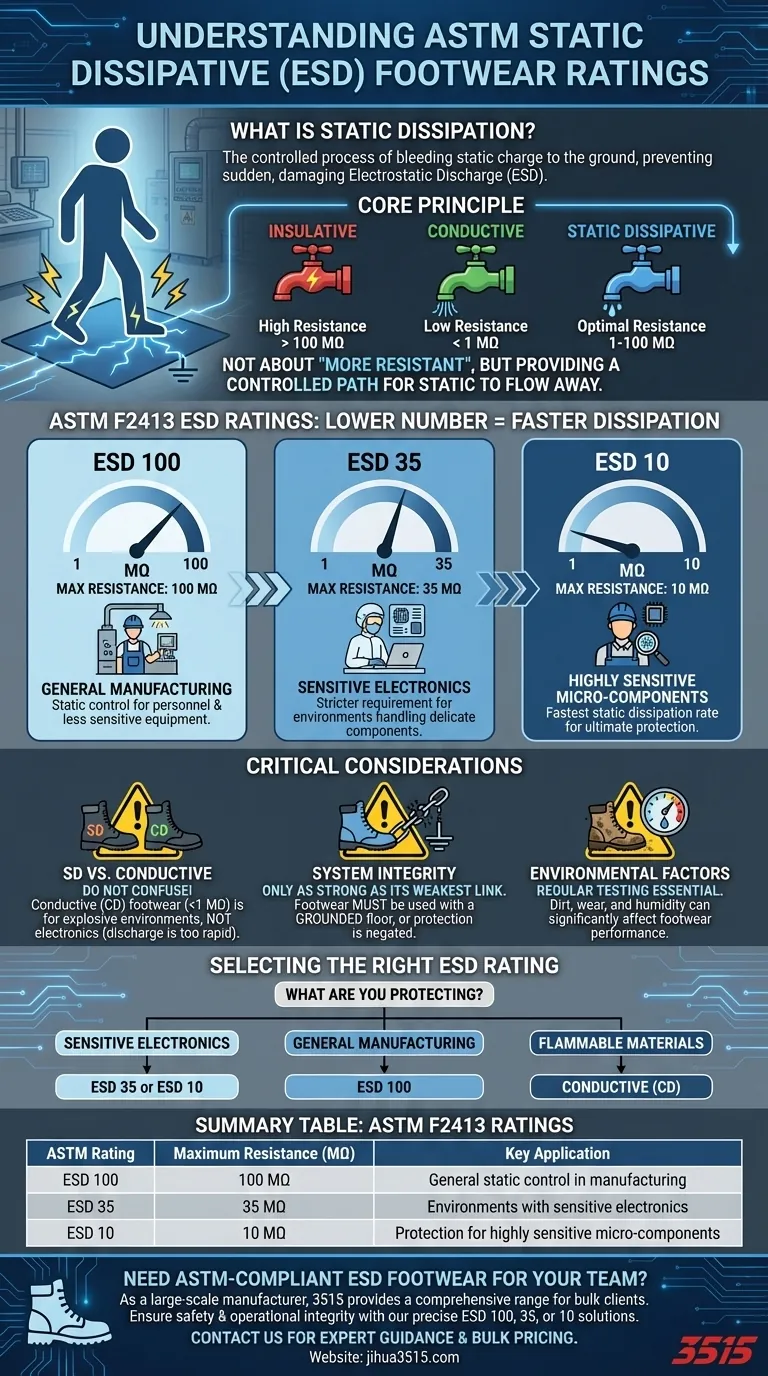

In short, ASTM static dissipative standards define three primary ratings: ESD 100, ESD 35, and ESD 10. These numbers represent the maximum allowable electrical resistance of the footwear in megohms (MΩ). A lower number signifies lower resistance, which allows static electricity to dissipate to the ground more quickly and in a more controlled manner.

The core principle to understand is that these ratings are not about being "more resistant to static" but about providing a controlled path for static charges to flow away from your body. The specific rating you need depends entirely on the sensitivity of the components you are handling or the volatility of your environment.

What "Static Dissipative" Really Means

Defining Static Dissipation

Static dissipation is the controlled process of bleeding a static charge from a person or object to the ground. It prevents the sudden, uncontrolled spark known as an Electrostatic Discharge (ESD).

This is critical in many industries where a random spark could damage sensitive electronics or ignite flammable materials.

The Critical Role of Resistance

The speed of this charge transfer is determined by electrical resistance, measured in Ohms.

Think of it like a faucet:

- Too high resistance (Insulative): The faucet is closed. Charge builds up with nowhere to go.

- Too low resistance (Conductive): The faucet is wide open. Charge rushes out, creating a potentially damaging spark.

- Just right (Static Dissipative): The faucet is open just enough. Charge flows away steadily and safely without a spark.

How ASTM Measures Performance

The ASTM F2413 standard outlines the test methods and performance requirements for protective footwear. For Static Dissipative (SD) properties, footwear must fall within a resistance range of 1 to 100 megohms (1x10⁶ to 1x10⁸ Ohms).

The specific ESD ratings (100, 35, 10) are used to classify footwear within this broader SD category, indicating different levels of performance for more demanding applications.

Decoding the ASTM ESD Ratings

The Three Standard Levels

While all fall under the general ASTM F2413 standard for SD footwear, these ratings provide a more granular classification.

- SD 100 (or ESD 100): This requires the footwear's resistance to be between 1 and 100 megohms. It is the general standard for most static dissipative applications.

- SD 35 (or ESD 35): This is a stricter requirement, mandating a resistance between 1 and 35 megohms. This is often required for environments with more sensitive electronics.

- SD 10 (or ESD 10): This is the most stringent classification, requiring resistance between 1 and 10 megohms. It provides the fastest rate of static dissipation for protecting highly sensitive micro-components.

Lower Number = Faster Dissipation

It is crucial to understand this relationship: the lower the number, the lower the electrical resistance.

A lower resistance means static charge can flow to the ground more easily and quickly. Therefore, an ESD 10 boot dissipates static faster than an ESD 100 boot.

Common Pitfalls and Considerations

Static Dissipative vs. Conductive Footwear

Do not confuse Static Dissipative (SD) with Conductive (CD) footwear.

Conductive footwear has an extremely low electrical resistance (less than 1 megohm). It is designed for environments with explosive or volatile materials where a static spark of any kind must be prevented at all costs. It is generally not suitable for protecting electronics, as the discharge is too rapid.

The System is Only as Strong as its Weakest Link

ESD footwear is useless without a proper grounding path. The footwear must be used in conjunction with a static dissipative or conductive floor.

Without a grounded floor, the static charge has nowhere to go, and the protective properties of the footwear are completely negated.

Environmental Factors Matter

The performance of ESD footwear can be affected by several factors. A dirty or worn-out sole can increase resistance, while high humidity can decrease it. Regular testing is essential to ensure continued compliance.

How to Select the Correct ESD Rating

Choosing the right footwear is a critical safety decision based on your specific work environment and the sensitivity of the materials you handle.

- If your primary focus is protecting sensitive electronic components: You need a rapid, controlled dissipation path. An SD 35 or SD 10 rating is often specified for these environments.

- If your goal is general static control in manufacturing: An SD 100 rating typically provides sufficient protection to prevent static build-up on personnel and protect less sensitive equipment.

- If you work with highly flammable or explosive materials: You likely need Conductive (CD) footwear, not Static Dissipative (SD), to ensure the fastest possible path to ground. Always defer to your organization's specific safety protocols.

Ultimately, understanding these ratings empowers you to select the precise level of protection required to ensure both safety and operational integrity.

Summary Table:

| ASTM Rating | Maximum Resistance (MΩ) | Key Application |

|---|---|---|

| ESD 100 | 100 MΩ | General static control in manufacturing |

| ESD 35 | 35 MΩ | Environments with sensitive electronics |

| ESD 10 | 10 MΩ | Protection for highly sensitive micro-components |

Need the right static dissipative footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-compliant ESD footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure you get the precise level of static dissipation (ESD 100, 35, or 10) required for your specific safety protocols and operational integrity.

Contact us today for expert guidance and bulk pricing on reliable static control footwear.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- What are the properties of suede as a material for men's boots? Unlocking Style, Softness, and Care

- What additional safety features do structural firefighting boots provide? Beyond Heat Resistance

- What are the key characteristics of PVC work boots? Uncover Their Waterproof, Lightweight & Affordable Benefits

- What key functions do industrial safety boots with all-weather protection provide? Maximize Outdoor Operational Output

- When and by whom were engineer boots first produced? Discover the Origins of an Industrial Icon

- Are zippers common in cowboy boots? The Truth About Authentic vs. Modern Western Boots

- What are the advantages of using Rubber for work boots? Unbeatable Safety & Durability

- What problems can occur with frozen boots in winter cycling? Avoid Painful Blisters and Cold Feet