At its core, choosing the right work boot requires you to evaluate features across three critical categories: safety, environment, and fit. The most important features to consider are the type of toe protection, the slip-resistance of the outsole, the boot's overall construction, and its suitability for your specific work environment, including waterproofing or insulation.

Your work boot is not just footwear; it is a critical piece of Personal Protective Equipment (PPE). The "best" boot is the one designed specifically to mitigate the hazards and meet the physical demands of your job.

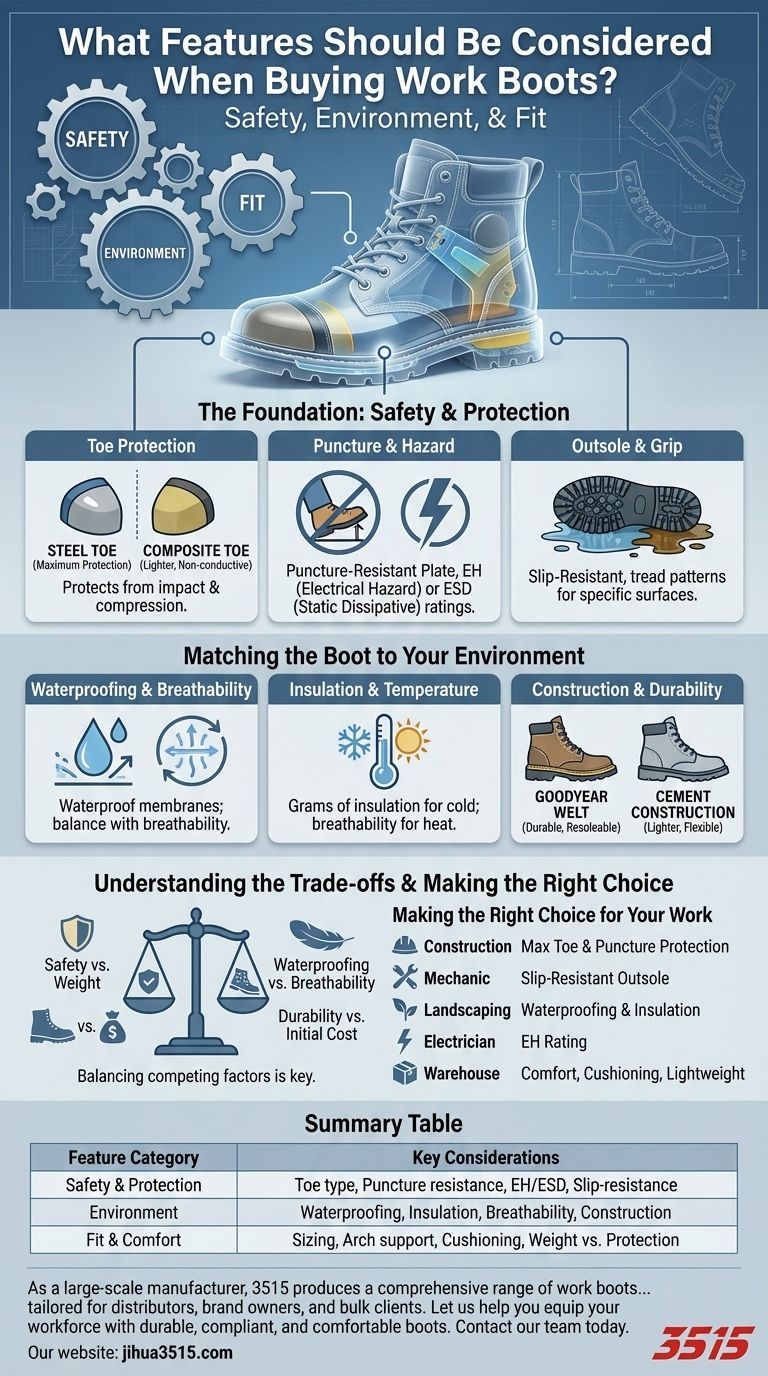

The Foundation: Safety and Protection

A work boot's primary function is to protect you from jobsite hazards. Understanding the specific types of protection is the first step in making an informed choice.

Understanding Toe Protection

Your boots must have certified toe protection if you work around heavy objects. This feature is designed to protect your toes from compression and impact.

The most common type is the steel toe, known for maximum protection. Other options include composite toes (made of non-metal materials like Kevlar or carbon fiber), which are lighter and don't conduct electricity or cold.

Beyond the Toe: Puncture and Hazard Resistance

Many jobs involve sharp hazards on the ground, like nails or scrap metal. A puncture-resistant plate, often made of steel or flexible composite material, is built into the sole to protect the bottom of your foot.

For those working around electricity, boots with an Electrical Hazard (EH) rating provide insulation against accidental contact with live circuits. Conversely, Static Dissipative (ESD) boots reduce the buildup of static electricity.

The Critical Role of the Outsole

The outsole is your boot's connection to the ground. A slip-resistant sole is absolutely essential for anyone working on surfaces that may become wet, oily, or otherwise slick.

Look for tread patterns and rubber compounds specifically designed for the surfaces you encounter most often.

Matching the Boot to Your Environment

Beyond immediate impact or electrical hazards, your daily work environment dictates the features you'll need for comfort and long-term durability.

Waterproofing and Breathability

If you work outdoors or in wet conditions, a waterproof boot is essential. These often use a waterproof membrane liner to keep your feet dry from the outside.

Remember that true waterproofing can limit a boot's ability to breathe, which might be a concern in very hot climates.

Insulation for Temperature Control

For work in cold environments, insulated boots are a necessity. Insulation is typically measured in grams—the higher the number, the warmer the boot.

The Importance of Construction

How a boot is made determines its durability and flexibility. Goodyear welt construction involves stitching the upper to the sole, making the boot extremely durable and easy to resole.

Cement construction is a more common method where the sole is glued to the upper. This creates a lighter, more flexible boot but is generally less durable.

Understanding the Trade-offs

Selecting the right boot always involves balancing competing factors. Being aware of these trade-offs is key to avoiding buyer's remorse.

Safety vs. Weight

Maximum protection often means more weight. Steel toes and heavy-duty puncture plates offer superior safety but can contribute to fatigue over a long day compared to lighter composite materials.

Waterproofing vs. Breathability

A fully waterproof boot is excellent at keeping water out, but it can also trap sweat inside. In hot, dry conditions, a more breathable, non-waterproof boot will be far more comfortable.

Durability vs. Initial Cost

Boots with high-end construction like a Goodyear welt cost more upfront. However, their durability and ability to be resoled can make them a more economical choice over the long term compared to cheaper, cemented boots that must be replaced entirely.

Making the Right Choice for Your Work

Evaluate your daily tasks and hazards to select the features that matter most.

- If your primary focus is construction or heavy industry: Prioritize maximum toe and puncture protection (like steel toes and plates) and a durable construction method.

- If your primary focus is as a mechanic or on slick floors: A certified slip-resistant outsole is your most critical feature.

- If your primary focus is landscaping or outdoor utility work: Waterproofing and appropriate insulation for your climate are non-negotiable.

- If your primary focus is as an electrician or utility worker: You must select a boot with a certified Electrical Hazard (EH) rating.

- If your primary focus is long hours on your feet in a warehouse: Emphasize a comfortable fit, proper cushioning, and a lightweight design to minimize fatigue.

Ultimately, investing in the right work boot is a direct investment in your own safety and daily well-being.

Summary Table:

| Feature Category | Key Considerations |

|---|---|

| Safety & Protection | Toe type (steel/composite), puncture resistance, EH/ESD rating, slip-resistant outsole |

| Environment | Waterproofing, insulation (grams), breathability, construction type (Goodyear welt/cement) |

| Fit & Comfort | Proper sizing, arch support, cushioning, weight vs. protection balance |

As a large-scale manufacturer, 3515 produces a comprehensive range of work boots tailored for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear designed to meet the specific hazards and demands of your industry—from steel-toe boots for construction to EH-rated footwear for electricians.

Let us help you equip your workforce with durable, compliant, and comfortable boots. Contact our team today to discuss your specific needs and receive a customized solution.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What types of workers might need insulated work boots? Essential Footwear for Cold Environments

- Why is it worth investing in a high-quality pair of moc toe boots? For Long-Term Value & Durability

- What features should cowboy boots have for rugged, physical labor jobs? Essential Safety & Durability Guide

- What factors should be considered when choosing work boots? Prioritize Safety, Fit, and Durability

- How can you ensure a comfortable fit when selecting oilfield work boots? A Guide to All-Day Comfort & Safety

- How can new work boots be broken in? A Step-by-Step Guide to a Pain-Free Fit

- What should be considered when choosing boots for riding and hiking? Balancing Safety, Comfort & Durability

- Which professions benefit most from 90-degree heel work boots? Achieve Unmatched Stability on Ladders and Uneven Terrain