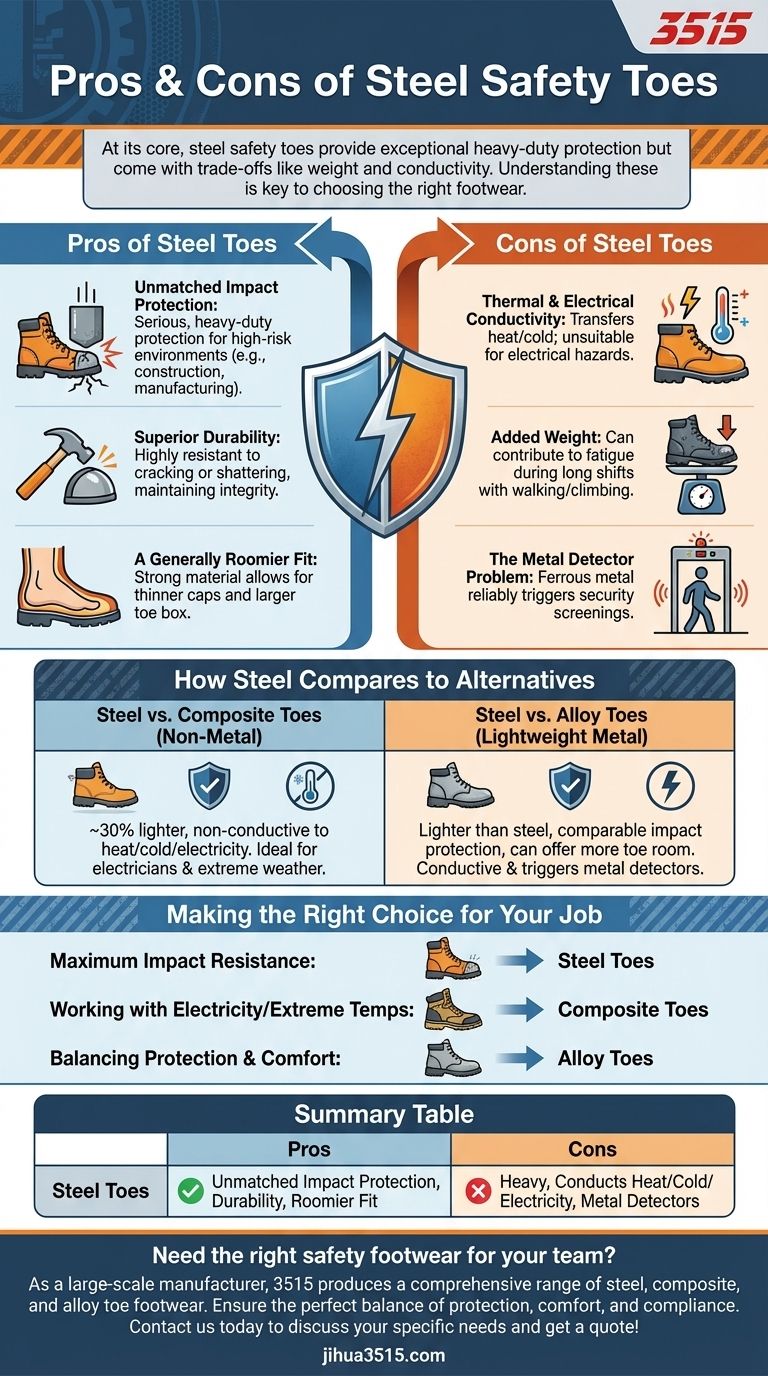

At its core, a steel safety toe provides exceptional protection against heavy impacts and is highly resistant to cracking. However, its primary drawbacks are its weight, its tendency to conduct heat and electricity, and the fact that it will trigger metal detectors.

While steel toes represent the traditional standard for heavy-duty protection, understanding their specific trade-offs against modern alternatives like composite and alloy is essential for choosing the right safety footwear for your specific work environment.

The Defining Strengths of Steel Toes

Steel has long been the benchmark for safety toes for a reason. Its inherent properties make it ideal for environments where the risk of crushing or impact is highest.

Unmatched Impact Protection

Steel safety toes are the most common type and provide serious, heavy-duty protection. Their fundamental strength makes them a reliable choice for industries like construction and manufacturing.

Superior Durability

The material itself is incredibly durable. Steel is highly resistant to cracking or shattering upon impact, ensuring the protective cap maintains its integrity when you need it most.

A Generally Roomier Fit

Because steel is so strong, the protective cap can be made relatively thin. This often results in a larger toe box, providing more room and comfort for the wearer's toes.

Understanding the Trade-offs

No single material is perfect for every situation. The very properties that make steel strong also create specific limitations you must consider.

Thermal and Electrical Conductivity

Steel is an excellent conductor. This means it transfers both heat and cold efficiently, making steel-toed boots potentially uncomfortable in extreme temperatures. More importantly, this conductivity makes them unsuitable for roles with electrical hazards.

Added Weight

Compared to more modern alternatives, steel is heavy. While durable, this added weight can contribute to fatigue, especially when worn for long shifts that involve a lot of walking or climbing.

The Metal Detector Problem

As a ferrous metal, steel will reliably set off metal detectors. This can be a significant inconvenience in secure facilities that require frequent screening.

How Steel Compares to the Alternatives

To make an informed decision, you must see how steel stacks up against other common safety toe materials. Each is engineered to solve a different set of problems.

Steel vs. Composite Toes

Composite safety toes are made from non-metal materials like carbon fiber, plastic, or Kevlar. Their key advantage is being approximately 30% lighter than steel.

Because they are non-metallic, they do not conduct heat, cold, or electricity, making them the superior choice for electricians or those working in extreme weather conditions.

Steel vs. Alloy Toes

Alloy safety toes are made from a mixture of lightweight metals, such as aluminum or titanium. They offer impact protection comparable to steel but at a significantly lower weight.

Alloy toes are often more comfortable for long shifts and can provide even more toe room than some steel cap designs. However, like steel, they are conductive and will set off metal detectors.

Making the Right Choice for Your Job

Your specific work environment and daily tasks should be the deciding factor.

- If your primary focus is maximum impact resistance: Steel toes offer the traditional, time-tested standard for heavy-duty protection in high-risk environments.

- If your primary focus is working with electricity or in extreme temperatures: Composite toes are the only logical choice due to their non-conductive properties.

- If your primary focus is balancing protection with all-day comfort: Alloy toes provide a lightweight alternative to steel without significantly compromising on impact resistance.

Ultimately, selecting the right safety toe is about matching the material's properties to your personal safety needs.

Summary Table:

| Pros of Steel Toes | Cons of Steel Toes |

|---|---|

| Unmatched impact protection | Heavy, can cause fatigue |

| Superior durability, resists cracking | Conducts heat and cold |

| Generally roomier fit for comfort | Conducts electricity (electrical hazard) |

| Industry standard for heavy-duty work | Will set off metal detectors |

Need the right safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear with steel, composite, and alloy toes for distributors, brand owners, and bulk clients. Our production capabilities ensure you get the perfect balance of protection, comfort, and compliance for any work environment.

Contact us today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What are the advantages of wearing steel toe shoes? Maximum Protection for Your Workforce

- How can you keep steel toe boots dry? A Practical Guide to All-Day Foot Comfort

- What home remedies can help relieve sore feet from steel toe boots? Soothe Aches & Prevent Pain

- What are the key properties of steel that make it suitable for toe caps? Maximum Protection & Durability

- How do safety toes and steel toes compare? Choose the right protection for mobility or durability.

- Why is it important to wear steel toe work boots? Maximum Impact Protection for Hazardous Work

- What are the characteristics of a properly fitting steel toe boot? Achieve All-Day Safety and Comfort

- How do aluminum toe boots compare to steel toe boots? Achieve Lighter Weight with Equal Protection