The lifespan of a Goodyear-welted shoe is not a fixed number. It is a dynamic outcome determined by three primary variables: the quality of its materials, the frequency and intensity of your wear, and most importantly, the consistency of your maintenance routine. While these shoes are engineered for longevity, their potential to last for decades is unlocked only through active and informed care.

A Goodyear welt makes a shoe repairable, not invincible. Its legendary lifespan is a direct result of replacing worn-out components like the sole and heel over time, while diligently preserving the health of the leather upper.

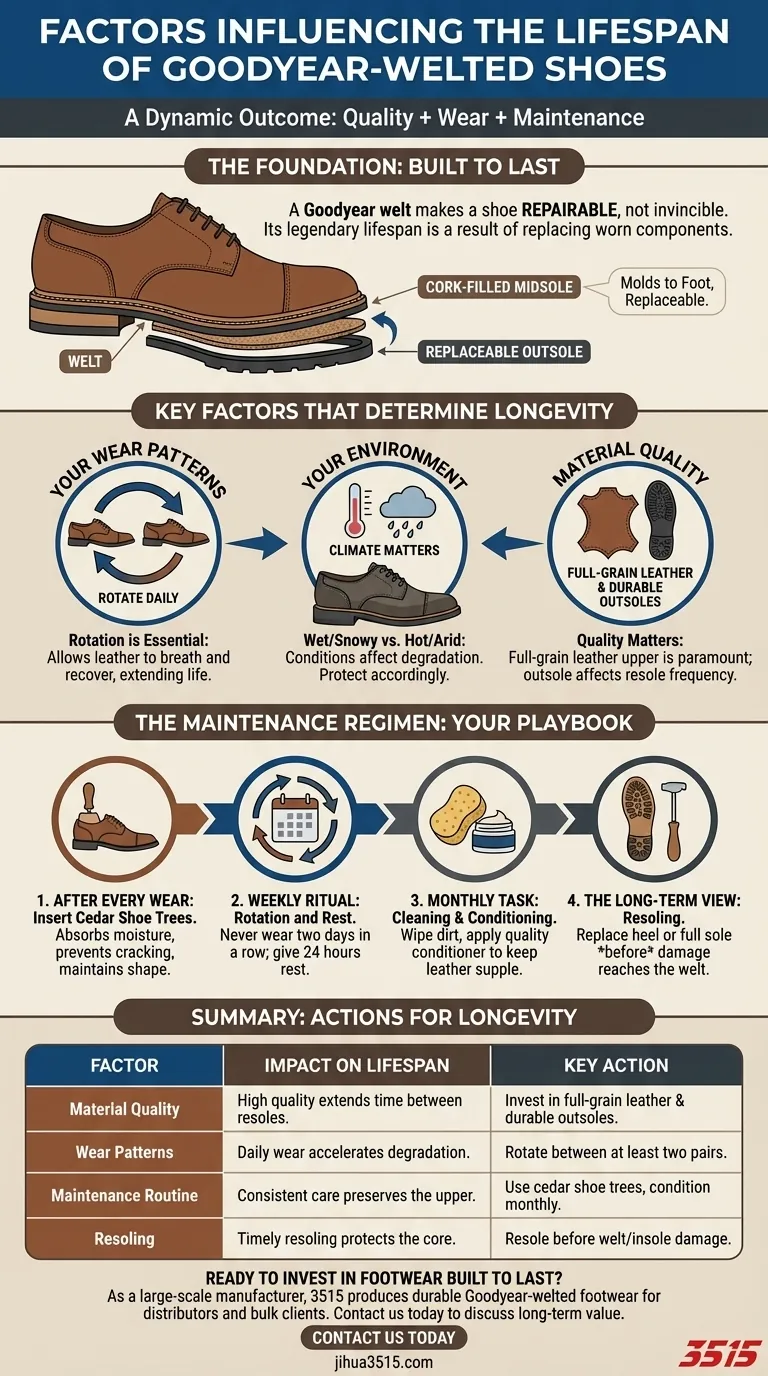

The Foundation: Why This Construction is Built to Last

To understand what influences the lifespan of these shoes, you first need to grasp the core principles of their construction. The durability is not accidental; it is a direct result of the design.

The Replaceable Outsole

The defining feature of this construction is the welt, a strip of leather stitched around the perimeter of the shoe. It connects the leather upper to the insole.

The outsole is then stitched directly to this welt, not to the upper. This mechanical separation is critical—it allows a cobbler to remove and replace a worn-out sole without compromising the shoe's core structure.

The Cork-Filled Midsole

Between the insole and outsole lies a cavity filled with cork. Over time, this cork filling compresses and molds to the unique shape of your foot, creating a custom-like fit.

During a resole, this cork can be replaced, essentially refreshing the shoe's supportive foundation and comfort from the inside out.

The Integrity of the Upper

The entire system relies on the leather upper remaining in good condition. The welt's primary function is to shield the upper from the stress of daily wear and the process of resoling. The lifespan of the upper is the ultimate limit on the lifespan of the shoe.

Key Factors That Determine Longevity

While the construction provides the potential for a long life, several external factors determine whether that potential is realized.

Your Wear Patterns

Wearing the same pair of shoes every single day is the fastest way to wear them out. Leather needs time to breathe and for moisture from your feet to evaporate completely.

Consistent rotation between at least two pairs is essential. This allows each pair to fully dry and recover its shape, dramatically extending the life of the leather and the internal components.

Your Environment

The climate you live in plays a significant role. Consistently wet or snowy conditions expose the leather and sole to moisture and salt, which can cause them to degrade.

Conversely, a hot, arid climate can dry out the leather, leading to cracking if it is not regularly conditioned.

The Quality of Materials

Not all Goodyear-welted shoes are created equal. The quality of the full-grain leather upper is paramount, as this is the part that cannot be easily replaced.

Similarly, the material of the insole and the type of outsole—be it durable leather or a hard-wearing rubber like Dainite—will have a major impact on how long the shoe lasts between resoles.

Understanding the Trade-offs: The Owner's Responsibility

The promise of a decades-long lifespan comes with necessary commitments from the owner. It is crucial to understand these trade-offs before investing.

The Myth of Invincibility

A shoe that "lasts for 20 years" does not mean it remains unchanged for 20 years. It means the shoe has been resoled multiple times and the upper has been diligently cared for.

Think of it less as a single product and more as a durable platform that you maintain and rebuild over time.

The Cost of Maintenance

Proper care is an investment of both time and money. Resoling is a skilled craft that carries a significant cost.

Furthermore, essential care products like quality cedar shoe trees, leather conditioners, creams, and polishes are necessary ongoing expenses to protect your initial investment.

The Upfront Commitment

The sturdy, multi-layered construction that makes these shoes so durable also means they often require a break-in period. They may feel stiff at first compared to more flexible, disposable footwear.

The Maintenance Regimen: Your Playbook for Longevity

A simple, consistent routine is the key to maximizing the life of your shoes.

After Every Wear: The Non-Negotiables

Always insert cedar shoe trees immediately after taking your shoes off. They absorb residual moisture, prevent the leather from cracking, and help the shoe maintain its proper shape.

The Weekly Ritual: Rotation and Rest

Never wear the same pair two days in a row. Giving your shoes at least 24 hours of rest on shoe trees is the single most effective habit for long-term preservation.

The Monthly Task: Cleaning and Conditioning

At least once a month, or more if exposed to harsh conditions, wipe down your shoes to remove dirt. Follow this by applying a high-quality leather conditioner or cream to restore oils and keep the leather supple and strong.

The Long-Term View: Resoling

The heel often wears down faster than the sole and can be replaced independently. A full resole is needed when the outsole develops a soft spot or a hole appears. Addressing this promptly prevents damage to the more critical midsole and welt.

How to Maximize the Lifespan for Your Goal

Your approach to care can be tailored to what you value most.

- If your primary focus is maximum longevity: Invest in high-quality shoe trees and rotate at least two pairs to ensure they dry completely between wears.

- If your primary focus is preserving appearance: Prioritize a regular cleaning and polishing routine to build a protective layer on the leather upper against scuffs and stains.

- If your primary focus is cost-effectiveness over time: Learn to identify when a resole is needed before damage occurs to the welt or insole, preventing more expensive, complex repairs down the line.

Ultimately, a Goodyear-welted shoe is a partnership; its remarkable lifespan is a direct reflection of the care you invest in it.

Summary Table:

| Factor | Impact on Lifespan | Key Action |

|---|---|---|

| Material Quality | High-quality leather and soles extend time between resoles. | Invest in full-grain leather and durable outsoles. |

| Wear Patterns | Daily wear accelerates degradation; rotation is essential. | Rotate between at least two pairs of shoes. |

| Maintenance Routine | Consistent care directly preserves the leather upper. | Use cedar shoe trees and condition leather monthly. |

| Resoling | Timely resoling protects the core structure of the shoe. | Resole before damage reaches the welt or insole. |

Ready to Invest in Footwear Built to Last?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable Goodyear-welted footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure you receive shoes crafted with the high-quality materials and construction detailed in this article.

Contact us today to discuss how our footwear solutions can provide long-term value and durability for your customers.

Visual Guide

Related Products

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

People Also Ask

- What are the key considerations when choosing dress shoes for formal occasions? A Guide to Style, Color & Quality

- How can one balance a casual outfit when wearing dress shoes? Achieve a Polished Smart Casual Look

- How should dress shoes be maintained to prolong their lifespan? A Guide to Lasting Quality

- What types of dress shoes are recommended for formal occasions? A Guide to Impeccable Style

- What are the long-term benefits of investing in quality dress shoes? Save Money & Boost Your Style