When buying oil-resistant safety boots, the most critical factors to consider are the sole's material and design for slip resistance, the type of toe protection required for your work environment, and construction features that ensure both durability and all-day comfort. These elements work together to protect you from specific workplace hazards while minimizing physical fatigue.

The term "oil-resistant" goes beyond just preventing slips; it signifies that the boot's core materials, especially the sole, will not degrade, swell, or become brittle when exposed to oils and chemicals. Choosing the right boot means matching its specific material and safety features to the unique demands of your job.

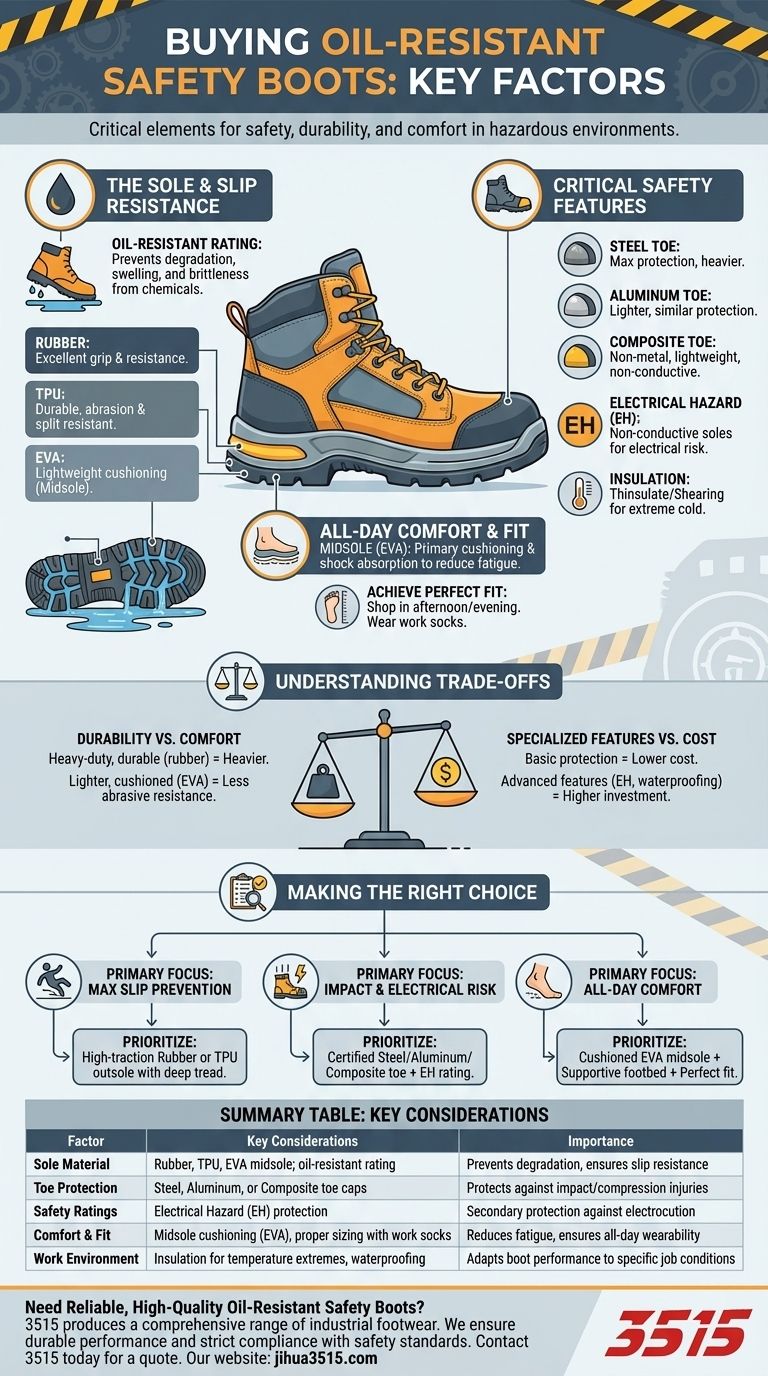

The Foundation: The Sole and Slip Resistance

The performance of an oil-resistant boot begins and ends with its sole. This is the component in direct contact with hazardous surfaces, and its composition is paramount.

What "Oil-Resistant" Truly Means

An oil-resistant rating ensures the boot's outsole maintains its structural integrity. Exposure to oil can cause standard rubber to swell and soften, dramatically reducing its durability and grip. Oil-resistant materials are engineered elastomers that resist this chemical breakdown.

This means the boot's traction, support, and protective qualities will not diminish even after repeated contact with petroleum-based or chemical substances.

Key Sole Materials

Three materials dominate the market, each offering a different balance of durability, comfort, and resistance.

- Rubber: Long considered the standard, rubber outsoles provide excellent resistance to oil and chemicals while offering superior traction on slick surfaces.

- Thermo-Polyurethane (TPU): TPU is a highly durable modern material known for its exceptional resistance to splitting, abrasion, and chemicals, making it a long-lasting choice.

- Ethylene-Vinyl Acetate (EVA): EVA is a lightweight, foam-like material prized for its cushioning and shock absorption. It is typically used in the midsole to provide comfort and reduce fatigue, often paired with a rubber or TPU outsole for durability.

Beyond the Sole: Critical Safety Features

While the sole addresses slip hazards, a true safety boot offers comprehensive protection from other common workplace risks.

Protective Toe Caps

The toe cap is your primary defense against impact and compression injuries.

- Steel Toes: The traditional choice, offering maximum protection but adding weight and conducting temperature.

- Aluminum Toes: Provide similar protection to steel but are significantly lighter.

- Composite Toes: Made from non-metal materials like carbon fiber or Kevlar, they are lightweight, do not conduct electricity, and don't transfer cold.

Electrical Hazard (EH) Protection

An Electrical Hazard (EH) rating is a critical feature for anyone working near live electrical circuits. These boots are designed with non-conductive soles and heels to provide a secondary source of protection against accidental electrocution.

Insulation and Environment

For those working in extreme temperatures, insulation is a key factor. Materials like Thinsulate or natural shearing provide warmth without excessive bulk, keeping feet comfortable in cold conditions.

Ensuring All-Day Performance and Comfort

A boot's safety features are only effective if the boot is worn properly and consistently. Comfort is not a luxury; it is a critical component of safety that reduces fatigue and distraction.

The Role of the Midsole

The midsole is the layer between the insole and the outsole. It is the primary source of cushioning and shock absorption. A supportive midsole, often made of EVA, is crucial for reducing the strain on your feet, knees, and back during long shifts.

Achieving the Perfect Fit

A poorly fitting boot can cause pain, blisters, and long-term foot problems, negating even the best safety features.

To ensure a proper fit, always shop for boots in the afternoon or evening when your feet have naturally swelled. Crucially, wear the same type of thick work socks you use on the job to get a true sense of the boot's size and feel.

Understanding the Trade-offs

Choosing the perfect boot always involves balancing competing priorities. Understanding these trade-offs is key to making an informed decision.

Durability vs. Comfort

The most rugged and durable boots, often featuring thick rubber soles and heavy-duty uppers, may also be the heaviest. This can lead to increased fatigue over a long day. Lighter boots with cushioned EVA midsoles may offer superior comfort but might not withstand the most abrasive environments as long.

Specialized Features vs. Cost

The price of safety boots can range significantly. Basic models provide essential oil resistance and toe protection. As you add specialized features like an EH rating, advanced waterproofing, or premium insulation, the cost will increase. Assess which features are "need-to-have" versus "nice-to-have" for your specific role.

Making the Right Choice for Your Job

Your final decision should be guided by the primary risks you face daily.

- If your primary focus is maximum slip prevention: Prioritize a boot with a high-traction rubber or TPU outsole featuring a deep, liquid-channeling tread pattern.

- If your primary focus is protection from impact and electrical risk: Ensure your boot has a certified steel, aluminum, or composite toe and a clearly stated Electrical Hazard (EH) rating.

- If your primary focus is all-day comfort to reduce fatigue: Pay close attention to boots with a cushioned EVA midsole, a supportive footbed, and dedicate time to achieving a perfect fit.

Ultimately, investing in the right boot is a direct investment in your daily safety, comfort, and ability to perform your job effectively.

Summary Table:

| Factor | Key Considerations | Importance |

|---|---|---|

| Sole Material | Rubber, TPU, or EVA midsole; oil-resistant rating | Prevents degradation, ensures slip resistance |

| Toe Protection | Steel, Aluminum, or Composite toe caps | Protects against impact/compression injuries |

| Safety Ratings | Electrical Hazard (EH) protection | Secondary protection against electrocution |

| Comfort & Fit | Midsole cushioning (EVA), proper sizing with work socks | Reduces fatigue, ensures all-day wearability |

| Work Environment | Insulation for temperature extremes, waterproofing | Adapts boot performance to specific job conditions |

Need Reliable, High-Quality Oil-Resistant Safety Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, including those with superior oil resistance, certified toe protection, and advanced comfort features.

We ensure durable performance and strict compliance with safety standards. Let us help you equip your workforce with the right protection.

Contact 3515 today for a quote and secure your supply of dependable safety footwear.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- What are the different types of safety toe caps? Choose the Right Protection for Your Job

- What is the transverse rigidity test for motorcycle boots? Decode Your Boot's Crush Protection

- How do high-strength protective safety shoes address the specific physical activity barrier of equipment damage?

- How do professional safety shoes function in industrial machining? Key Engineering for Maximum Workplace Protection

- How does the integration of Pressure Sensitive Resistor (FSR) sensors in smart safety shoes help in preventing injury?

- What is the primary function of medical safety protective shoes? Essential Foot Protection in Oral Clinical Settings

- What is the practical significance of identifying actions like putting on shoes? Enhancing Real-Time Industrial Safety

- How do slip-resistant outsoles in safety shoes mitigate the risk of physical imbalance? Boost Grip & Prevent Falls