At its core, every protective footwear standard is built upon three essential pillars: defining the physical performance requirements the footwear must meet, specifying the rigorous testing methods to verify that performance, and mandating a consistent labeling format for clear identification and compliance. This system ensures that a safety shoe's protective capabilities are both proven and easily understood.

The purpose of safety footwear standards is not just to set rules, but to create a transparent and reliable system. This system allows employers and workers to trust that the certified footwear will perform as expected against specific workplace hazards.

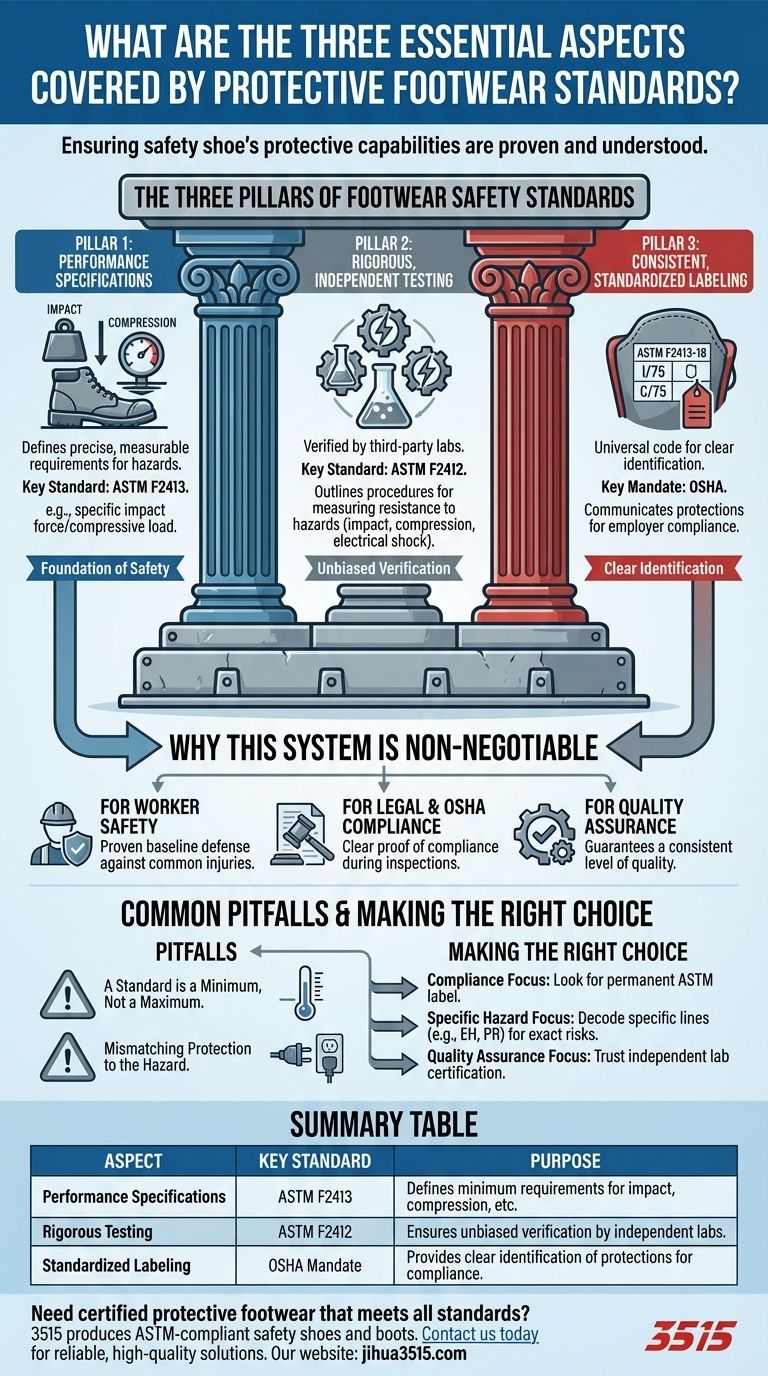

The Three Pillars of Footwear Safety Standards

To ensure footwear is genuinely protective, standards bodies like ASTM International have established a comprehensive framework. This framework rests on three interconnected components that work together to guarantee safety and compliance.

Pillar 1: Performance Specifications

Performance specifications are the foundation of any safety standard. They are the specific, measurable requirements that a piece of protective footwear must meet to be considered safe for a particular hazard.

These are not vague goals; they are precise benchmarks. For example, a standard will define the exact amount of impact force (in joules) or compressive load (in pounds) a safety toe must withstand without failing.

The key standard governing these requirements is ASTM F2413, which specifies the minimum requirements for the design, performance, testing, and classification of protective footwear.

Pillar 2: Rigorous, Independent Testing

A specification is only meaningful if it can be verified. This is where rigorous testing comes in.

To earn certification, footwear must be tested by an independent, third-party laboratory. This ensures unbiased results and prevents manufacturers from grading their own products.

The standard ASTM F2412 defines these testing protocols. It outlines the precise procedures and equipment that labs must use to measure resistance to various hazards, such as impact, compression, and electrical shock.

Pillar 3: Consistent, Standardized Labeling

The final pillar ensures the information is communicated clearly. After a shoe passes testing, it must be marked with a standardized label.

This label acts as a universal code, allowing anyone to quickly identify the specific protections the footwear offers. This is critical for employers needing to comply with Occupational Safety and Health Administration (OSHA) regulations.

The label will clearly state the standard it conforms to (e.g., ASTM F2413-18) and use specific codes for each hazard it protects against, such as I/75 for impact and C/75 for compression.

Why This System is Non-Negotiable

Adhering to this three-part system provides critical assurances for everyone, from the manufacturer to the end-user. It moves safety from a subjective claim to an objective, verifiable fact.

For Worker Safety

The most important outcome is the protection of workers. A certified shoe provides a proven, baseline level of defense against common workplace foot injuries in industrial, construction, and service fields.

For Legal & OSHA Compliance

For employers, using certified protective footwear is a core requirement of OSHA's Personal Protective Equipment (PPE) standards. The standardized label serves as clear proof of compliance during a workplace inspection.

For Quality Assurance

This system holds manufacturers to a high standard. It creates a level playing field where all certified products must meet the same minimum performance criteria, guaranteeing a consistent level of quality.

Common Pitfalls to Avoid

While the standards system is robust, misinterpreting its role can lead to safety gaps. Understanding its limitations is just as important as understanding its strengths.

A Standard is a Minimum, Not a Maximum

Certification means the footwear meets the minimum requirements for a specific hazard. It is the starting point for safety, not the end. Some work environments may require protection far exceeding the baseline standard.

Mismatching Protection to the Hazard

Assuming any safety shoe is suitable for any hazardous job is a dangerous mistake. A boot certified for impact and compression offers no protection from electrical shock unless it is also explicitly rated for that hazard. Always match the codes on the label to the specific risks of your workplace.

Making the Right Choice for Your Goal

Use your understanding of this system to select the right footwear with confidence.

- If your primary focus is compliance: Look for the permanent ASTM label inside the shoe to ensure it meets OSHA requirements.

- If your primary focus is specific hazard protection: Decode the label's specific lines to match the shoe's capabilities (e.g., EH for Electrical Hazard, PR for Puncture Resistance) to your exact workplace risks.

- If your primary focus is quality assurance: Trust footwear that has been tested and certified by an independent lab according to the full ASTM F2412 and F2413 standards.

By understanding how performance, testing, and labeling work together, you can ensure your protective footwear provides proven safety.

Summary Table:

| Aspect | Key Standard | Purpose |

|---|---|---|

| Performance Specifications | ASTM F2413 | Defines minimum requirements for impact, compression, etc. |

| Rigorous Testing | ASTM F2412 | Ensures unbiased verification by independent labs. |

| Standardized Labeling | OSHA Mandate | Provides clear identification of protections for compliance. |

Need certified protective footwear that meets all standards?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-compliant safety shoes and boots for distributors, brand owners, and bulk clients. We ensure every pair meets the rigorous demands of performance, testing, and labeling for guaranteed worker safety and OSHA compliance.

Contact us today for reliable, high-quality protective footwear solutions tailored to your specific hazards and needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- Why are professional protective footwear items essential for urban safety? The Ultimate Guide to Stability & Protection

- What role does protective footwear play in the comprehensive safety protocol for a natural stone production line? Essential Multi-Hazard Protection & Operational Continuity

- Why is puncture resistance required on job sites? Essential Protection Against Sharp Hazards

- What does the ASTM F2413-18 standard cover for safety footwear? A Guide to Workplace Toe Protection

- What are the disadvantages of using fabrics in safety shoe uppers? Balancing Comfort with Durability

- What are the key traits of good safety footwear? Protect Your Workforce with Durable, All-Day Comfort

- What protective functions do industrial safety shoes provide during material handling and lifting? Essential Foot Safety

- How does the application of lubricants assist in evaluating safety shoe performance? Master Slip Resistance Standards