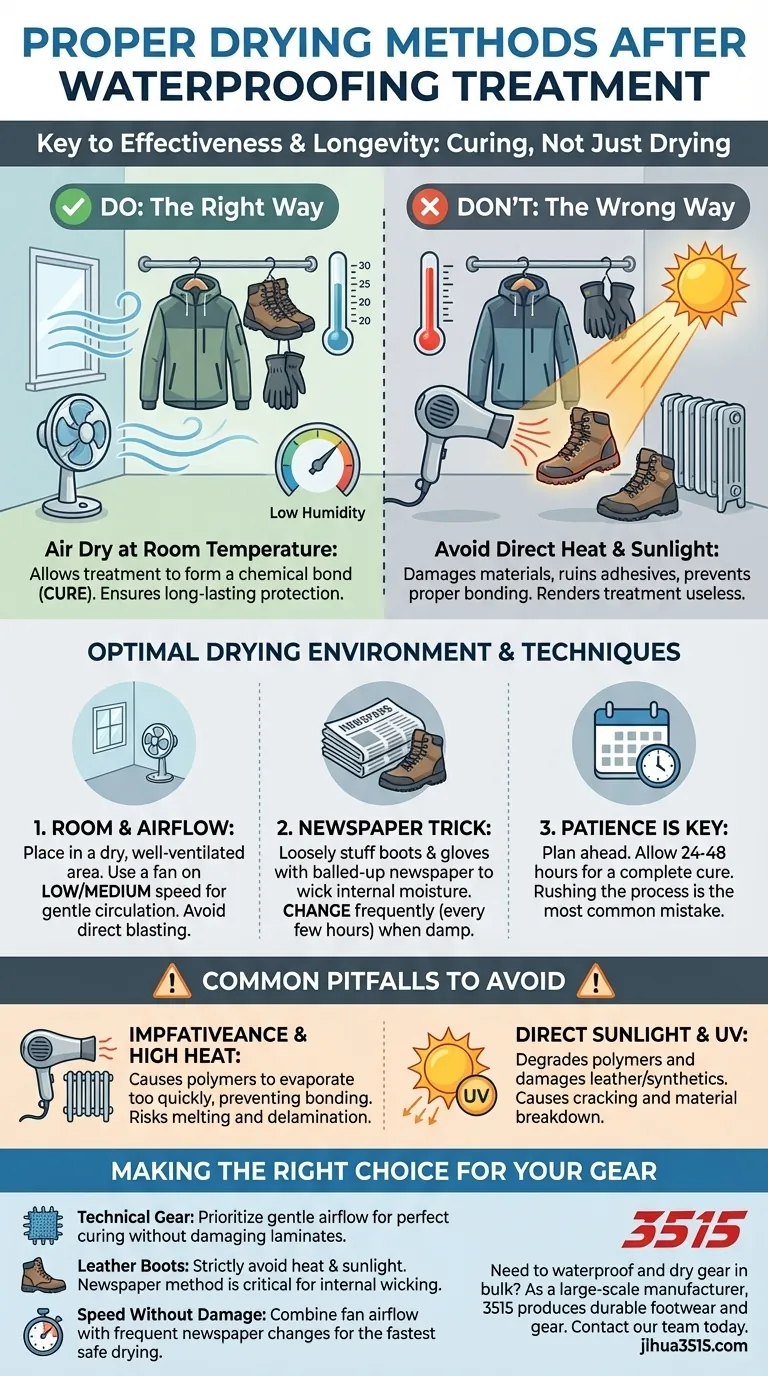

The most effective way to dry your gear after applying a waterproofing treatment is to let it air dry at a normal room temperature, in a well-ventilated area with low humidity. Critically, you must avoid using any direct heat sources, like a hairdryer or fireplace, as this can damage both the gear and the treatment you just applied.

Proper drying is less about speed and more about creating the right environment for the waterproofing to cure effectively. Rushing the process with high heat is the single most common mistake, and it can permanently damage your gear's materials and compromise the treatment's bond.

Why a Gentle Drying Process is Non-Negotiable

Understanding the "why" behind the method ensures you get it right every time. The goal isn't just to remove moisture; it's to allow a chemical process to complete successfully.

The Goal: Curing, Not Just Drying

Waterproofing treatments don't just sit on the surface; they need to cure. This means they form a chemical bond with the fibers of the fabric or leather.

This bonding process takes time and happens best at a stable, moderate temperature. Gentle drying allows the carrier agents in the treatment to evaporate slowly, leaving the active waterproofing polymers behind to bond correctly.

The Dangers of High Heat

Applying direct heat is counterproductive and damaging. It can cause the waterproofing agents to evaporate before they can bond, rendering your application useless.

Worse, it can ruin your gear by melting adhesives, causing leather to crack and shrink, or causing synthetic fabrics and waterproof membranes (like GORE-TEX) to delaminate.

The Role of Airflow and Humidity

Good airflow is your best tool for safe and effective drying. A simple fan circulates the air, carrying away the evaporating moisture and solvents from the gear's surface.

Low humidity is equally important. If the surrounding air is already saturated with moisture, evaporation will slow to a crawl, unnecessarily prolonging the drying time.

How to Create the Optimal Drying Environment

You don't need special equipment, just a thoughtful setup.

Location is Key

Place your gear in a dry, well-ventilated room away from direct sunlight. A utility room, a garage, or a covered porch on a dry day are all excellent choices.

The key is to maintain a consistent, average room temperature.

Accelerate Drying with a Fan

Place a small fan a few feet away from your gear. Set it to a low or medium speed to circulate air around the items, not blast them directly.

This constant, gentle airflow is the safest way to speed up the evaporation process.

The Newspaper Trick for Internal Moisture

For boots and gloves, loosely stuffing them with balled-up newspaper is a classic and effective technique. The paper acts as a wick, drawing moisture out from the inside.

Be sure to change the newspaper every few hours, or as soon as it feels damp. This removes the absorbed moisture from the environment and allows the process to continue.

Understanding the Common Pitfalls

Avoiding these simple mistakes is just as important as following the right steps.

The Pitfall of Impatience

The most common mistake is trying to rush the process. Using a hairdryer, boot dryer with a heat element, or placing gear near a radiator or fire is a guaranteed way to risk damage.

Patience is a required part of the waterproofing process. Plan ahead and allow for adequate drying time—often 24 to 48 hours.

The Risk of Direct Sunlight

While it may seem like a natural heat source, direct sunlight should be avoided. The combination of intense, uneven heat and UV radiation can degrade the waterproofing polymers and damage the underlying materials, especially leather and certain synthetics.

Making the Right Choice for Your Gear

While the principles are universal, your primary goal may slightly adjust your focus.

- If your primary focus is maximum performance for technical gear: Prioritize steady, gentle airflow from a fan to ensure the treatment cures perfectly without damaging sensitive laminates and adhesives.

- If your primary focus is caring for leather boots: Avoid all forms of heat and sunlight, as they can cause the leather to dry out, stiffen, and crack. The newspaper method is especially critical for wicking moisture from the inside.

- If your primary focus is speed without damage: Combine a fan for external airflow with frequently changed newspaper on the inside. This two-pronged approach is the fastest and safest method available.

By patiently controlling the drying environment, you ensure your waterproofing works as intended and your gear is protected for seasons to come.

Summary Table:

| Drying Method | Why It Works | Key Consideration |

|---|---|---|

| Air Dry at Room Temperature | Allows waterproofing agents to cure and bond with fabric fibers. | Avoid direct heat sources like hairdryers or radiators. |

| Use a Fan for Airflow | Circulates air to safely speed up evaporation without damage. | Use low/medium speed; do not blast gear directly. |

| Newspaper for Boots/Gloves | Wicks moisture from the inside, preventing internal dampness. | Change newspaper every few hours when damp. |

Need to waterproof and dry gear in bulk? As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear and gear for distributors, brand owners, and bulk clients. Our expertise ensures your products are built to last and perform. Contact our team today to discuss your manufacturing needs and how we can deliver quality and value.

Visual Guide

Related Products

- Durable Spiked Camouflage Boots Wholesale & Factory Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Suede Chelsea Safety Boots for Custom & Private Label Manufacturing

People Also Ask

- How does the boot fitting process work for custom hunting boots? Achieve Perfect Fit for Backcountry Hunts

- What should you look for in waterproof hunting boots? The Ultimate Guide for Dry Feet in the Field

- Why might wearing multiple pairs of socks be counterproductive? Avoid This Common Cold-Weather Mistake

- Why is waterproofing important in hunting boots? Keep Your Feet Dry for a Successful Hunt

- What are the key takeaways when choosing hunting boots? Match Your Boots to the Terrain for Safety and Performance