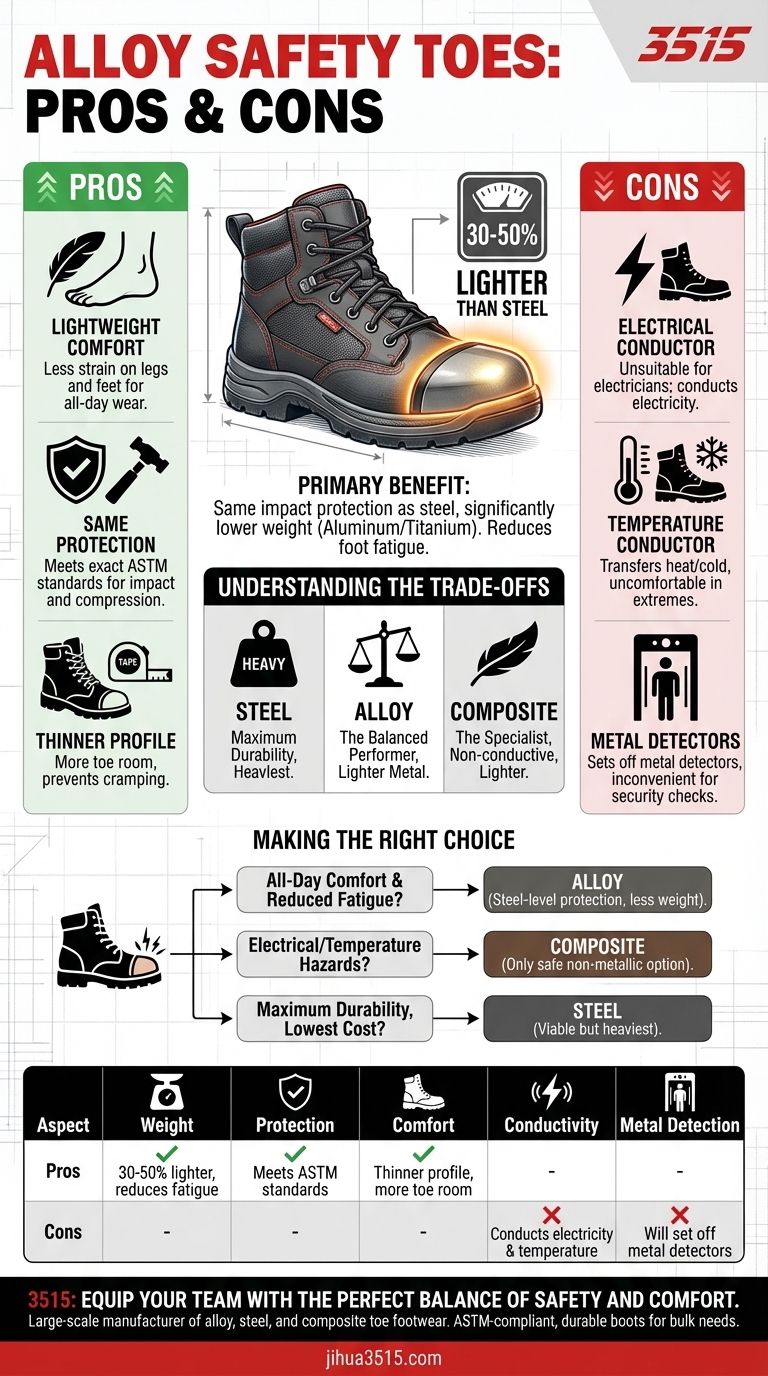

The primary benefit of an alloy safety toe is that it provides the same impact protection as a traditional steel toe but at a significantly lower weight. Made from materials like aluminum and titanium, alloy toes are 30-50% lighter than steel, which reduces foot fatigue over long shifts. The main drawbacks are that they conduct electricity and temperature and will set off metal detectors.

Alloy safety toes represent a modern balance, offering the robust protection of steel in a much lighter and more comfortable package. The key is understanding if your specific work environment introduces hazards like electricity or extreme temperatures where a non-metallic option is required.

Protection vs. Comfort: The Core Comparison

When choosing a safety boot, the decision often comes down to a balance between protection level, weight, and comfort. Alloy toes were developed to optimize this balance, directly competing with traditional steel and modern composite options.

How Alloy Compares in Impact Resistance

Alloy safety toes are engineered to meet the exact same ASTM safety standards for impact and compression as steel toes.

They provide exceptional protection against falling objects and crushing forces, making them suitable for demanding environments like construction sites and warehouses.

The Advantage of Lighter Weight

The most significant advantage of alloy is its reduced weight. Being 30-50% lighter than steel, it dramatically lessens the strain on your legs and feet.

This reduction in fatigue is a critical factor for anyone who spends their entire day standing, walking, or climbing.

The Benefit of a Thinner Profile

Because alloy metals are strong, the protective toe cap can be made with a thinner profile than a steel cap.

This translates directly to more room in the toe box, providing a more comfortable fit and preventing your toes from feeling cramped.

Key Environmental and Jobsite Considerations

While alloy toes excel in protection and comfort, they share some of the same limitations as steel. These environmental factors are often the deciding factor when choosing between alloy and a composite alternative.

Electrical Hazards

Like any metal, alloy is a conductor of electricity. This makes alloy-toe boots unsuitable for electricians or anyone working in an environment with a risk of live electrical currents.

For these roles, a non-metallic composite toe is the only safe option.

Extreme Temperatures

Alloy also conducts heat and cold. In very hot or freezing conditions, the temperature can transfer through the toe cap to your foot, causing significant discomfort.

Composite toes do not conduct temperature, making them a superior choice for working in extreme weather.

Metal Detectors

If your job requires you to pass through metal detectors frequently, alloy-toe boots will be a constant inconvenience.

Workers in security-sensitive fields like aviation, corrections, or secure facilities often choose composite toes to avoid this issue.

Understanding the Trade-offs

No single safety toe is perfect for every situation. The choice between steel, alloy, and composite is a matter of prioritizing the needs of your specific job.

Steel: Maximum Durability

Steel remains a popular choice for its proven track record and sheer toughness. It offers immense protection but at the cost of being the heaviest option.

Alloy: The Balanced Performer

Alloy provides the best of both worlds: the proven strength of metal with a significant weight reduction. It is the ideal general-purpose choice unless specific environmental hazards are present.

Composite: The Specialist

Composite toes are made from non-metallic materials like carbon fiber, Kevlar, or plastic. They are lighter than steel and do not conduct electricity or temperature, making them a specialized solution for specific hazards. Their primary trade-off is that they may not offer the same level of impact resistance as metal after an initial major impact.

Making the Right Choice for Your Work

To select the right boot, align its features with the primary demands of your workday.

- If your primary focus is all-day comfort and reduced fatigue: Alloy is an excellent choice, offering steel-level protection without the weight.

- If your primary focus is working around electrical or temperature hazards: Composite is the only appropriate and safe option for your needs.

- If your primary focus is maximum durability at the lowest cost: Steel remains a viable, traditional option, but be prepared for the extra weight.

Ultimately, choosing the right safety toe is about matching the material's properties to your daily risks and comfort needs.

Summary Table:

| Aspect | Pros | Cons |

|---|---|---|

| Weight | 30-50% lighter than steel, reduces fatigue | - |

| Protection | Meets ASTM standards for impact/compression | - |

| Comfort | Thinner profile for more toe room | - |

| Conductivity | - | Conducts electricity and temperature |

| Metal Detection | - | Will set off metal detectors |

Equip your team with the perfect balance of safety and comfort. As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear with alloy, steel, and composite toes for distributors, brand owners, and bulk clients. Our production capabilities ensure you get durable, ASTM-compliant boots tailored to your specific job site hazards. Contact our experts today to discuss your bulk safety footwear needs and request a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- What standard governs safety footwear requirements? A Guide to OSHA & EN ISO 20345

- What additional features can safety shoes have? Advanced Protection for Your Specific Work Hazards

- What types of burn hazards can safety shoes protect against? Essential Footwear for High-Risk Workplaces

- Are composite toe boots corrosion resistant? Yes, and Here’s Why They Excel

- How is the sole attached to the upper in safety shoes manufacturing? Choose the Right Bond for Durability

- Why is high-quality protective footwear considered a vital component of road safety? Maximize Stability & Recovery

- What factors should be considered when choosing the appropriate type of safety footwear? A Guide to Maximum Protection

- How common are occupational foot injuries? 100,000 Annual Cases Signal a Major Productivity Risk