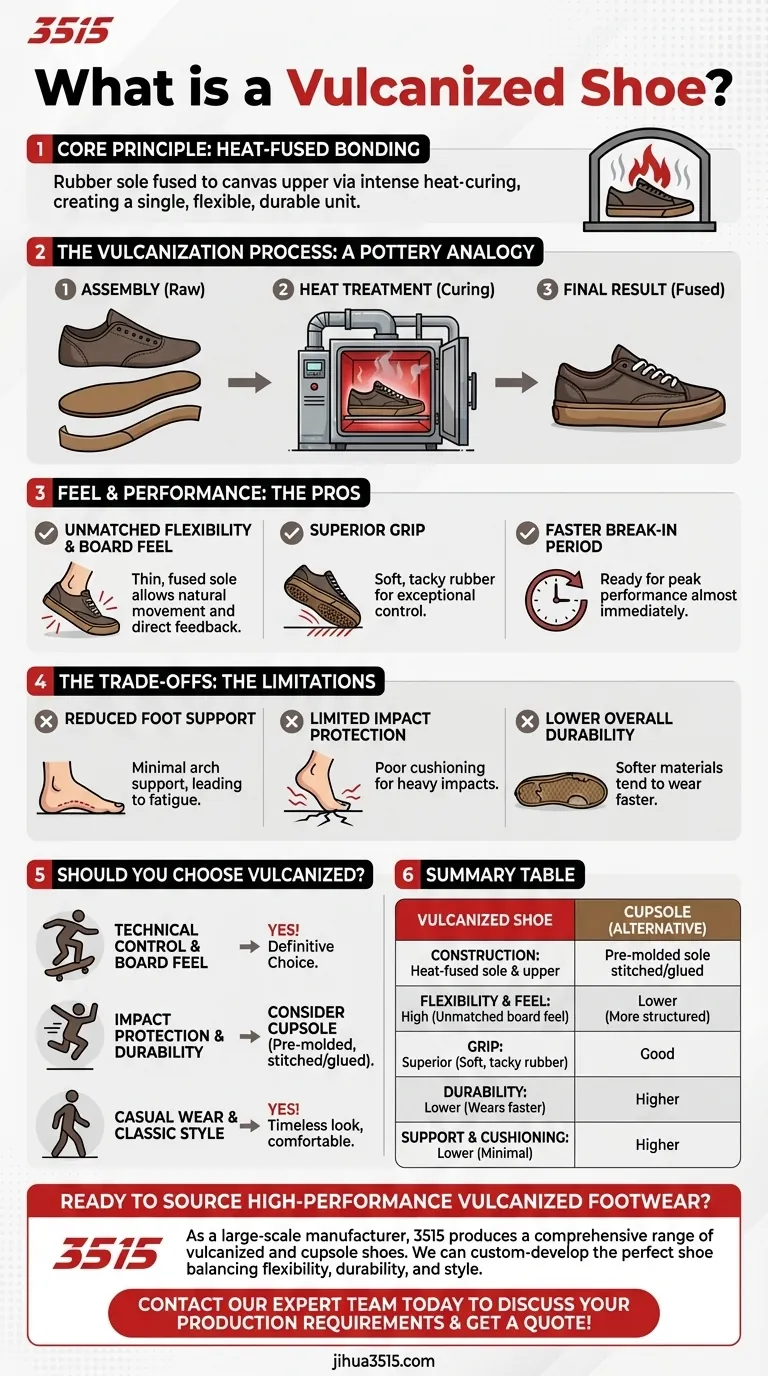

In short, a vulcanized shoe is one where the rubber sole is attached to the canvas or fabric upper through a heat-curing process. Instead of being stitched or glued with traditional cold cement, the components are essentially baked together, creating a single, bonded unit that is both flexible and durable.

The core principle of a vulcanized shoe is its construction: heat is used to fuse the rubber sole directly to the upper. This process results in unparalleled flexibility and board feel, but it comes with a trade-off in foot support and long-term durability.

The Vulcanization Process: A Simple Analogy

Think of building a vulcanized shoe like firing a piece of pottery in a kiln. You assemble the raw, pliable pieces first and then use intense heat to transform them into a single, finished product.

### Assembling the Raw Components

First, the shoe's fabric upper (the part that covers your foot) is sewn and shaped. Separately, the rubber is mixed, calendared into sheets, and cut to form the outsole. A rubber strip, known as foxing tape, is then wrapped around the shoe where the upper meets the sole.

### The Heat Treatment (Curing)

The assembled shoe is placed into a specialized oven or autoclave. The high heat initiates a chemical reaction in the rubber, causing it to harden, become more elastic, and permanently bond to the fabric upper and foxing tape.

### The Final Result

This process creates a shoe that feels like a single, integrated piece. The sole is characteristically soft and gummy, providing a distinct feel that differs significantly from other shoe construction methods.

What This Means for Feel and Performance

The way a vulcanized shoe is made has a direct and significant impact on how it performs, particularly for activities like skateboarding.

### Unmatched Flexibility and Board Feel

Because the sole is thin and fused directly to the upper without thick, rigid layers, the shoe is incredibly flexible right out of the box. This allows your foot to move naturally and provides a high degree of sensitivity, letting you feel the texture and contour of your skateboard or the ground beneath you.

### Superior Grip

The vulcanization process creates a softer, tackier rubber sole. This results in exceptional grip, which is crucial for maintaining control and stability.

### Faster Break-in Period

The inherent flexibility of vulcanized construction means there is almost no break-in period. The shoes are comfortable and ready for peak performance almost immediately.

Understanding the Trade-offs

While vulcanized shoes offer clear advantages in feel and grip, their construction method also introduces specific limitations. The main alternative is the cupsole, where the sole is a pre-molded rubber "cup" that is stitched and glued to the upper, offering a different set of characteristics.

### Reduced Foot Support

The same thin, flexible sole that provides great board feel offers minimal structure and arch support. This can lead to foot fatigue during long sessions.

### Limited Impact Protection

There is very little cushioning between your foot and the ground. While this is great for control, it provides poor protection from heavy impacts, such as landing tricks from a significant height.

### Lower Overall Durability

The soft rubber and single-layer foxing tape tend to wear out faster than the more robust construction of a cupsole, especially when subjected to the high abrasion of skateboarding.

Should You Choose a Vulcanized Shoe?

The right choice depends entirely on your priorities. By understanding the inherent strengths and weaknesses, you can select the shoe that best aligns with your needs.

- If your primary focus is technical control and board feel: A vulcanized shoe is the definitive choice for its flexibility and direct feedback.

- If your primary focus is impact protection and durability: You should consider a cupsole shoe, which offers superior cushioning and a longer lifespan for high-impact activities.

- If your primary focus is casual wear and classic style: Vulcanized shoes offer a timeless look and are often more affordable and comfortable for everyday use.

Ultimately, understanding shoe construction empowers you to choose your gear based on performance needs, not just aesthetics.

Summary Table:

| Aspect | Vulcanized Shoe | Alternative (Cupsole) |

|---|---|---|

| Construction | Heat-fused sole & upper | Pre-molded sole stitched/glued |

| Flexibility & Feel | High (unmatched board feel) | Lower (more structured) |

| Grip | Superior (soft, tacky rubber) | Good |

| Durability | Lower (softer rubber wears faster) | Higher |

| Support & Cushioning | Lower (minimal arch/impact support) | Higher |

| Best For | Technical control, casual wear | High-impact activities, durability |

Ready to source high-performance vulcanized footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of vulcanized and cupsole shoes for distributors, brand owners, and bulk clients. We can help you select or custom-develop the perfect shoe for your target market's needs, balancing flexibility, durability, and style.

Contact our expert team today to discuss your production requirements and get a quote!

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

People Also Ask

- What are rubber soled shoes? The Ultimate Guide to Durable, All-Weather Footwear

- What makes natural rubber provide excellent traction and grip? Unlocking Superior Performance with Molecular Science

- Which type of sole is better for premium sneakers and why? The Definitive Guide to Rubber Outsoles

- What is vulcanized rubber and why is it used in products? The Key to Durable, Flexible Footwear

- What makes rubber sole shoes an economical and practical choice? Unmatched Durability & All-Weather Value