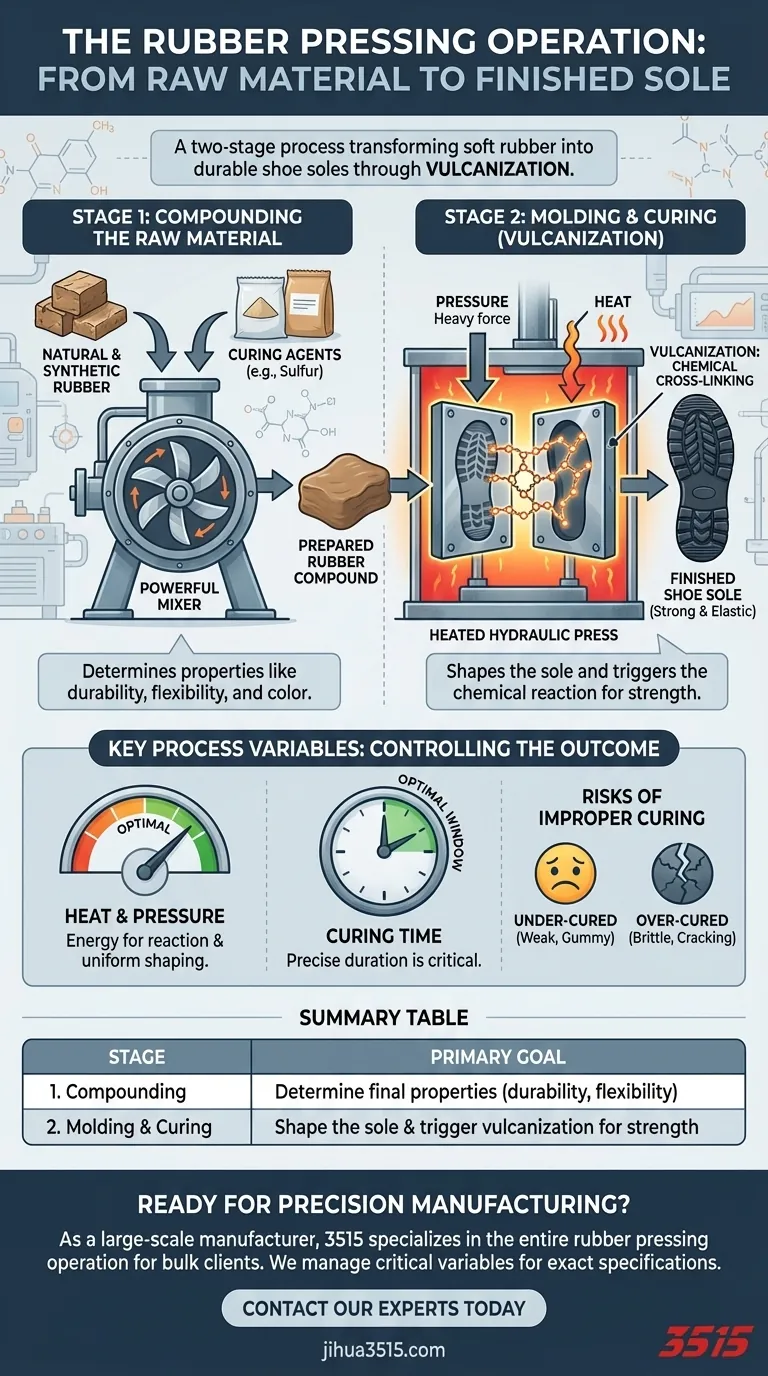

At its core, the rubber pressing operation for shoe soles is a two-stage process. First, raw rubber components are meticulously mixed together, and second, this compound is placed into a mold where heat and pressure are applied to permanently shape and strengthen it into a finished sole.

The entire operation is designed to achieve one critical outcome: transforming a soft, pliable rubber mixture into a durable, elastic, and perfectly formed shoe sole through a chemical process known as vulcanization.

The Two Foundational Stages of Sole Pressing

The production of a rubber sole is not merely a matter of shaping; it's a fundamental chemical transformation. Each stage serves a distinct and vital purpose in creating the final product's characteristics.

Stage 1: Compounding the Raw Material

Before any heat or pressure is applied, the base rubber must be prepared. This is the stage where the final sole's properties like durability, flexibility, and color are determined.

The process involves mixing base rubbers, which can be natural rubber, synthetic rubbers, or a blend of both, in powerful mixers.

To this base, crucial curing agents are added. These are typically sulfur or peroxide-based compounds that act as the catalyst for the chemical reaction in the next stage.

Stage 2: Molding and Curing (Vulcanization)

This is where the mixture takes its final shape and gains its strength. The prepared rubber compound is placed into a precisely machined mold, which is then set into a large heated hydraulic press.

The press serves two functions simultaneously. It applies immense pressure to ensure the rubber fills every detail of the mold, forming the tread and overall shape.

At the same time, it applies high heat, which initiates the curing process. The heat activates the curing agents (like sulfur), causing them to create chemical cross-links between the long polymer chains of the rubber.

This chemical reaction, known as vulcanization, is what converts the soft, weak rubber compound into a strong, stable, and elastic material suitable for a shoe sole.

Understanding the Key Process Variables

The success of the rubber pressing operation hinges on controlling a few critical factors. A failure to manage these variables results in a sole that is either weak and gummy or brittle and prone to cracking.

The Role of Heat and Pressure

Heat provides the necessary energy to kickstart the vulcanization reaction. Without sufficient heat, the sole will be under-cured and lack durability.

Pressure ensures the rubber compound maintains intimate contact with the heated mold surface, allowing for uniform heat transfer and preventing air bubbles or imperfections in the final shape.

The Importance of Curing Time

The duration for which the sole is held under heat and pressure is critical. There is a precise window for optimal curing.

An under-cured sole will not have formed enough chemical cross-links, resulting in a weak product that wears out quickly. Conversely, an over-cured sole can become too rigid and brittle, losing its necessary flexibility.

Applying This Knowledge to Your Goal

Understanding this process allows you to make more informed decisions, whether in design, material specification, or quality assessment.

- If your primary focus is on performance and durability: Pay close attention to the initial compounding stage, as the specific blend of rubbers and curing agents dictates the final material properties.

- If your primary focus is on aesthetic design and tread: The precision and quality of the mold are paramount, as it is the sole determinant of the final shape and surface detail.

- If your primary focus is on manufacturing quality control: The consistent application of heat, pressure, and time during the curing stage is the most critical factor to monitor.

Ultimately, mastering the interplay between material science in compounding and process control in molding is the key to producing a high-quality rubber shoe sole.

Summary Table:

| Stage | Key Process | Primary Goal |

|---|---|---|

| 1. Compounding | Mixing base rubbers with curing agents (e.g., sulfur) | Determine final properties like durability and flexibility |

| 2. Molding & Curing | Applying heat and pressure in a hydraulic press | Shape the sole and trigger vulcanization for strength and elasticity |

Ready to produce high-quality rubber soles with precision?

As a large-scale manufacturer, 3515 specializes in the entire rubber pressing operation for distributors, brand owners, and bulk clients. We manage the critical variables—from material compounding to precise vulcanization—ensuring your soles meet exact specifications for performance, design, and durability.

Our production capabilities encompass all types of shoes and boots. Contact our experts today to discuss your sole manufacturing needs and leverage our expertise for your next project.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

- Durable Moc-Toe Wedge Work Boots | Wholesale Manufacturing for Brands

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- What are the advantages of rubber in footwear? Unlock Superior Durability, Grip & Comfort

- How does the flexibility of rubber soles compare to TPR soles? Key Differences Explained

- Why are rubber-soled shoes considered multi-weather footwear? Unlock All-Season Traction & Protection

- What factors determine the slip resistance of rubber-soled shoes? Tread, Compound & Design Explained

- Why is high-grade rubber used in slip-resistant shoe soles? For Superior Traction on Slippery Surfaces

- What is rubber and how is it produced? From Tree Sap to Durable Footwear

- How are shoes with vulcanized soles manufactured? Discover the Process Behind Durable Footwear

- What is the importance of slip-resistant outsoles in preventing Lower Back Pain? Stabilize Your Spine with Every Step