When working on the fire line, the material of your boot upper is a critical safety feature, not a style choice. The uppers of wildland firefighter boots are almost exclusively made from thick, high-quality leather. This is a strict requirement mandated by safety standards like those from the National Fire Protection Agency (NFPA) due to leather's unique durability and resistance to ignition in extreme heat.

The selection of leather for wildland boot uppers is not a matter of tradition but a non-negotiable safety requirement. Unlike synthetic materials that can melt and cause severe burns, properly treated leather provides a durable, heat-resistant barrier essential for frontline protection.

Why Leather is the Standard for Wildland Fire Boots

The choice of material for a wildland fire boot is dictated by the unforgiving environment in which it must perform. Leather has proven to be the only widely accepted material that meets these demands.

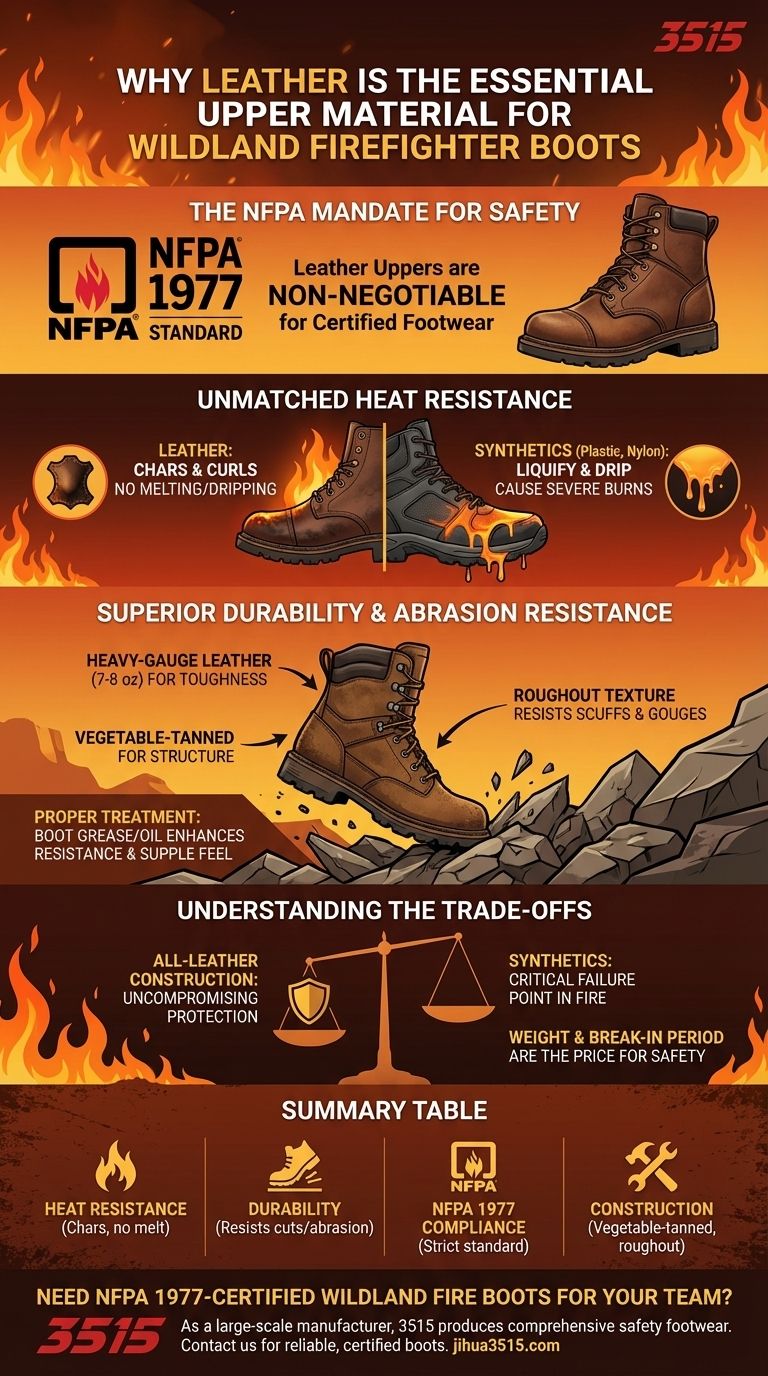

The NFPA Mandate for Safety

The NFPA 1977 standard, which governs protective clothing and equipment for wildland fire fighting, explicitly requires boots to be constructed from leather. This removes ambiguity and ensures a baseline level of protection for all certified footwear.

Unmatched Heat Resistance

The primary reason for the leather requirement is its behavior under extreme heat. Leather will char and curl when exposed to flame, but it will not melt or drip. This is a critical distinction from synthetic alternatives.

Materials like plastic, rubber, or even nylon can liquify at high temperatures. Molten material sticking to skin can cause devastating burns, making such materials completely unsuitable and dangerous for firefighting.

Superior Durability and Abrasion Resistance

Wildland firefighters navigate incredibly rugged terrain, from sharp rocks to abrasive ash and debris. Boot uppers must withstand constant punishment without failing.

Premium, heavy-gauge leather (typically 7 to 8 oz) provides the necessary toughness to resist cuts, punctures, and abrasion, protecting the firefighter's foot and ensuring the structural integrity of the boot.

Deconstructing the "Right" Kind of Leather

Not all leather is created equal. The specific type and treatment of the leather used in a quality fire boot are chosen to maximize performance and longevity.

Vegetable-Tanned for Structure

The uppers are often made from vegetable-tanned leather. This traditional tanning process results in a stiffer, harder leather that holds its shape well under stress, providing crucial ankle support on uneven ground.

The Function of Roughout Texture

Many wildland boots use "roughout" leather, where the rough, flesh side of the hide faces outward. This is not a stylistic choice. The rough texture is more resistant to scuffs and gouges than the smooth grain side, effectively hiding damage and extending the usable life of the boot.

The Importance of Proper Treatment

The fire-resistant properties of leather are significantly enhanced by proper care. Applying boot grease or oil keeps the leather supple, prevents it from drying and cracking, and improves its ability to repel water and resist heat.

Understanding the Trade-offs

While leather is the required standard, it's important to understand its properties in contrast to other materials used in general-purpose boots. Acknowledging its limitations highlights why no other material has been able to replace it for this specific application.

The Critical Failure of Synthetics

Modern hiking and work boots often incorporate synthetic materials like engineered mesh or nylon for reduced weight and increased breathability. While excellent for recreation, these materials represent a critical point of failure in a fire environment due to their low melting point.

Weight and Break-In Period

The most significant trade-offs for all-leather construction are weight and comfort. A thick leather fire boot is heavy and typically requires a substantial break-in period before it conforms to the wearer's foot. This is the price paid for uncompromising protection.

How to Ensure Your Boots Meet the Standard

When selecting footwear, your goal will determine the most important factors to consider.

- If your primary focus is meeting official safety requirements: Always choose a boot that is explicitly NFPA 1977 certified, which guarantees an all-leather upper construction that has passed rigorous testing.

- If your primary focus is maximum durability in rugged terrain: Look for boots made from thick (7oz or higher) vegetable-tanned, roughout leather for the best possible abrasion resistance.

- If you are considering a non-leather boot: Understand that while it may be lighter or require less break-in, it is not suitable for wildland fire conditions and poses a significant safety risk.

Choosing the right material isn't just about performance; it's a foundational element of your safety on the fire line.

Summary Table:

| Material Property | Why It Matters for Wildland Fire Boots |

|---|---|

| Heat Resistance | Leather chars but won't melt or drip, preventing severe burns unlike synthetics. |

| Durability | Thick (7-8 oz) leather resists cuts, punctures, and abrasion from rugged terrain. |

| NFPA 1977 Compliance | Certification ensures the boot upper meets strict safety standards for wildfire fighting. |

| Construction | Vegetable-tanned, roughout leather provides superior structure and damage resistance. |

Need NFPA 1977-Certified Wildland Fire Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of NFPA-compliant boots built with the durable, heat-resistant leather uppers essential for firefighter safety.

Contact 3515 today to discuss your specific requirements for reliable, certified wildland fire boots. We ensure the protection and performance your teams depend on.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Lightweight Tactical Boots Custom Manufacturer for Desert & Combat Use

People Also Ask

- What is the primary purpose of soft-toe boots? Prioritize All-Day Comfort & Agility

- Why is it important to tie your work boots properly? Secure Your Safety and Boost Comfort

- Why is hydraulic oil resistance necessary for Work Boots? Essential Safety for Agricultural Heavy-Duty Maintenance

- Are cowboy boots popular outside the United States? Exploring Global Appeal and Key Markets

- How does the use of a 50th percentile male body model improve the ergonomic design of industrial work boots?

- Why is it necessary to equip workers with heavy-duty work boots? Essential Safety for Industrial & Construction Sites

- How should motorcycle boots fit for optimal use? A Guide to Safety and Comfort

- How can you ensure a comfortable fit when selecting oilfield work boots? A Guide to All-Day Comfort & Safety