At its core, a PVC work boot is distinguished from other types by its material and manufacturing process. Unlike leather or stitched rubber boots, PVC (polyvinyl chloride) boots are created through injection molding, forming a single, seamless, and non-porous shell that offers an absolute barrier against water, chemicals, and contaminants.

The critical distinction is not just the material itself, but how it's formed. The injection-molding process eliminates seams—the weakest point in most footwear—making PVC boots uniquely suited for environments where complete liquid protection is non-negotiable.

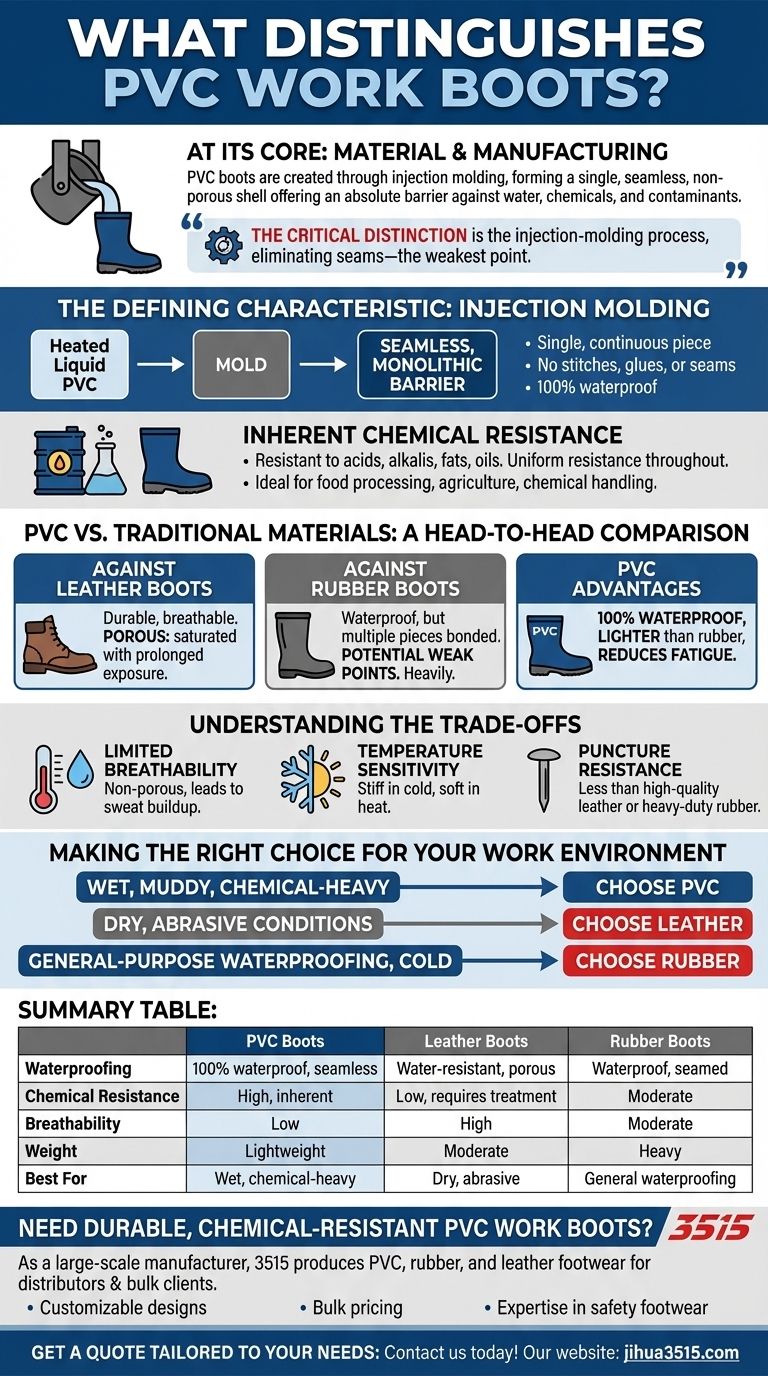

The Defining Characteristic: Injection Molding

The way a PVC boot is made is fundamental to its performance. It’s a process that sets it apart from boots constructed from multiple pieces of leather or rubber.

A Seamless, Monolithic Barrier

Heated, liquid PVC is injected into a mold that shapes the entire boot at once. As it cools, it solidifies into a single, continuous piece.

This monolithic construction means there are no stitches, glues, or seams that can leak or fail over time. It provides a level of waterproofing that is nearly impossible to achieve with stitched materials.

Inherent Chemical Resistance

PVC is a synthetic polymer inherently resistant to a wide range of substances, including acids, alkalis, fats, and oils. This resistance is uniform throughout the boot, not just a surface treatment.

This makes PVC an essential choice for industries like food processing, agriculture, and chemical handling, where exposure to corrosive or contaminating substances is a daily reality.

PVC vs. Traditional Materials: A Head-to-Head Comparison

Understanding how PVC stacks up against leather and rubber clarifies its specific advantages and disadvantages for different job requirements.

Against Leather Boots

Leather is known for its durability, abrasion resistance, and breathability. However, it is naturally porous.

While leather can be treated to be water-resistant, it will eventually become saturated with prolonged exposure. PVC is 100% waterproof from the start and will never absorb liquids.

Against Rubber Boots

Rubber boots are also waterproof, but they are typically constructed from multiple pieces of vulcanized rubber that are bonded together. This can still create potential weak points.

PVC is often lighter than rubber, reducing worker fatigue over long shifts. Furthermore, its injection-molded construction offers a more reliable seamless barrier.

Comfort and Weight

Despite its rugged protective qualities, PVC is a surprisingly lightweight material. This reduction in weight contributes directly to greater comfort and agility, making a significant difference during a full day of labor.

Understanding the Trade-offs

No material is perfect for every application. Being an effective advisor means acknowledging the limitations of PVC to ensure it’s chosen for the right reasons.

Limited Breathability

The very feature that makes PVC completely waterproof—its non-porous nature—is also its biggest drawback. PVC boots do not breathe.

This can lead to sweat and moisture buildup inside the boot. This is typically managed by wearing moisture-wicking socks, but it's a critical comfort consideration for hot environments.

Temperature Sensitivity

PVC's flexibility can be affected by extreme temperatures. In severe cold, the material can become stiff and more prone to cracking. In extreme heat, it can become overly soft.

Puncture Resistance

While durable against chemicals and water, standard PVC may offer less puncture resistance compared to a thick, high-quality leather or a specially formulated, heavy-duty rubber boot. For environments with sharp objects, this trade-off is crucial.

Making the Right Choice for Your Work Environment

Your decision should be driven entirely by the primary hazards and demands of your job.

- If your primary focus is working in wet, muddy, or chemical-heavy environments: Choose PVC for its seamless, 100% waterproof, and chemically resistant properties.

- If your primary focus is all-day comfort in dry conditions with abrasion risk: A high-quality leather boot is likely a better choice due to its superior breathability and toughness.

- If your primary focus is general-purpose waterproofing with more flexibility in the cold: A high-quality rubber boot might be more suitable, though you may sacrifice some chemical resistance and gain weight.

By matching the material's inherent strengths to your specific work environment, you can ensure you have the right protection and comfort for the job.

Summary Table:

| Feature | PVC Boots | Leather Boots | Rubber Boots |

|---|---|---|---|

| Waterproofing | 100% waterproof, seamless | Water-resistant, porous | Waterproof, seamed |

| Chemical Resistance | High, inherent to material | Low, requires treatment | Moderate |

| Breathability | Low | High | Moderate |

| Weight | Lightweight | Moderate | Heavy |

| Best For | Wet, chemical-heavy environments | Dry, abrasive conditions | General waterproofing |

Need durable, chemical-resistant PVC work boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of PVC, rubber, and leather footwear for distributors, brand owners, and bulk clients. Our injection-molded PVC boots provide seamless, 100% waterproof protection ideal for food processing, agriculture, and chemical handling industries.

We offer:

- Customizable designs for your brand

- Bulk pricing for large orders

- Expertise in safety footwear manufacturing

Get a quote tailored to your needs: Contact us today to discuss your requirements!

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- Why is Goodyear welt construction preferred for work boots? For Unmatched Durability & Repairability

- What makes work boots durable? The 3 Key Factors for Long-Lasting Footwear

- How do professional-grade protective boots manage thermal protection? Master Heat Resistance for Safer Riding

- What are oilfield boots designed for? Unmatched Protection for Rig Workers

- What types of outsoles are available for different work environments? Choose the Right Grip for Your Job

- What is the difference between roper heel and cowboy heel boots? Choose the Right Heel for Your Work

- What are some common toe shapes in Western boots? A Guide to Fit, Style, and Comfort

- How did engineer boots evolve from workwear to fashion items? A Symbol of Rebellion and Style