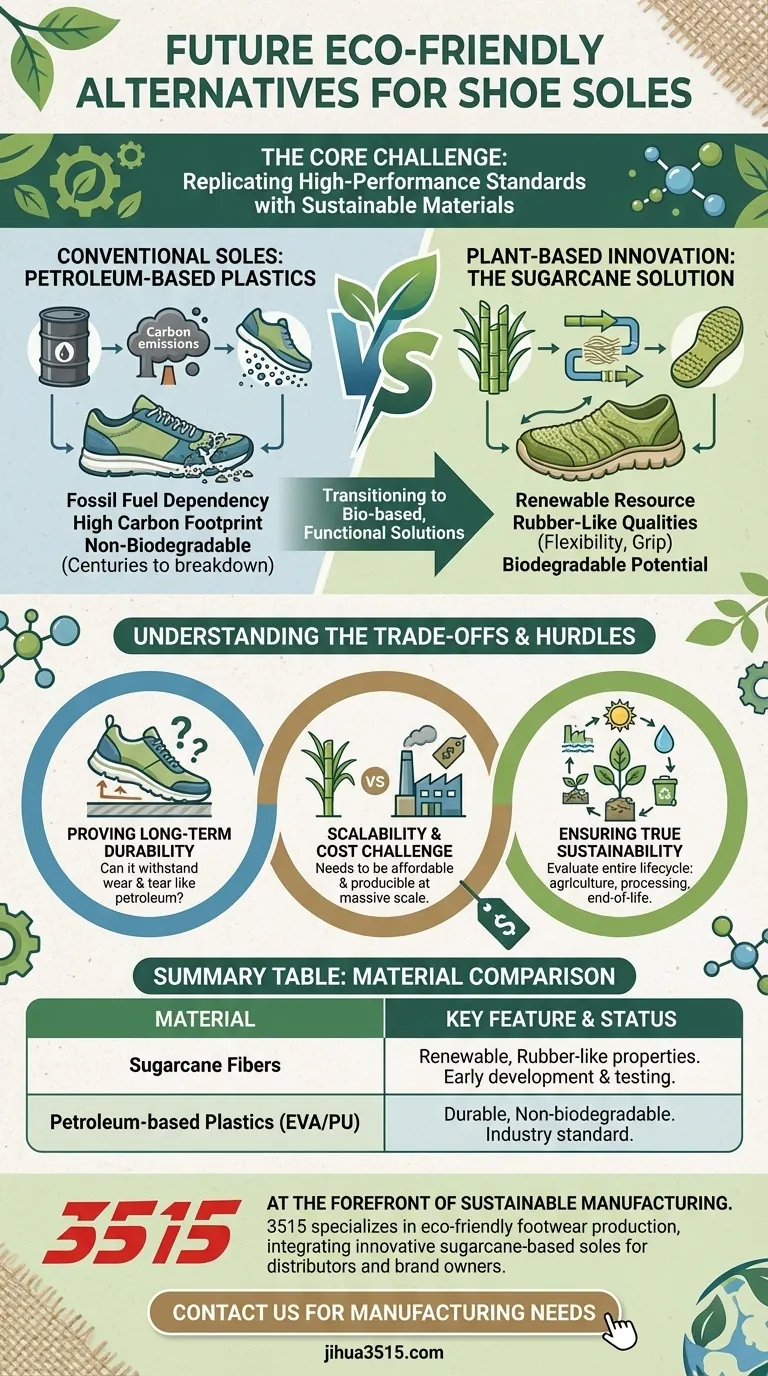

At the forefront of eco-friendly footwear, the most significant exploration for future shoe soles centers on plant-based materials designed to replace petroleum plastics. Key experiments are underway to develop soles from sugarcane fibers, a renewable resource engineered to replicate the essential rubber-like qualities needed for performance and comfort. This innovation marks a critical shift away from fossil fuels in the footwear industry.

The core challenge is not just finding a sustainable material, but engineering it to meet the high-performance standards of traditional, petroleum-based rubber. The current focus on sugarcane represents a move towards bio-based solutions that can be both renewable and functional.

The Problem with Conventional Shoe Soles

The soles of most modern shoes are a hidden environmental liability. They are typically made from materials that are energy-intensive to produce and persist in the environment for centuries after disposal.

The Reliance on Petroleum Plastics

Traditional soles are often made from EVA (ethylene-vinyl acetate) or polyurethane, both of which are plastics derived from petroleum. This ties a fundamental component of footwear directly to the fossil fuel industry.

This dependency means shoe production contributes to carbon emissions and relies on a finite, non-renewable resource.

Durability vs. Decomposition

Conventional sole materials are engineered for durability, which is excellent for performance but terrible for the environment. These plastics do not biodegrade, instead breaking down into harmful microplastics over hundreds of years.

This creates a fundamental conflict: the very quality that makes a shoe last is what makes it a long-term pollutant.

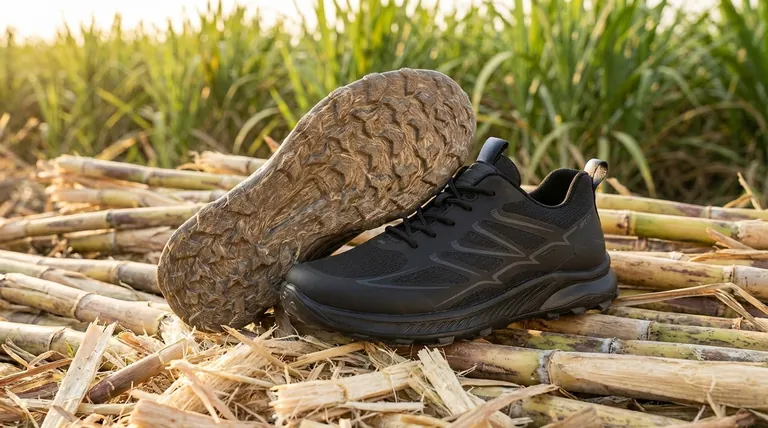

Plant-Based Innovation: The Sugarcane Solution

To solve this problem, researchers are turning to the plant kingdom. The goal is to find a renewable resource that can be processed into a high-performance material.

The Leading Contender: Sugarcane Fibers

Sugarcane is emerging as a primary candidate. It is a fast-growing, renewable crop that can be processed into fibers for creating a durable, flexible base material.

This approach aims to create a "drop-in" replacement—a material that can be used in existing manufacturing processes with minimal changes.

Replicating Rubber-Like Qualities

The critical test for any new sole material is its performance. The sugarcane-based alternative is being specifically developed to mimic the properties of rubber, including flexibility, shock absorption, and grip.

Success depends on achieving this performance without compromising the material's sustainable advantages.

From Early Stages to Manufacturing

While the technology is promising, it is still in the early stages of development. The primary focus is on refining the material composition and proving its viability through testing.

The next step, which researchers hope to take soon, is scaling up production for commercial manufacturing.

Understanding the Trade-offs and Hurdles

Shifting to a new material is never simple. While the environmental benefits are clear, there are significant practical challenges to overcome before plant-based soles become the industry standard.

Proving Long-Term Durability

The biggest question is whether a new biomaterial can withstand the same wear and tear as its petroleum-based predecessor. Extensive testing is required to ensure it won't degrade prematurely during use.

The Challenge of Scalability and Cost

Currently, petroleum-based plastics benefit from decades of industrial optimization, making them cheap and easy to produce at a massive scale.

A new material like sugarcane fiber will need to prove it can be produced affordably and in sufficient quantities to meet global demand.

Ensuring True Sustainability

It is also crucial to evaluate the entire lifecycle of the new material. This includes the agricultural impact of growing sugarcane, the energy used in processing, and its true end-of-life biodegradability.

How to Approach This Innovation

Understanding the goal behind these material shifts allows you to make more informed choices as a consumer or industry professional.

- If your primary focus is supporting cutting-edge sustainability: Keep an eye out for brands launching pilot programs or limited-edition shoes featuring these new biomaterials.

- If your primary focus is proven performance and durability: It may be wise to wait until these materials have been on the market long enough to be validated by real-world user reviews.

The journey toward sustainable footwear is about replacing finite resources with renewable ones without sacrificing the performance we depend on.

Summary Table:

| Material | Key Feature | Current Status |

|---|---|---|

| Sugarcane Fibers | Renewable, rubber-like properties | Early development & testing |

| Petroleum-based Plastics (EVA/PU) | Durable, non-biodegradable | Industry standard |

As a large-scale manufacturer, 3515 is at the forefront of sustainable footwear production. We specialize in creating a comprehensive range of eco-friendly shoes and boots for distributors, brand owners, and bulk clients. Our advanced production capabilities allow us to integrate innovative materials like sugarcane-based soles into high-performance footwear. If you're looking to lead the market with sustainable, durable products, contact us today to discuss your manufacturing needs.

Visual Guide

Related Products

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

- Durable Moc-Toe Wedge Work Boots | Wholesale Manufacturing for Brands

- Premium KPU Injection Athletic Style Safety Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- What is the relationship between footwear design and the effectiveness of biomechanical alignment? Maximize Stability

- How do safety harnesses assist in high-intensity treadmill testing? Ensure Data Validity for High-Performance Footwear

- What role do professional training shoes play during HIIT for adolescent athletes? Stability and Injury Prevention

- How do professional athletic shoes contribute to safety on flexible balance boards? Enhance Stability & Prevent Slips

- How do specialized training shoes and sneakers support high-intensity training? Maximize Performance & Stability