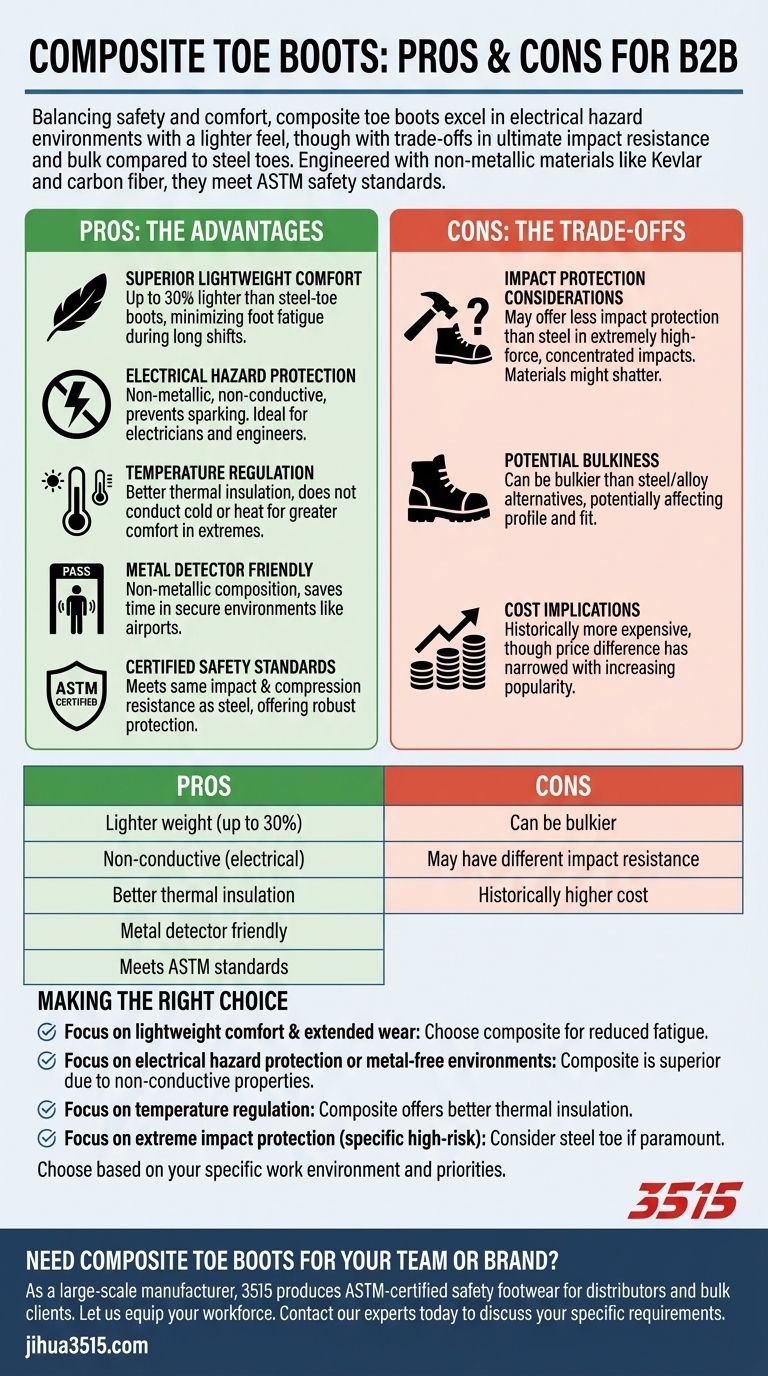

Composite toe boots offer a balance of safety and comfort, excelling in electrical hazard environments and providing a lighter feel, though they may have specific trade-offs in ultimate impact resistance and bulk compared to steel-toe alternatives. These boots are engineered with non-metallic materials like Kevlar, carbon fiber, or plastic, meeting the same ASTM safety standards for impact and compression as other safety footwear types. Their distinct composition provides several unique benefits, making them a preferred choice in various professional settings.

Composite toe boots provide ASTM-certified foot protection that is lighter, non-conductive, and temperature-resistant, making them ideal for specific environments like those with metal detectors or electrical risks. However, they can be bulkier and may offer slightly different impact resistance profiles compared to steel toes, necessitating a careful evaluation of work requirements.

The Advantages of Composite Toe Boots

Composite toe boots are favored for several key benefits directly related to their construction.

Superior Lightweight Comfort

A primary advantage of composite toe boots is their significantly lighter weight. They can be up to 30 percent lighter than steel-toe boots. This reduction in weight helps minimize foot fatigue, especially during long shifts or for workers who spend extensive time on their feet.

Electrical Hazard Protection

Made from non-metallic materials, composite toe boots do not conduct electricity. This makes them an excellent choice for electricians, engineers, and anyone working in environments with potential electrical hazards. They are metal-free and prevent sparking.

Temperature Regulation

Composite toes offer better thermal insulation compared to their metal counterparts. They do not conduct cold in winter or heat in summer, providing greater comfort in extreme temperatures. This temperature insensitivity is beneficial for workers in outdoor environments.

Metal Detector Friendly

Their non-metallic composition means composite toe boots will not set off metal detectors. This is a significant advantage for airport security, manufacturing facilities, or other settings requiring frequent passage through metal detection. It saves time and hassle.

Certified Safety Standards

Despite being lighter and non-metallic, composite toe boots are ASTM certified. They meet the same impact and compression resistance requirements as steel toe boots, offering high-level foot protection against crush, cut, and puncture hazards. This ensures robust safety without the weight of metal.

Understanding the Trade-offs

While offering many benefits, composite toe boots also come with specific characteristics that users should consider.

Impact Protection Considerations

Although they meet safety standards, some sources suggest that composite toes may offer less impact protection than steel toes in extremely high-force, concentrated impacts. Steel can deform but maintain integrity, whereas composite materials might shatter. However, both types meet the same base safety certifications.

Potential Bulkiness

Due to the nature of the materials required to meet safety standards without metal, composite toe boots can sometimes be bulkier than steel or alloy toe alternatives. This might affect the overall profile and fit of the boot.

Cost Implications

Historically, composite toe boots were often more expensive than steel toe boots. While their increasing popularity and production have made them more affordable, they can still represent a higher initial investment in some cases. This cost difference has narrowed considerably.

Material Composition

The choice of materials is central to the performance of composite toe boots.

Non-Metallic Construction

Composite toes are crafted from advanced non-metallic materials. Common examples include Kevlar, carbon fiber, plastic, or fiberglass. These materials are chosen for their strength-to-weight ratio and non-conductive properties.

Making the Right Choice for Your Goal

Selecting the ideal safety boot depends on your specific work environment and priorities.

- If your primary focus is lightweight comfort and extended wear: Opt for composite toe boots to reduce fatigue over long shifts.

- If your primary focus is electrical hazard protection or metal-free environments: Composite toe boots are the superior choice due to their non-conductive and metal detector-friendly properties.

- If your primary focus is extreme impact protection in very specific, high-risk scenarios: While composite meets standards, consider steel toe if the absolute highest, most concentrated impact resistance is paramount to your specific hazard assessment.

- If your primary focus is temperature regulation and comfort in varied climates: Composite toes offer better thermal insulation, making them comfortable in both hot and cold conditions.

By understanding these nuances, you can confidently choose the safety footwear that best meets your professional demands.

Summary Table:

| Pros | Cons |

|---|---|

| Lighter weight (up to 30% lighter than steel) | Can be bulkier than steel toe alternatives |

| Non-conductive; ideal for electrical hazards | May offer slightly different impact resistance in extreme scenarios |

| Better thermal insulation (no heat/cold transfer) | Historically higher cost, though price gap is narrowing |

| Will not set off metal detectors | |

| Meets ASTM impact/compression safety standards |

Need Composite Toe Boots for Your Team or Brand?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified safety footwear for distributors, brand owners, and bulk clients. We can deliver high-quality composite toe boots that combine lightweight comfort with reliable protection.

Let us help you equip your workforce with the right safety gear. Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Durable Leather Safety Boots for Wholesale & Custom OEM Manufacturing

People Also Ask

- What is the lightest type of safety-toe boot available? The Ultimate Guide to Alloy Toes

- What are the changes to slip resistance markings in EN ISO 20345:2022? A Guide to the New SR Marking

- What is the best fit for security guard safety boots? A Guide to Comfort, Safety, and Durability

- Why is comfort important in safety toe boots? Boost Worker Safety and Productivity

- Why should composite safety shoes be replaced after a significant impact? The Invisible Danger Explained

- What protective function do slip-resistant safety shoes provide in confined spaces? Maximize Stability & Grip

- What is the most common shoe width for safety toe boots? The Critical Fit Guide for Comfort & Safety

- What are the advantages of using an active buzzer and vibration motor in smart shoes? Enhance Safety with Dual Alerts