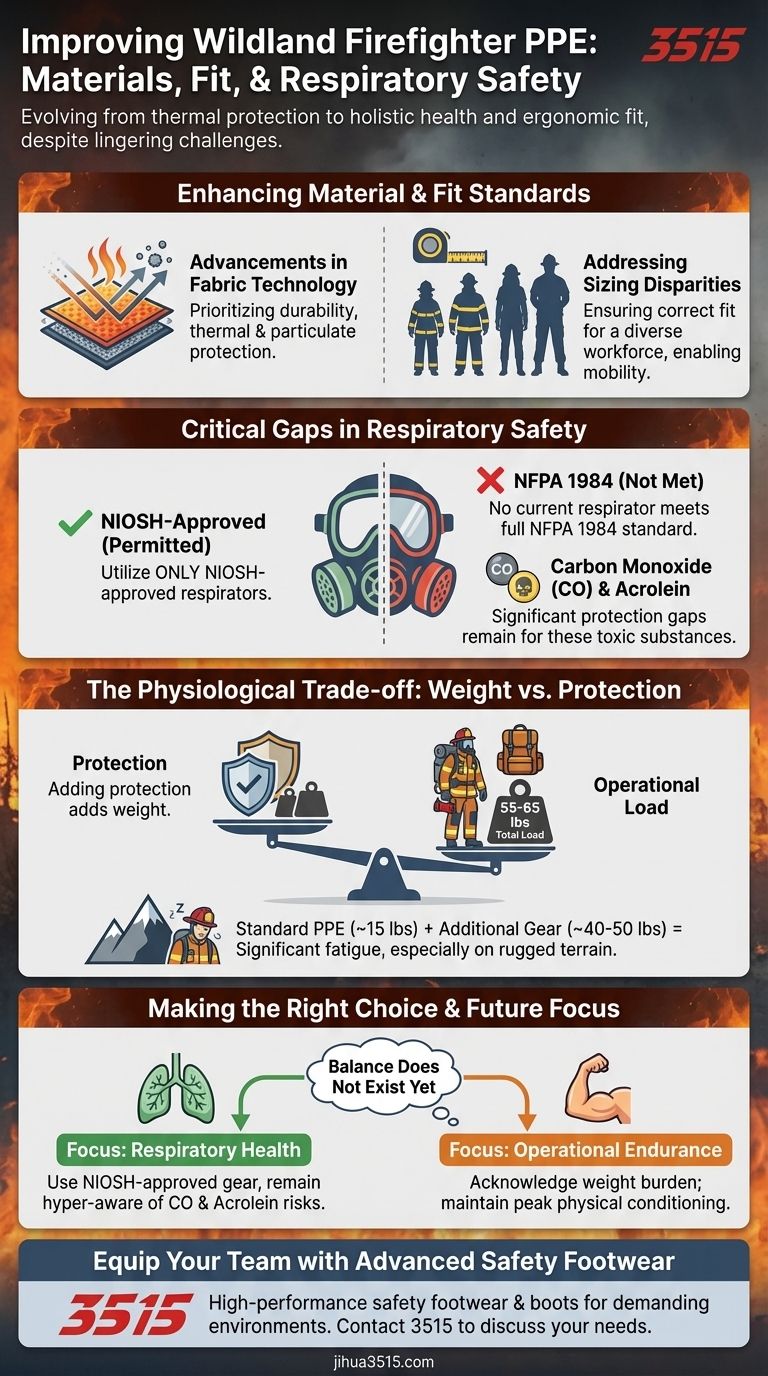

Current improvements to wildland firefighter PPE focus heavily on updating fabric performance, establishing rigorous particulate protection standards, and correcting historical sizing disparities. Simultaneously, the industry is striving to develop respiratory protection that balances high-level filtration with the operational reality of working in extreme conditions.

The evolution of wildland PPE is shifting from simple thermal protection to a holistic focus on long-term health and ergonomic fit. However, significant gaps remain between current technology and the ideal safety standards for respiratory health and load management.

Enhancing Material and Fit Standards

Advancements in Fabric Technology

Recent efforts have prioritized updating fabric performance standards. The goal is to improve durability and thermal protection while addressing the critical need for particulate protection.

Addressing Sizing Disparities

Manufacturers and standards organizations are actively working to address sizing disparities. This initiative ensures that PPE functions correctly for a diverse workforce, as ill-fitting gear compromises both safety and mobility.

Critical Gaps in Respiratory Safety

The Certification Standard

Currently, only NIOSH-approved respirators are permitted for use in suppression activities. However, it is crucial to note that no current respirator on the market meets all requirements set by NFPA 1984.

Protection Limitations

While approved respirators address many hazards, they do not provide total protection. Significant gaps remain regarding specific toxic substances, particularly acrolein and carbon monoxide.

Non-Certified Risks

Despite the limitations of approved gear, non-certified respirators are explicitly not recommended. The focus remains on utilizing NIOSH-approved equipment while development continues on models that meet the full NFPA 1984 standard.

The Physiological Trade-off: Weight vs. Protection

The Cumulative Load

Adding protection invariably adds weight. Standard PPE currently weighs up to 15 lbs.

The Total Operational Burden

When combined with necessary additional gear, a firefighter carries an extra 40 to 50 lbs. This results in a total additional load of approximately 55 to 65 lbs.

Impact on Fatigue

This weight significantly contributes to fatigue, especially when operating on steep or rugged terrain. Because the gear burden is high, physical training remains an essential job component to ensure operational effectiveness.

Making the Right Choice for Your Safety

While technology is advancing, the perfect balance of protection and weight does not yet exist. You must work within current limitations.

- If your primary focus is respiratory health: Utilize only NIOSH-approved respirators, but remain hyper-aware that you are still vulnerable to carbon monoxide and acrolein.

- If your primary focus is operational endurance: Acknowledge that improved PPE does not yet equal lighter gear; maintain peak physical conditioning to counteract the significant weight of standard equipment.

Stay informed on evolving standards, as the gap between current gear and NFPA requirements is an active area of development.

Summary Table:

| Improvement Area | Key Focus | Current Status & Challenges |

|---|---|---|

| Material Technology | Enhanced durability, thermal & particulate protection | Standards evolving; fabrics improving |

| Fit & Sizing | Correcting disparities for diverse workforce | Active work by manufacturers & standards bodies |

| Respiratory Protection | NIOSH-approved respirators; meeting NFPA 1984 | Gaps remain for carbon monoxide & acrolein |

| Weight & Ergonomics | Balancing added protection with operational load | Standard PPE adds ~15 lbs; total gear burden is 55-65 lbs, impacting fatigue |

Equip Your Team with Advanced, Durable Safety Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance safety footwear and boots for distributors, brand owners, and bulk clients. We understand the critical need for gear that supports endurance and protection in the most demanding environments.

Our production capabilities encompass all types of safety shoes and boots designed for durability and comfort, helping to mitigate the physical burden on firefighters and other first responders.

Ready to enhance your safety gear supply? Contact 3515 today to discuss your specific needs and discover how our manufacturing expertise can provide reliable, high-quality footwear for your teams.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- When should someone consult a podiatrist about foot pain? Don't Ignore These Warning Signs

- How does negative electronic Word of Mouth (eWOM) impact brand equity? Protect Your Footwear Brand's Digital Reputation

- What is the function of a two-roll open mill? Enhancing CNT/NR Composite Mixing and Dispersion

- What organization sets national standards for workplace safety in the U.S.? OSHA's Role Explained

- What is the function of multi-axis IMUs in footwear testing? Enhancing Gait Analysis and Stability Metrics

- What are over-the-counter orthotic inserts used for? Relieve Common Foot Pain and Discomfort

- What are the key protective features of motorcycle-specific boots? Essential Safety for Every Rider

- What are some style features available in tall riding boots? From Field to Dress Boots