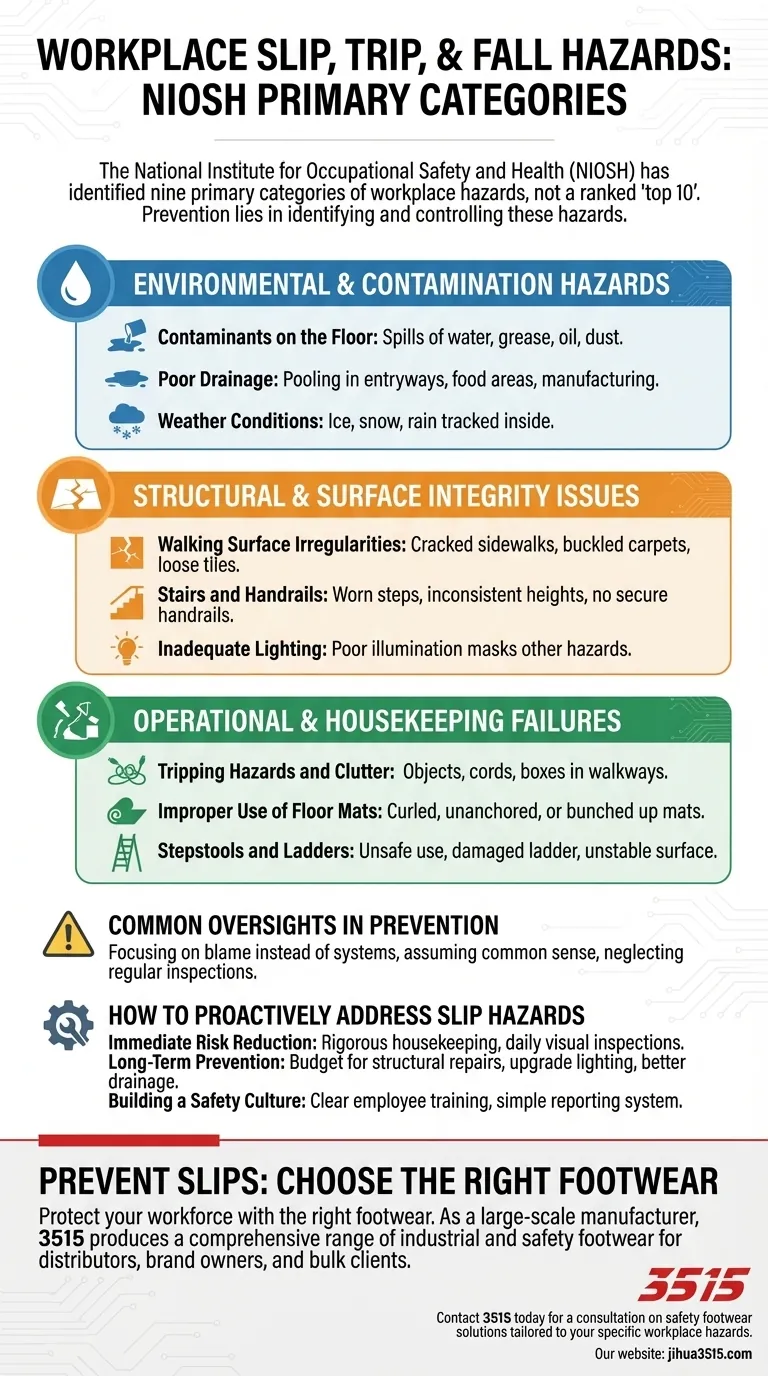

To directly answer your question, the National Institute for Occupational Safety and Health (NIOSH) has identified nine primary categories of workplace slip, trip, and fall hazards rather than a ranked "top 10." These hazards range from surface contaminants and poor drainage to structural issues like irregular walking surfaces and inadequate lighting.

The core principle of workplace safety is recognizing that most slips and falls are not random accidents but predictable outcomes of environmental failures. The key to prevention lies in systematically identifying and controlling these hazards, not just reacting to incidents.

Environmental & Contamination Hazards

These hazards relate to substances or conditions that temporarily make a walking surface unsafe. They are often the most common and require constant vigilance.

Contaminants on the Floor

Any foreign substance on a walking surface can dramatically reduce traction. This includes spills of water, grease, oil, or even fine powders like dust.

Poor Drainage

Areas where liquids are used must have adequate drainage to prevent pooling. This is critical in entryways, food service areas, and manufacturing floors where water can accumulate.

Weather Conditions

Ice, snow, and rain are significant hazards, not just outdoors but also when tracked inside on shoes. This creates slick, unexpected wet spots on otherwise dry floors.

Structural & Surface Integrity Issues

These hazards are built into the physical environment. They are often persistent risks that require structural repair or modification to mitigate effectively.

Walking Surface Irregularities

This category covers any damage or defect in the floor itself. Examples include cracked sidewalks, buckled carpets, loose tiles, or uneven transitions between different types of flooring.

Stairs and Handrails

Worn or damaged steps, inconsistent riser heights, and a lack of secure, continuous handrails create a high-risk environment for falls. The edge of each step must be clearly visible.

Inadequate Lighting

Poor lighting can mask other hazards, making it impossible for employees to see a spill, a crack in the floor, or an object in their path. Proper illumination is a foundational safety requirement.

Operational & Housekeeping Failures

This group of hazards arises from how a space is used, maintained, and organized. These are often the easiest to fix through consistent procedures and employee training.

Tripping Hazards and Clutter

Objects left in walkways are a primary cause of trips. This includes electrical cords, boxes, tools, and any equipment not stored in its proper place.

Improper Use of Floor Mats

While intended to improve safety, floor mats can become a hazard themselves. Mats that are curled, unanchored, or bunched up can easily cause a trip.

Stepstools and Ladders

Unsafe use of ladders and stepstools is a major cause of falls from height. This includes using a damaged ladder, placing it on an unstable surface, or over-reaching while on it.

Beyond the List: Common Oversights in Prevention

Simply knowing the list of hazards is not enough. True prevention requires avoiding common institutional blind spots that undermine safety efforts.

Focusing on Blame Instead of Systems

A frequent mistake is to attribute a fall to employee "carelessness." In reality, most incidents are symptoms of a systemic failure, such as a lack of a cleanup protocol or a known, unrepaired leak.

Assuming Common Sense is Common Practice

Never assume employees will automatically know how to identify or react to a hazard. Effective safety relies on explicit training, clear signage, and consistent reinforcement of safe procedures.

Neglecting Regular Inspections

Work environments are dynamic. A safe walkway one day can be hazardous the next. Implementing a routine schedule of safety inspections is critical for proactively identifying and addressing risks before an incident occurs.

How to Proactively Address Slip Hazards

Use this framework to turn knowledge into a concrete action plan for your workplace.

- If your primary focus is immediate risk reduction: Implement rigorous housekeeping protocols for clutter and spills, and conduct daily visual inspections of high-traffic areas.

- If your primary focus is long-term prevention: Budget for structural repairs to floors and stairs, upgrade lighting where needed, and engineer better drainage solutions in problem areas.

- If your primary focus is building a safety culture: Develop clear employee training on hazard identification and create a simple, no-blame system for reporting potential risks.

A proactive approach to managing your environment is the most effective way to ensure a safe workplace for everyone.

Summary Table:

| Hazard Category | Specific Examples |

|---|---|

| Environmental & Contamination | Spills (water, oil), poor drainage, tracked-in rain/snow |

| Structural & Surface Integrity | Cracked floors, uneven stairs, inadequate lighting |

| Operational & Housekeeping | Clutter in walkways, unanchored mats, unsafe ladder use |

Protect your workforce with the right footwear. Slips and falls are often preventable with the correct safety gear. As a large-scale manufacturer, 3515 produces a comprehensive range of industrial and safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of non-slip shoes and boots designed for hazardous environments. Let us help you equip your team with durable, reliable footwear to mitigate these risks.

Contact 3515 today for a consultation on safety footwear solutions tailored to your specific workplace hazards.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

People Also Ask

- What is the purpose of the robotic pressing procedure? Boost Footwear Yield Rates with Precise Outsole Stabilization

- Why is high-performance GPU computing necessary for training gait analysis models for specific footwear applications?

- How does an industrial-grade hot press molding machine contribute to the production of leather composite sheets?

- Why is it mandatory to equip footwear pressing and gluing areas with industrial exhaust fans? Boost Safety & Quality

- Why are high-precision optical motion capture systems necessary for assessing athletic performance in footwear testing?

- What is the mechanism of industrial-grade fiber-to-fiber recycling? 3515 Guide to Circular Footwear Production

- What is shoe 'drop' and why is it important? Align Your Footwear with Your Biomechanics

- How does personalization in footwear manufacturing enhance brand value? Drive Loyalty Through Customization Strategies