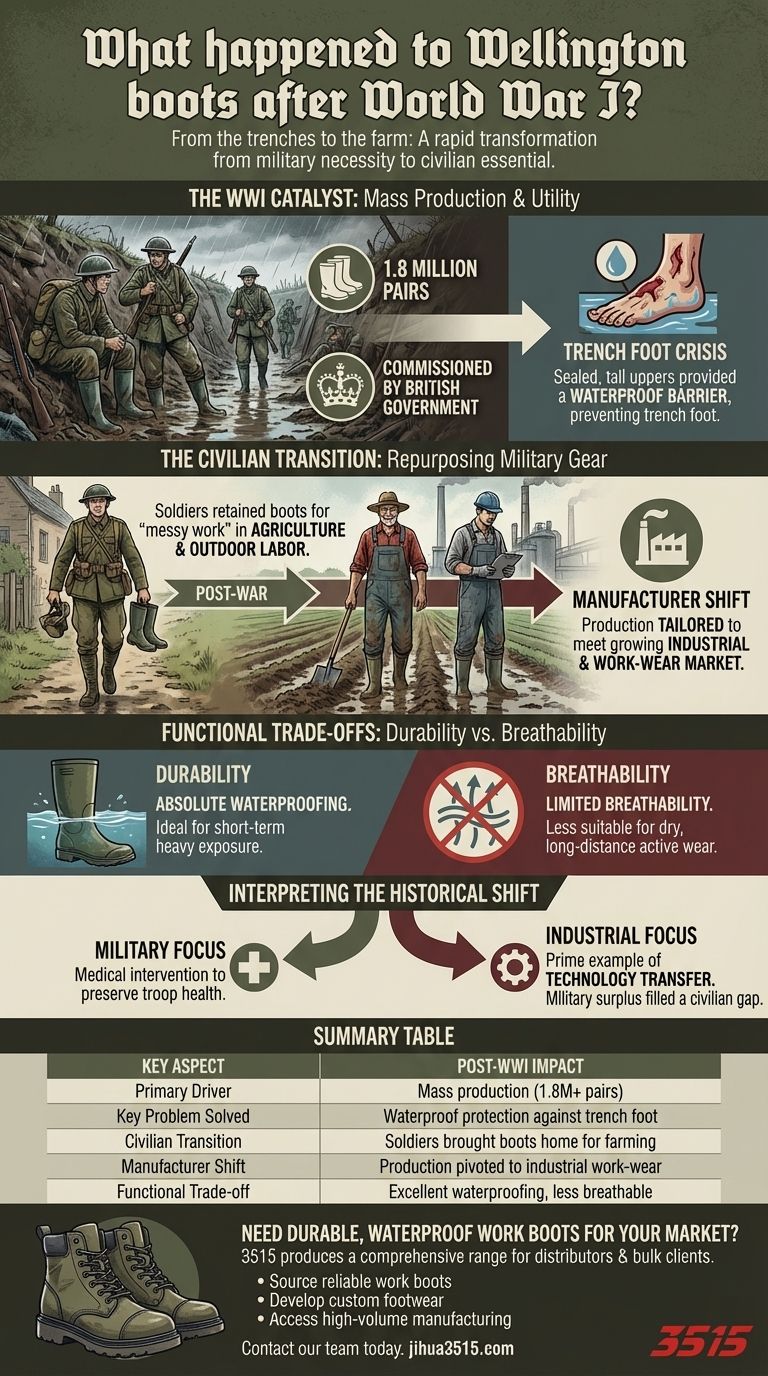

From the trenches to the farm. Following World War I, the Wellington boot underwent a rapid transformation from military necessity to civilian essential. Soldiers returning to civilian life retained their boots for agricultural and outdoor labor, valuing the waterproof rubber for "messy work." This organic shift in usage compelled manufacturers to pivot, tailoring the boots throughout the 20th century to serve a growing industrial and work-wear market.

The Core Transformation: The Wellington boot did not disappear after the armistice; it was repurposed. The sheer volume of production (1.8 million pairs) combined with the boot's proven ability to prevent trench foot created a ready-made solution for the muddy realities of civilian agriculture and industry.

The Catalyst: Mass Production and Utility

Meeting the Demand of War

During World War I, the British government commissioned the production of rubber Wellington boots on a massive scale.

Over 1.8 million pairs were manufactured to meet the specific needs of the army.

Solving the Trench Foot Crisis

The primary driver for this production was the condition of the battlefields in Europe.

Trenches were frequently flooded and muddy, leading to a prevalence of trench foot among the troops.

The Wellington’s sealed, tall uppers provided a waterproof barrier, keeping soldiers' feet clean and dry in environments where standard leather boots failed.

The Civilian Transition

Repurposing Military Gear

When the war ended, soldiers did not leave this utility behind on the battlefield.

Returning to civilian jobs involving outdoor or messy work, veterans continued to wear their issued Wellingtons.

The boot's effectiveness in the trenches translated perfectly to the mud and wet conditions of farming and labor.

A Shift in Manufacturing Focus

Manufacturers observed this sustained usage and adjusted their strategies accordingly.

Throughout the 20th century, production was tailored to meet increasing demand in the general work boot market.

The design evolved from a strictly military specification to a staple of the industrial working class.

Understanding the Functional Trade-offs

Specialized for "Messy Work"

The post-war adoption of the Wellington was driven by necessity, not aesthetics or general comfort.

References highlight that the boots were adopted specifically for "messy work," indicating they were a specialized tool rather than general-purpose footwear.

Durability vs. Breathability

While the references focus on water protection, the reliance on rubber for preventing trench foot highlights a specific trade-off.

The material offers absolute waterproofing but lacks the breathability of other materials, making it ideal for short-term heavy exposure but potentially less suitable for dry, long-distance active wear.

Interpreting the Historical Shift

To understand the legacy of the Wellington boot, you must look at how military supply chains influence civilian markets.

- If your primary focus is military history: Recognize that the boot was primarily a medical intervention designed to preserve troop health against trench foot through mass production.

- If your primary focus is industrial history: View the Wellington as a prime example of technology transfer, where military surplus and design durability filled a gap in the civilian agricultural sector.

The Wellington boot survives today because it solved a fundamental problem—keeping feet dry in extreme conditions—that was as relevant on the farm as it was in the trench.

Summary Table:

| Key Aspect | Post-WWI Impact on Wellington Boots |

|---|---|

| Primary Driver | Mass production for WWI (1.8M+ pairs) created a large surplus. |

| Key Problem Solved | Waterproof protection against trench foot and muddy conditions. |

| Civilian Transition | Soldiers brought boots home for farming and outdoor labor. |

| Manufacturer Shift | Production pivoted to meet growing industrial work-wear demand. |

| Functional Trade-off | Excellent waterproofing, but less breathable than other materials. |

Need Durable, Waterproof Work Boots for Your Market?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including modern iterations of durable, functional footwear inspired by classics like the Wellington boot.

We can help you:

- Source reliable work boots built for tough conditions.

- Develop custom footwear tailored to your specific market needs.

- Access high-volume manufacturing with consistent quality.

Let's discuss how we can supply the right footwear for your customers.

Contact our team today to request a quote

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What precautions should be taken when waterproofing boots? Protect Your Investment and Stay Safe

- How should work boots fit properly? A Guide to All-Day Comfort and Safety

- Why is it important for women to wear work boots specifically designed for them? The Critical Role of Anatomical Fit

- What are the requirements for impact resistance in safety toe boots? Ensure Maximum Protection for Your Workforce

- What are the disadvantages of composite toe boots? Key Limitations for Your Safety

- What are the common types of toe protection in work boots? Choose the Right Safety Toe for Your Job

- Which type of boot is more breathable: waterproof or water-resistant? Find Your Perfect Fit.

- What daily maintenance steps should be taken for work boots? A Simple 3-Step Routine for Longevity