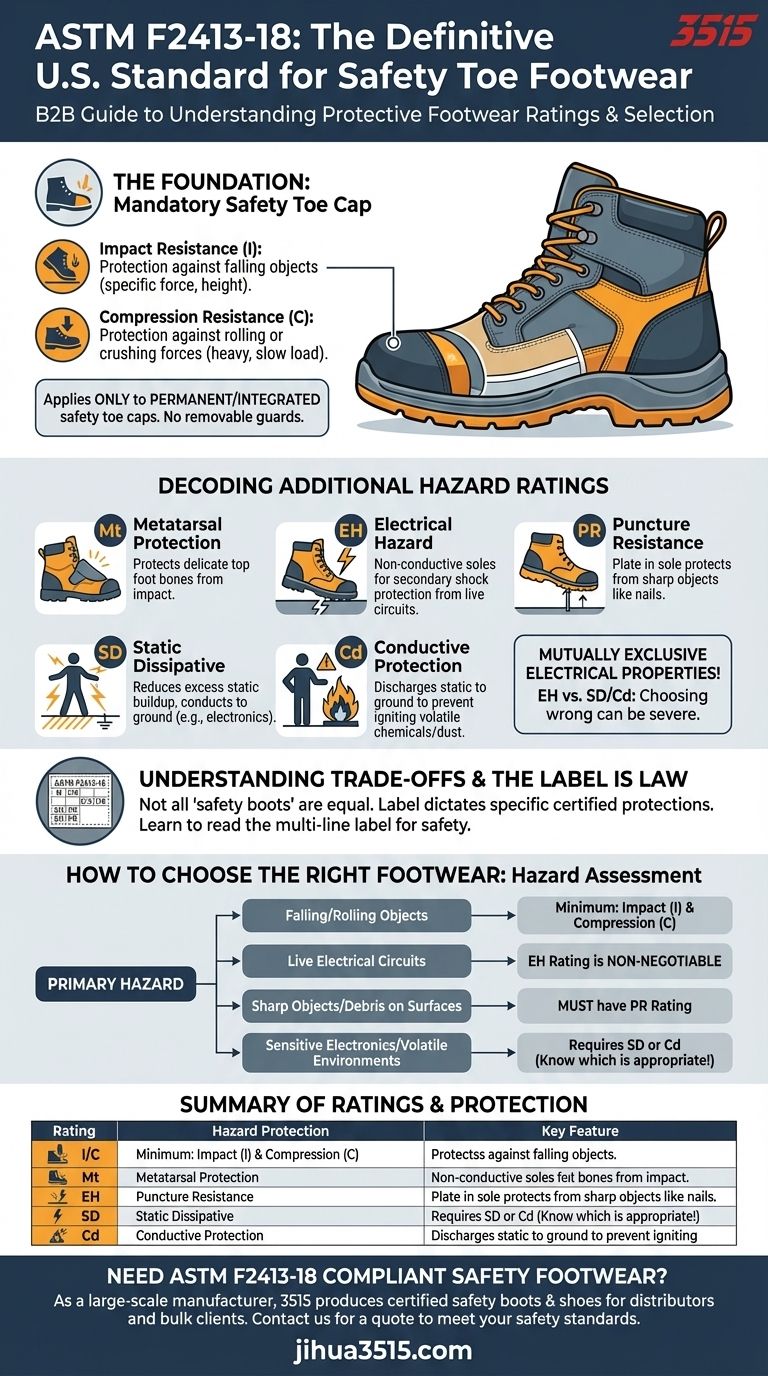

In short, ASTM F2413-18 is the definitive U.S. standard for safety toe footwear. It establishes the minimum performance requirements for boots designed to protect against a variety of workplace hazards, beginning with resistance to impact and compression. The standard also provides a framework for testing and labeling additional protections like electrical hazard resistance, puncture resistance, and more.

The most critical thing to understand is that ASTM F2413-18 is not a single, all-encompassing approval. It's a system of specific ratings for individual hazards. A boot's compliance tag tells you exactly which protections it has been tested and certified for.

The Foundation: Impact and Compression

All footwear compliant with ASTM F2413-18 must first meet the baseline requirements for the safety toe cap. This forms the core of the protective standard.

Impact Resistance (I)

This rating signifies protection against falling objects. The test measures the toe cap's ability to withstand a significant force dropped from a specific height.

Compression Resistance (C)

This rating signifies protection against rolling objects or compression forces. It tests the toe cap's ability to resist being crushed under a heavy, slow-moving load.

The Permanent Toe Cap Requirement

The standard exclusively applies to footwear manufactured with a permanent or integrated steel or composite toe cap. It does not cover removable guards or over-the-shoe protectors.

Decoding the Additional Hazard Ratings

Beyond the mandatory toe cap ratings, the standard outlines codes for specialized protections. These are found on the boot's label and are critical for matching the footwear to your specific work environment.

Metatarsal Protection (Mt)

This rating indicates the boot has an integrated guard that protects the delicate metatarsal bones on the top of the foot from impact.

Electrical Hazard (EH)

An EH rating means the footwear is manufactured with non-conductive, electrical-shock-resistant soles and heels. It provides a secondary source of protection against accidental contact with live electrical circuits.

Puncture Resistance (PR)

Footwear with a PR rating includes a puncture-resistant plate positioned in the sole to protect the foot from sharp objects like nails or scrap metal.

Static Dissipative (SD)

SD footwear is designed to reduce the buildup of excess static electricity by conducting it from the body to the ground. This is crucial in environments sensitive to static discharge, such as electronics manufacturing.

Conductive Protection (Cd)

Conductive (Cd) footwear is designed to discharge static electricity from your body into the ground to protect against igniting volatile chemicals or dust. It offers no protection from electrical hazards.

Understanding the Trade-offs and Limitations

Choosing the right boot requires understanding that no single piece of footwear protects against everything. The label is your guide to its specific capabilities and limitations.

Not All "Safety Boots" Are Equal

A boot can be ASTM F2413-18 compliant by meeting only the basic Impact (I) and Compression (C) standards. If your job requires protection from electrical hazards or punctures, you must verify the label explicitly states EH or PR.

EH vs. SD vs. Cd: A Critical Distinction

These electrical properties are mutually exclusive. A boot designed to insulate you from a live current (EH) cannot also be designed to dissipate static electricity (SD or Cd). Choosing the wrong one for your environment can have severe consequences.

The Label is Law

The standard dictates a specific labeling format that clearly identifies which protections the footwear provides. Learning to read this multi-line label is the most important skill for ensuring your safety.

How to Choose the Right Footwear

Your choice must be guided by a thorough hazard assessment of your workplace. Use the boot's label to match its certified protections to your specific needs.

- If your primary hazard is falling or rolling objects: Ensure the boot is, at a minimum, rated for Impact (I) and Compression (C).

- If you work near live electrical circuits: The EH rating is non-negotiable and provides a critical secondary layer of protection.

- If you walk on surfaces with nails or sharp debris: You must select footwear with the PR (Puncture Resistant) rating.

- If you work in sensitive electronics or volatile environments: You will require either SD (Static Dissipative) or Cd (Conductive) footwear, and you must know which is appropriate for your specific task.

By understanding these codes, you move beyond simple compliance and make an informed choice that truly protects you on the job.

Summary Table:

| ASTM F2413-18 Rating | Hazard Protection | Key Feature |

|---|---|---|

| I/C | Impact & Compression | Mandatory safety toe cap protection |

| Mt | Metatarsal | Protects bones on top of the foot |

| EH | Electrical Hazard | Shock-resistant soles for live circuits |

| PR | Puncture Resistance | Plate in sole protects from sharp objects |

| SD | Static Dissipative | Reduces static buildup (electronics) |

| Cd | Conductive | Discharges static (volatile environments) |

Need ASTM F2413-18 Compliant Safety Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, ensuring your workforce has the right protection against impact, compression, electrical hazards, punctures, and more.

Contact us today for a quote and let us help you meet your safety standards with reliable, high-quality footwear.

Visual Guide

Related Products

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

People Also Ask

- What are the disadvantages of alloy toe boots? Weighing Comfort vs. Protection

- How do the physical characteristics of industrial safety shoes or tactical boots affect ground vibration features?

- What are the advantages of composite toe caps? Lightweight, Non-Conductive Safety for All-Day Comfort

- What are the key requirements for ASTM F2413 conforming safety footwear? A Guide to Selecting the Right Protection

- What type of sole design is recommended for fire boots? Lug Soles for Superior Traction & Safety

- What materials are used in composite toes for oil-resistant safety boots? Discover the Non-Metallic Advantage

- Does OSHA allow composite toe boots? Understanding Compliance and Safety Standards

- What role do Gyroscopic Sensors play in fall detection systems? Enhancing Safety in Industrial Footwear