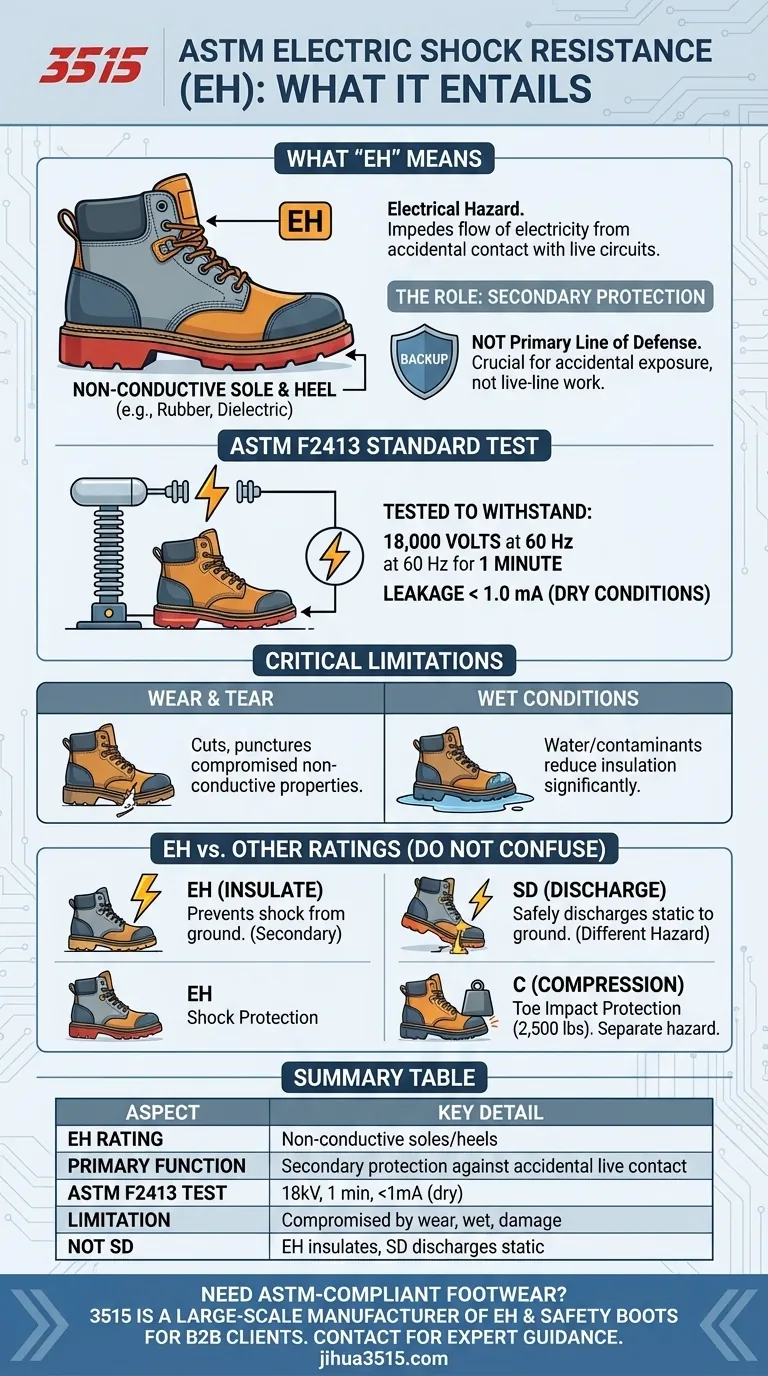

In the context of ASTM standards, electric shock resistance means that the footwear has been constructed with non-conductive soles and heels. These materials, such as rubber or dielectric compounds, are designed to protect the wearer from accidental contact with live electrical circuits by providing a barrier that impedes the flow of electricity. Footwear that meets this specific standard is clearly marked with an "EH" label.

The key takeaway is that EH-rated footwear provides a secondary source of protection against electrical shock. It is a crucial safety feature for specific environments but should never be considered the primary line of defense against electrical hazards.

The Role of EH-Rated Footwear

Understanding what the "EH" rating truly signifies is crucial for ensuring workplace safety. It's more than just a label; it's a specific performance standard for a particular type of hazard.

What "EH" Actually Means

The "EH" designation stands for Electrical Hazard. To earn this rating, the boot's entire outsole must be made from a non-conductive material. This construction is intended to provide protection against electrocution if you accidentally step on a live electrical conductor.

A Secondary Source of Protection

EH-rated boots are designed for workers who may be exposed to accidental electrical contact. This includes electricians, maintenance workers, and anyone working in construction or industrial settings where live wires could be present.

However, they are not intended for primary protection in live-line work, which requires specially designed and insulated equipment. Think of EH boots as a crucial backup, not the main tool for the job.

The Specific ASTM Standard

Under ASTM F2413, EH-rated footwear is tested to withstand the application of 18,000 volts at 60 Hz for one minute with no current flow or leakage current in excess of 1.0 milliampere under dry conditions. This specific test validates the sole's insulating properties.

Understanding the Critical Limitations

While EH-rated boots are a vital piece of personal protective equipment (PPE), their effectiveness is highly dependent on their condition and the environment in which they are used.

The Impact of Wear and Tear

The non-conductive properties of the sole can be compromised over time. Any cuts, punctures, or excessive wear can create a path for electricity to travel through the boot to the wearer.

The Critical Role of Conditions

The protection offered by EH boots is significantly reduced in wet, humid, or contaminated environments. Water and other conductive fluids can negate the sole's insulating properties, making regular inspection and maintenance essential.

Not a Substitute for Safety Protocols

EH-rated footwear is a component of a larger safety system. It does not replace established electrical safety protocols such as lockout/tagout (LOTO), proper insulation, and de-energizing circuits before work begins.

How EH Differs from Other Safety Ratings

The ASTM label on a work boot contains several ratings, and it's vital not to confuse them. A boot can have multiple ratings, each addressing a distinct hazard.

Electrical Hazard (EH) vs. Protective Toe (C)

The EH rating is completely separate from the boot's protection against physical impact. A protective toe, rated for Compression (C), is tested to withstand forces up to 2,500 pounds. This protects your toes from crushing, a fundamentally different hazard than electric shock.

Electrical Hazard (EH) vs. Static Dissipative (SD)

This is a common and dangerous point of confusion. While EH boots are designed to insulate you from the ground to prevent shock, Static Dissipative (SD) boots do the opposite. SD footwear is designed to safely discharge static electricity from your body to the ground, preventing sparks that could ignite flammable materials or damage sensitive electronics.

Making the Right Choice for Your Environment

Choosing the correct footwear depends entirely on a thorough assessment of the hazards present on your job site.

- If your primary focus is protection from accidental contact with live circuits: Ensure your boots are explicitly marked with the 'EH' rating and inspect them regularly for damage.

- If your primary focus is protection from falling or rolling objects: Look for the 'C' (Compression) and 'I' (Impact) ratings on the ASTM label to ensure your toes are protected.

- If your primary focus is preventing static discharge that could damage sensitive equipment: You must use Static Dissipative (SD) footwear, not EH-rated boots.

Understanding these distinct safety ratings is the first step toward ensuring your footwear provides the specific protection you actually need.

Summary Table:

| Aspect | Key Detail |

|---|---|

| EH Rating Meaning | Electrical Hazard; indicates non-conductive soles/heels. |

| Primary Function | Provides a secondary layer of protection against accidental contact with live circuits. |

| ASTM F2413 Test | Withstands 18,000 volts for 1 minute with minimal current leakage (under dry conditions). |

| Key Limitation | Protection is compromised by wear, damage, or wet/contaminated environments. |

| Not To Be Confused With | Static Dissipative (SD) footwear, which safely discharges static electricity. |

Need the right safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-compliant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of EH-rated and other safety shoes and boots, ensuring your workforce has the specific protection they need.

Contact us today for expert guidance and to discuss your footwear requirements.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- How do social media interactivity features enhance procurement engagement for tactical and work boots?

- What is Stitch-down Construction in work boots? Discover the Ultimate Durability and Stability

- What are the weatherproof benefits of work boots? Protect Your Feet from Water, Cold, and Slips

- What are the main benefits of composite toe work boots? Lighter, Safer, and More Comfortable

- What are inlays and stitching used for in cowboy boots? From Function to Fashion

- Why is comfort important in work boots? The Critical Link Between Comfort and Safety

- What role does the NFPA play in firefighting boot standards? Ensuring Certified Safety for Every Firefighter

- Why are moc toe boots popular? The Perfect Blend of Rugged Durability and Timeless Style