The most critical features in non-slip restaurant shoes are a high-traction rubber sole with a specialized tread pattern, comprehensive cushioning and arch support for long hours of standing, and a durable, water-resistant upper construction that is easy to clean. These elements work together to ensure both immediate safety from slips and long-term protection from fatigue and foot pain.

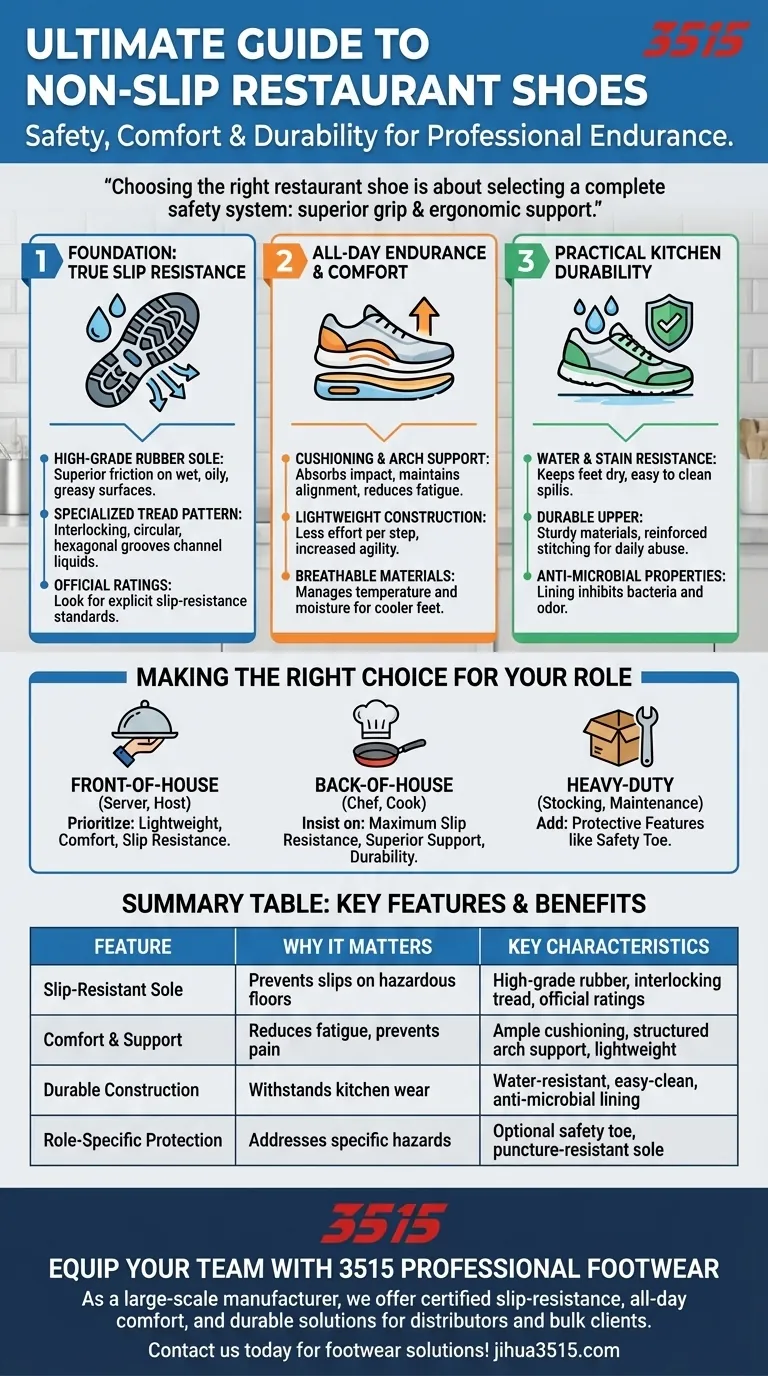

Choosing the right restaurant shoe is not about a single feature, but about selecting a complete safety system. The best shoe balances superior grip on hazardous surfaces with the ergonomic support needed to endure the physical demands of a full shift.

The Foundation: Unpacking True Slip Resistance

A "non-slip" label is the starting point, not the final word. True performance comes from the specific design and materials of the shoe's outsole, which is the part that makes direct contact with the floor.

The Sole Material

The industry standard for high-performance slip-resistant soles is high-grade rubber or a specialized synthetic equivalent. This material provides superior friction and grip on wet, oily, or greasy surfaces commonly found in kitchens and dining areas.

The Tread Pattern

The design of the tread is just as important as the material. Look for interlocking patterns, circular grooves, or hexagonal shapes. These patterns are engineered to channel liquids like water and grease out from under the shoe, maximizing the surface area of the sole that maintains contact with the floor.

Look for Official Ratings

To ensure you are getting a shoe that has been properly tested, look for explicit labeling that indicates it meets specific safety standards. While standards vary, a shoe that has been officially rated for slip resistance provides a higher level of assurance.

Beyond Grip: Features for All-Day Endurance

Avoiding a slip is the immediate goal, but preventing chronic pain and fatigue is essential for a long career. This is where comfort and support features become critical.

Cushioning and Arch Support

Constant standing on hard floors puts immense pressure on your feet, knees, and back. A quality shoe must have ample cushioning in the midsole to absorb impact and structured arch support to maintain proper foot alignment, reducing strain over an 8- to 12-hour shift.

Lightweight Construction

A heavy, clunky shoe will drain your energy. A lightweight design reduces the effort required for each step, which adds up to significantly less fatigue by the end of the day and allows for more agile movement in a fast-paced environment.

Breathable Materials

An active kitchen environment is hot. Shoes with breathable lining materials help to manage temperature and moisture, keeping your feet cooler and drier, which is essential for comfort and preventing issues like blisters and odor.

Practical Demands of the Kitchen Environment

A restaurant shoe is a piece of professional equipment that must withstand daily abuse. Durability and ease of maintenance are non-negotiable.

Water and Stain Resistance

Spills are inevitable. The shoe's upper material, whether leather or a synthetic, should be water-resistant to keep your feet dry and stain-resistant to make cleanup quick and simple.

Durable Upper Construction

The shoe must be built to last. Look for sturdy materials and reinforced stitching that can handle the scrapes, scuffs, and chemical exposure common in a kitchen setting.

Anti-Microbial Properties

Many quality work shoes include an anti-microbial lining. This feature helps to inhibit the growth of odor-causing bacteria, keeping your shoes fresher for longer.

Understanding the Trade-offs and Additional Protections

Not all restaurant jobs have the same hazards. Understanding the specific needs of your role will help you choose the appropriate level of protection.

Comfort vs. Maximum Protection

There is often a trade-off between a highly protective shoe and a lightweight, flexible one. A shoe with a steel toe cap will offer more impact protection but will also be heavier and potentially less comfortable for a server who is constantly moving.

When to Consider Toe Protection

If your role involves moving heavy objects like kegs, stock pots, or equipment, a shoe with a steel or composite safety toe is a wise investment. This feature protects your feet from crushing injuries.

Specialized Hazard Ratings

For roles in large-scale or industrial kitchens, you may need to consider other safety features. These can include puncture-resistant soles or protection against electrical hazards (marked ESD), depending on the specific environment.

Making the Right Choice for Your Role

Select your shoe based on the primary demands of your specific job.

- If your primary focus is front-of-house (server, host): Prioritize a lightweight, comfortable design with excellent cushioning and certified slip resistance.

- If your primary focus is back-of-house (chef, line cook): Insist on maximum slip resistance, superior arch support, and durable, water-resistant construction.

- If your primary focus is heavy-duty work (stocking, maintenance): Add protective features like a safety toe to the core requirements of grip and support.

Ultimately, the right shoe is a critical investment in your safety, comfort, and professional endurance.

Summary Table:

| Feature | Why It Matters | Key Characteristics |

|---|---|---|

| Slip-Resistant Sole | Prevents slips on wet, oily floors | High-grade rubber, interlocking tread pattern, official ratings |

| Comfort & Support | Reduces fatigue during long shifts | Ample cushioning, structured arch support, lightweight design |

| Durable Construction | Withstands kitchen wear and tear | Water-resistant, easy-to-clean upper, anti-microbial lining |

| Role-Specific Protection | Addresses specific job hazards | Optional steel toe, puncture-resistant sole for heavy-duty roles |

Ready to equip your team with superior non-slip footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of professional footwear designed for the demanding restaurant environment. We offer:

- Certified Slip-Resistance: Our shoes feature high-traction rubber soles with specialized tread patterns to keep your staff safe.

- All-Day Comfort: Built with advanced cushioning and arch support to reduce fatigue and improve productivity.

- Durable & Easy to Clean: Constructed with water-resistant materials for long-lasting performance in any kitchen.

We provide reliable, high-quality footwear solutions for distributors, brand owners, and bulk clients seeking to enhance safety and comfort for their teams.

Contact us today to discuss your needs and discover how 3515 can be your trusted footwear partner!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- How do non-slip shoes differ from slip-resistant shoes? Uncover the Key to Workplace Safety

- Why should industrial footwear programs include regular replacement of slip resistant shoes? Ensure Consistent Safety

- What factors affect the lifespan of slip-resistant shoes? The truth about safety and wear.

- What is the purpose of water-resistant non-slip shoes? Achieve Dual-Protection for Workplace Safety

- What are the essential qualities of shoes for servers and waiters? Invest in Safety, Comfort & Durability

- What role does slip resistance play in firefighting boots? Ensuring Stability and Safety in Hazardous Conditions

- Who typically needs slip-resistant shoes? Secure Your Stride in Hazardous Environments

- Why is a high-performance anti-slip outsole essential for single-leg exoskeleton users? Ensure Stability and Safety