At their core, OSHA-compliant safety shoes must undergo rigorous independent testing to meet specific ASTM standards for impact, compression, and other hazard-specific protections. This ensures footwear can withstand defined forces and environmental risks found in the workplace. The key is that OSHA doesn't test the shoes itself; it mandates compliance with established industry standards.

The central issue isn't just a simple checklist of tests. It's understanding that OSHA's requirement points to a broader standard, ASTM F2413, which is the true technical benchmark for performance against specific, quantifiable workplace hazards.

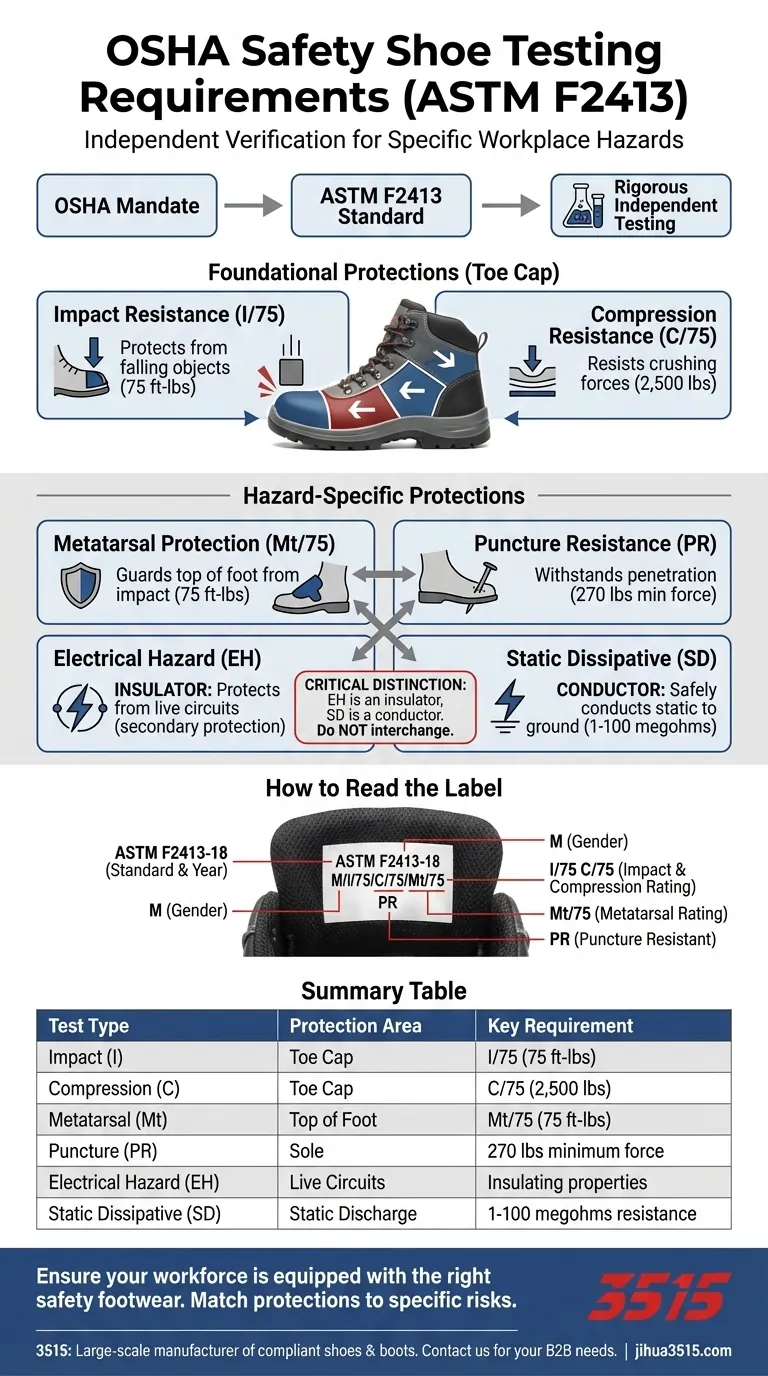

Deconstructing the Required Safety Tests

To be considered protective footwear under OSHA regulations, a shoe must meet the criteria outlined in the ASTM F2413 standard. This standard details the specific performance requirements for various protective features, which are verified through independent laboratory testing.

The Foundational Protections: Impact and Compression

The most fundamental requirements for any safety toe shoe are its resistance to impact and compression. These tests ensure the toe cap can protect the wearer from falling objects and crushing forces.

- Impact Resistance (I): This test measures the toe cap's ability to withstand a heavy object falling on it. A weight is dropped from a specified height, and the clearance inside the toe cap is measured.

- Compression Resistance (C): This test assesses the toe cap's ability to resist crushing forces, such as from a vehicle wheel. The shoe is subjected to a slow, heavy load, and the internal clearance is again measured.

- Rating System: Shoes are rated based on the level of protection, with a "75" rating (e.g., I/75, C/75) being the highest, indicating protection against 75 foot-pounds of impact and 2,500 pounds of compression.

Hazard-Specific Protections

Beyond the basic toe cap, ASTM F2413 outlines testing for a variety of specialized hazards. A shoe only needs to meet the standards for the specific risks it is designed to protect against.

- Metatarsal Protection (Mt): This feature guards the top of the foot (the metatarsal bones) against impact. The rating, such as "Mt/75," corresponds to the impact energy it can withstand.

- Puncture Resistance (PR): This applies to shoes with a puncture-resistant plate in the sole. The test measures the force required to penetrate the plate, with the standard requiring it to withstand a minimum of 270 pounds of force.

- Electrical Hazard (EH): EH-rated footwear is designed to protect the wearer from open electrical circuits. The soles are tested to provide a secondary source of protection by impeding the flow of electricity through the shoe and to the ground.

- Static Dissipative (SD): These shoes are tested for their ability to safely conduct static electricity to the ground, reducing the risk of static discharge. The test measures electrical resistance, which must fall within a specific range (typically 1 to 100 megohms).

Understanding the Trade-offs and Markings

Not all safety shoes are created equal, and choosing the wrong type can introduce new risks. Understanding the markings and inherent limitations is critical for true compliance and safety.

Why One Shoe Doesn't Fit All Hazards

A common mistake is assuming one high-quality safety shoe covers all potential risks. An Electrical Hazard (EH) shoe is built to be an insulator, while a Static Dissipative (SD) shoe is designed to be a conductor. Using one where the other is required can have catastrophic consequences.

How to Read the Label

Every ASTM-compliant safety shoe has a label (usually on the tongue) that clearly states its specific protections. A typical label might read: ASTM F2413-18 M/I/75/C/75/Mt/75 PR.

- ASTM F2413-18: Identifies the standard and the year it was issued.

- M/I/75: Specifies it's for a Male (M), meets Impact resistance level 75.

- C/75: Meets Compression resistance level 75.

- Mt/75: Meets Metatarsal protection level 75.

- PR: Indicates the shoe is Puncture Resistant.

By reading this label, you can instantly verify if the shoe's tested protections align with the hazards present in your specific work environment.

Making the Right Choice for Your Goal

To ensure compliance and worker safety, you must match the footwear's tested capabilities to the specific risks identified in your workplace hazard assessment.

- If your primary focus is protection from falling objects and heavy equipment: Ensure all footwear carries the I/75 and C/75 rating for maximum impact and compression resistance.

- If your primary focus is working near live electrical circuits: You must select footwear specifically marked with the "EH" rating.

- If your primary focus is preventing static discharge in sensitive environments: Mandate footwear that is clearly tested and marked as "SD" (Static Dissipative).

- If your primary focus is protection from sharp objects underfoot: The shoe must have the "PR" designation, indicating it has passed the puncture resistance test.

Ultimately, selecting the correct safety footwear is a critical engineering control that moves beyond simple compliance to active, targeted risk prevention.

Summary Table:

| Test Type | Protection | Key Rating/Requirement |

|---|---|---|

| Impact (I) | Toe Cap | I/75 (75 ft-lbs) |

| Compression (C) | Toe Cap | C/75 (2,500 lbs) |

| Metatarsal (Mt) | Top of Foot | Mt/75 (75 ft-lbs) |

| Puncture (PR) | Sole | 270 lbs minimum force |

| Electrical Hazard (EH) | Live Circuits | Insulating properties |

| Static Dissipative (SD) | Static Discharge | 1-100 megohms resistance |

Ensure your workforce is equipped with the right safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM F2413-compliant shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, ensuring you get precisely the right protection for your specific workplace hazards. Contact us today to discuss your safety shoe needs and receive a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.