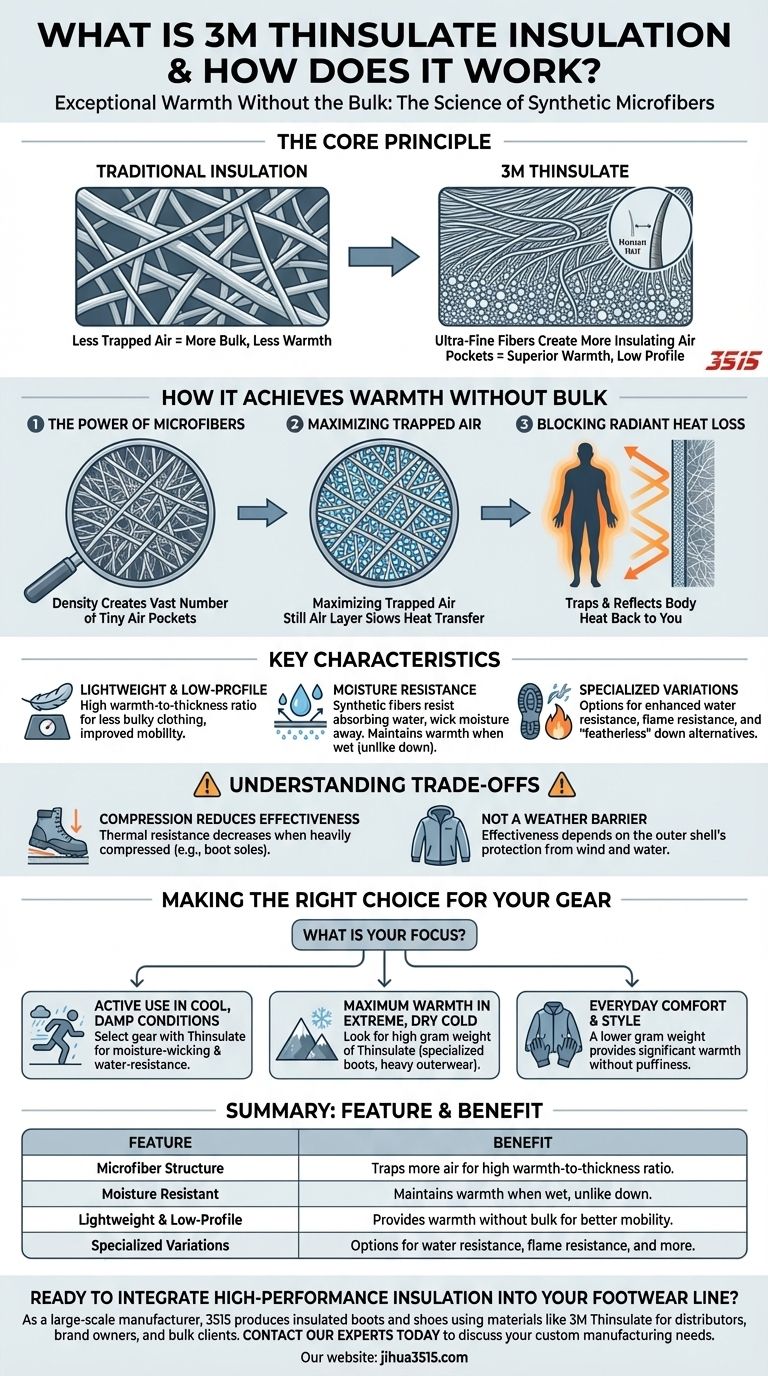

At its core, 3M Thinsulate is a brand of synthetic insulation known for providing exceptional warmth without the bulk of traditional insulating materials. It is crafted from extremely fine synthetic microfibers that are significantly thinner than human hair. This unique structure allows it to trap and hold body heat with remarkable efficiency while remaining lightweight and low-profile.

The fundamental principle behind Thinsulate is not the material itself, but the air it traps. Its ultra-fine fibers create more insulating air pockets in less space, delivering warmth that rivals thicker, heavier materials.

How Thinsulate Achieves Warmth Without Bulk

The effectiveness of any insulation is determined by how well it can trap still air. Thinsulate is engineered to maximize this principle in a minimal amount of space.

The Power of Microfibers

The fibers used in Thinsulate are incredibly fine. This density of fibers creates a vast number of tiny air pockets within the material's structure.

Maximizing Trapped Air

It is the air trapped between these fibers that does the real work of insulating. This layer of still air acts as a barrier, slowing the transfer of heat from your body to the colder outside environment.

Blocking Radiant Heat Loss

By creating this dense web of air pockets, Thinsulate effectively traps the radiant heat your body naturally produces, reflecting it back to you and keeping you warm.

Key Characteristics of Thinsulate

Beyond its primary function, Thinsulate offers several properties that make it a preferred choice in a wide range of apparel and gear, from boots to jackets.

Lightweight and Low-Profile

Its primary advantage is its high warmth-to-thickness ratio. This allows for the design of less bulky clothing that still offers excellent thermal protection, improving mobility and comfort.

Moisture Resistance

As a synthetic material, Thinsulate fibers resist absorbing water. They also help wick moisture away from the body, allowing it to evaporate and keeping you dry from the inside. This is a critical advantage over natural down, which loses its insulating power when wet.

Specialized Variations

3M produces different types of Thinsulate to meet specific needs. These include versions with enhanced water resistance, flame resistance for workwear, and "featherless" alternatives that mimic the loft and feel of natural down.

Understanding the Trade-offs

No material is perfect for every situation. Being an effective advisor means acknowledging the context where Thinsulate performs best and where its limitations lie.

Compression Reduces Effectiveness

Like all insulation that relies on loft (trapped air), Thinsulate's thermal resistance decreases when it is heavily compressed. This is an important factor in applications like the soles of boots, where body weight can flatten the fibers.

It Is Not a Weather Barrier

Thinsulate is the thermal engine, not the entire vehicle. Its effectiveness depends on the garment's outer shell, which must provide protection from wind and water to allow the insulation to function properly.

Making the Right Choice for Your Gear

Choosing apparel with Thinsulate requires matching the type and amount of insulation to your specific activity and environment.

- If your primary focus is active use in cool, damp conditions: Select gear with Thinsulate, as its moisture-wicking and water-resistant properties will keep you warmer than down if you sweat or encounter precipitation.

- If your primary focus is maximum warmth in extreme, dry cold: Look for garments with a high gram weight of Thinsulate, often found in specialized boots and heavy-duty outerwear.

- If your primary focus is everyday comfort and style: A lower gram weight of Thinsulate provides a significant boost in warmth for casual jackets and gloves without adding puffiness or bulk.

Ultimately, understanding that Thinsulate works by trapping air in a thin, lightweight structure empowers you to select gear that delivers targeted warmth without weighing you down.

Summary Table:

| Feature | Benefit |

|---|---|

| Microfiber Structure | Traps more air for high warmth-to-thickness ratio. |

| Moisture Resistant | Maintains warmth when wet, unlike down. |

| Lightweight & Low-Profile | Provides warmth without bulk for better mobility. |

| Specialized Variations | Options for water resistance, flame resistance, and more. |

Ready to integrate high-performance insulation into your footwear line?

As a large-scale manufacturer, 3515 produces a comprehensive range of insulated boots and shoes for distributors, brand owners, and bulk clients. We leverage materials like 3M Thinsulate to create gear that offers superior warmth, comfort, and durability for your customers.

Contact our experts today to discuss your custom manufacturing needs.

Visual Guide

Related Products

- Premium Insulated Safety Boots and Shoes for Wholesale & Bulk Orders

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

People Also Ask

- What are the benefits of using winter cycling shoes compared to overshoes? Superior Warmth & Convenience

- What are the comprehensive production capabilities of a large-scale footwear manufacturer serving distributors and brand owners? Unlock Bulk Production Excellence

- What hygiene and warmth benefits do shoes provide indoors? Discover the Full Range of Indoor Footwear Advantages

- How does a Manufacturing Execution System (MES) support footwear production compliance? Ensure Full Traceability

- What are the manufacturing advantages of using Polyurethane (PU)? Explore High-Performance Footwear Solutions

- Why buy winter cycling shoes one or two sizes larger? The Key to Warmth & Circulation

- What advantages do smart insoles offer for HAR? Capture Precision Gait Data for Safety and Rehab

- Why are miniature thin flexible pressure sensors necessary for wearable insoles? Optimize Gait Data & Biomechanics