The U.S. Army's requirements for jungle combat boots are a direct response to the unique challenges of a jungle environment, focusing on rapid water drainage, superior traction in mud, and protection from unseen hazards underfoot. These boots blend Vietnam-era design principles with modern materials, featuring leather and nylon uppers, a specialized Panama-style rubber outsole, a shock-absorbing polyurethane midsole, multiple drainage holes, and a flexible, puncture-resistant insole.

The core principle behind the Army's Jungle Combat Boot (JCB) is not to keep water out, which is impossible in a jungle, but to let water drain as quickly as possible. This design philosophy prioritizes foot health and mobility in perpetually wet, treacherous conditions.

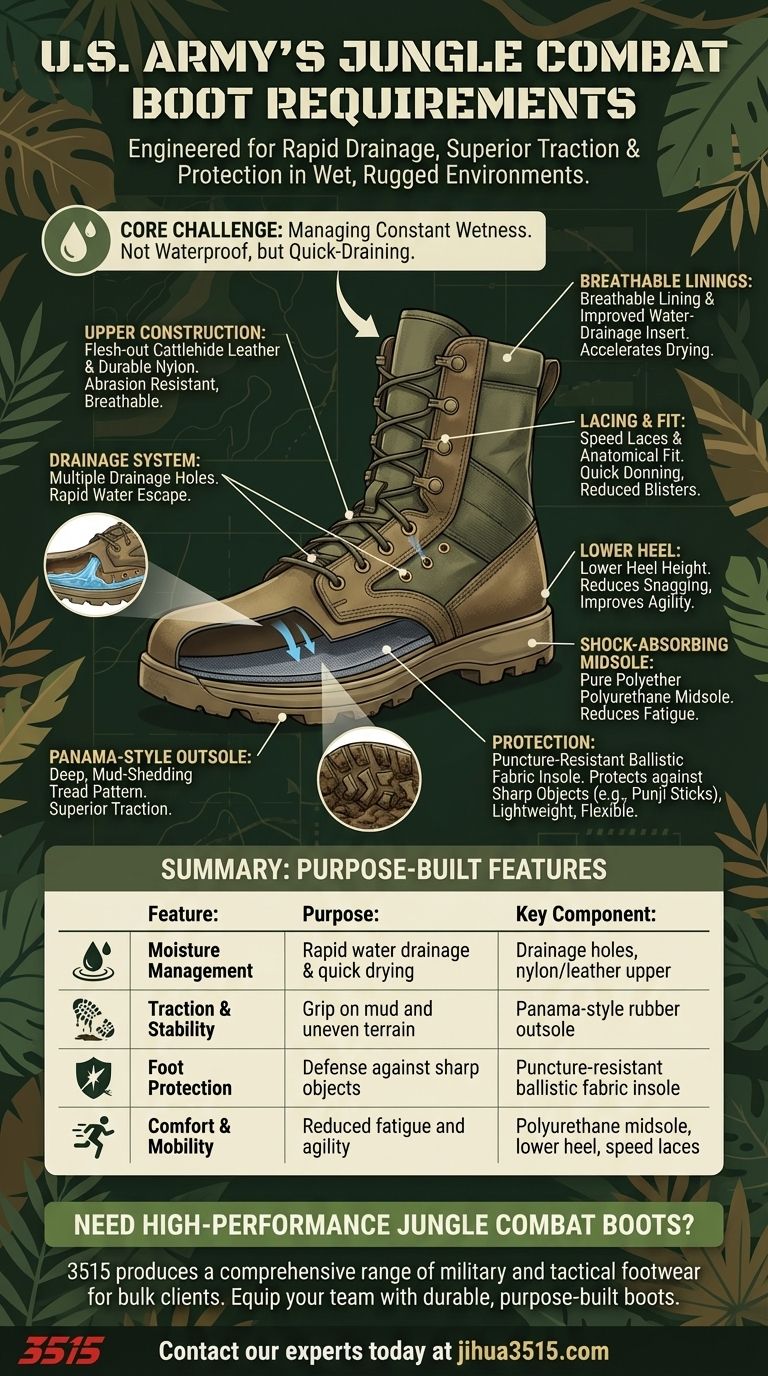

The Core Challenge: Managing Constant Wetness

In a jungle environment, keeping feet dry is an unrealistic goal. The Army's design acknowledges this reality by creating a boot that manages moisture, rather than attempting to block it entirely.

Quick-Drying Upper Construction

The upper portion of the boot is constructed from a combination of flesh-out cattlehide leather and durable nylon. This pairing provides abrasion resistance while avoiding the moisture retention common in heavier, all-leather boots.

The Drainage System

A key feature is the inclusion of multiple drainage holes, typically on the inner arch. These ports allow water that floods the boot to escape quickly as the soldier walks, preventing the foot from being constantly submerged.

Breathable Linings and Inserts

To complement the drainage holes, the boot utilizes a breathable lining and an improved water-drainage insert. These components work together to accelerate the drying process once the soldier is out of the water, reducing the risk of fungal infections and immersion foot.

Engineering for Treacherous Terrain

Jungle terrain is characterized by deep mud, tangled roots, and uneven ground. The boot's lower half is specifically engineered to provide stability and traction in these conditions.

The Panama-Style Outsole

The JCB features a rubber outsole with a deep, mud-shedding tread pattern similar to the historic "Panama" sole. The wide, angled lugs are designed to grip soft ground effectively while preventing mud from caking and reducing traction.

Shock-Absorbing Midsole

A pure polyether polyurethane midsole is directly attached between the upper and the outsole. This modern addition provides crucial shock absorption, reducing fatigue during long patrols on hard, uneven surfaces.

A Lower Heel for Agility

Compared to older designs, the modern JCB has a lower heel height. This subtle change reduces the likelihood of the heel snagging on vines, roots, and other jungle undergrowth, improving soldier mobility and preventing falls.

Modernizing Soldier Protection

Beyond environmental challenges, the jungle floor hides potential dangers. The modern JCB incorporates advanced protective features that are more effective and comfortable than their predecessors.

From Steel Plate to Ballistic Fabric

Instead of the rigid steel plate used in Vietnam-era boots, the JCB now uses a puncture-resistant ballistic fabric layer. This provides robust protection against sharp objects like punji sticks while being significantly lighter and more flexible, enhancing comfort and reducing fatigue.

Enhanced Fit and Lacing

The boot's upper has been redesigned for a better anatomical fit, reducing blisters and hot spots. The inclusion of speed laces allows soldiers to don and doff the boots quickly, which is critical in tactical situations.

Understanding the Trade-offs

No single boot is perfect for every environment, and the JCB is a highly specialized piece of equipment.

Not a General-Purpose Boot

The very features that make the JCB excel in the jungle make it less suitable for other climates. The drainage holes are a liability in cold, wet conditions, and the aggressive tread can wear quickly on concrete or asphalt.

"Waterproof" vs. "Quick-Draining"

It is critical to understand that the JCB is not waterproof. Its design philosophy is the opposite of waterproof boots like those using a Gore-Tex membrane. In a jungle, a waterproof boot that gets flooded will stay flooded, creating a severe health hazard for the soldier's feet.

Making the Right Choice for Your Goal

Understanding the design intent behind the Jungle Combat Boot allows for proper selection and use.

- If your primary focus is military compliance: Ensure the boot you select is AR 670-1 compliant and is specifically designated as a Jungle Combat Boot.

- If your primary focus is performance in hot, wet environments: Prioritize boots with prominent, non-locking drainage ports and Panama-style outsoles over traditional waterproof designs.

- If your primary focus is protection from ground hazards: Verify the boot contains a modern, flexible puncture-resistant layer rather than a simple steel shank for superior comfort and safety.

Ultimately, the modern Jungle Combat Boot is a purpose-built tool engineered not to fight the jungle's wetness, but to master it.

Summary Table:

| Feature | Purpose | Key Component |

|---|---|---|

| Moisture Management | Rapid water drainage & quick drying | Drainage holes, nylon/leather upper |

| Traction & Stability | Grip on mud and uneven terrain | Panama-style rubber outsole |

| Foot Protection | Defense against sharp objects | Puncture-resistant ballistic fabric insole |

| Comfort & Mobility | Reduced fatigue and agility | Polyurethane midsole, lower heel, speed laces |

Need to source high-performance jungle combat boots? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of military and tactical boots, including designs that meet the demanding requirements for wet, rugged environments. Let us help you equip your team with durable, purpose-built footwear. Contact our experts today to discuss your manufacturing needs.

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

People Also Ask

- Why choose leather over suede for desert boots? For superior durability and all-weather protection.

- What are some key design features of the new jungle combat boot? Engineered for Hot, Wet Environments

- What are the requirements for boot height and materials according to DA PAM 670-1? Ensure Full Compliance

- What issue does the standard-issue combat boot have in certain environments? Why They Fail in Hot & Wet Conditions

- How did the desert boot design become popular after World War II? A Tale of Style & Counter-Culture

- How does the new boot's construction improve durability in wet conditions? Prevent Delamination with a Microbial Barrier

- What are jungle boots and what environments are they suited for? Master Hot, Wet Terrain

- Why are professional racing boots or off-road boots essential for high-risk riding? Maximize Your Skeletal Protection