To meet NFPA 1977 standards, a wildland firefighter boot must satisfy a comprehensive set of performance requirements covering heat, flame, puncture, and slip resistance. Key benchmarks include a minimum height of 8 inches to support the ankle, an internal sole temperature that cannot exceed 111°F during heat testing, and materials that will not melt or drip when exposed to flame. These criteria ensure the boot functions as a critical piece of protective equipment in extreme conditions.

NFPA 1977 is not just a checklist; it's a performance-based standard designed to ensure a boot provides a critical layer of protection against the thermal and physical hazards of wildland firefighting. Understanding these requirements moves you beyond the label to appreciating how each feature contributes to your safety and effectiveness on the fire line.

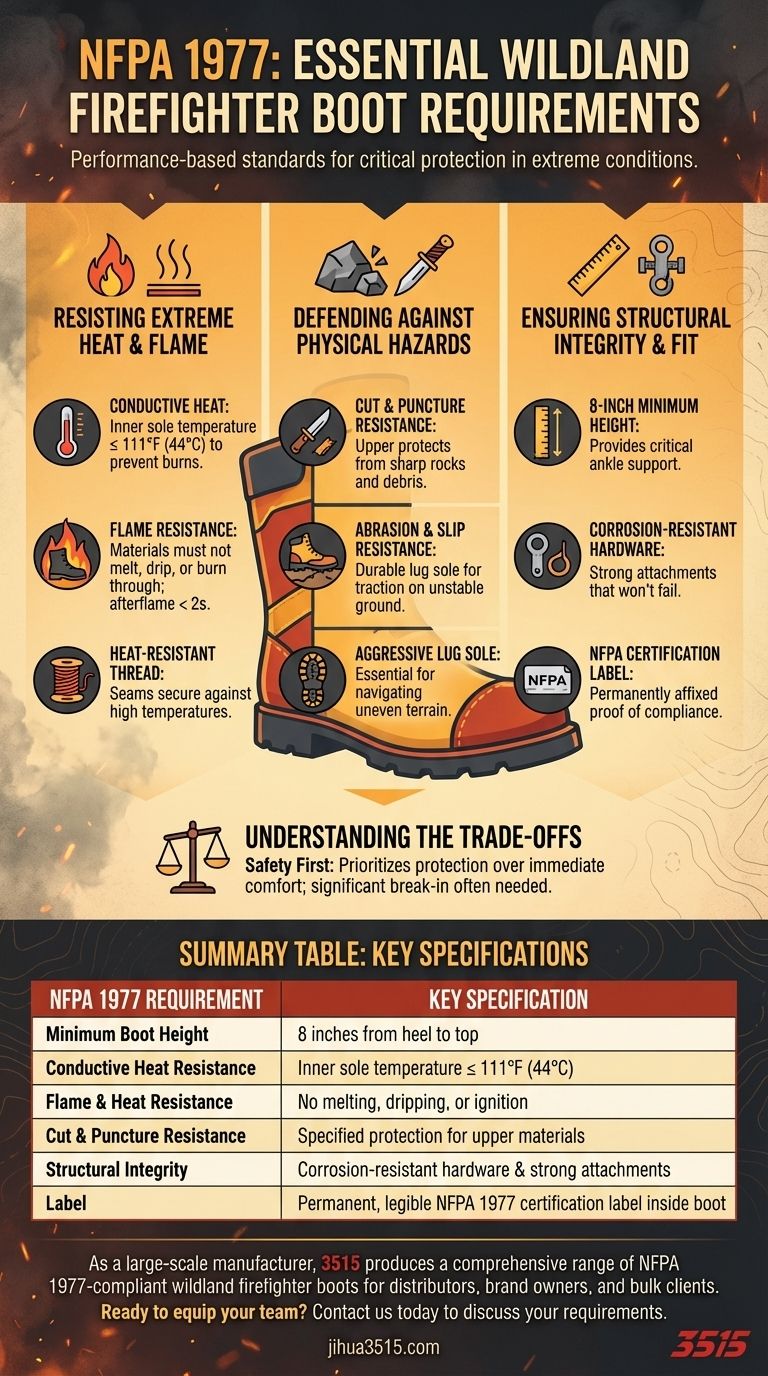

The Core Pillars of NFPA 1977 Protection

The NFPA 1977 standard is organized around three key principles: defending against extreme heat, protecting from physical hazards, and ensuring the boot's structural integrity under stress.

Resisting Extreme Heat and Flame

A firefighter's feet are in constant proximity to intense heat, both from the ground and surrounding flames. The standard addresses this with multiple, layered requirements.

Conductive Heat Resistance

This is one of the most critical thermal tests. The boot's sole is exposed to high heat, and the temperature on the inside surface of the sole cannot exceed 111°F (44°C). This prevents the ground itself from causing serious burns to the bottom of your feet.

Overall Heat Resistance

The entire boot is tested to ensure its materials do not melt, delaminate, or ignite when exposed to high ambient heat. This guarantees the boot maintains its shape and protective qualities when you are near the fire.

Flame Resistance

In a direct flame contact test, the boot materials must not melt, drip, or burn through. After the flame is removed, any lingering afterflame must extinguish in under two seconds, preventing the boot itself from becoming a fuel source.

Heat-Resistant Thread

All sewing thread used in the boot's construction must be inherently heat-resistant, like Technora or similar materials. This ensures the seams that hold the boot together do not fail when exposed to high temperatures.

Defending Against Physical Hazards

Wildland terrain is unforgiving. The standard mandates protection against the sharp, abrasive, and unstable surfaces you will encounter.

Cut and Puncture Resistance

The boot's upper, typically made of thick leather, must provide a specified level of resistance to cuts and punctures. This protects you from sharp rocks, branches, and debris on the fire line.

Abrasion and Slip Resistance

The outsole must be highly abrasion-resistant to withstand grinding wear from rock and grit. It must also provide proven slip resistance on various surfaces to ensure stable footing on steep or loose terrain.

The Lug Sole

Most compliant boots feature a deep, aggressive lug sole. This design is essential for providing the traction needed to navigate challenging and uneven ground safely.

Ensuring Structural Integrity and Fit

A boot is useless if it falls apart or fails to support you. These requirements ensure the boot is built to last and to protect you from injury.

8-Inch Minimum Height

The boot must measure at least 8 inches from the bottom of the heel to the top. This height is not arbitrary; it's the minimum required to provide essential ankle support and prevent sprains and injuries on rough terrain.

Corrosion-Resistant Hardware

All metal parts, such as eyelets and hooks, must be corrosion-resistant. This prevents them from failing due to rust and exposure to moisture and fire-retardant chemicals.

Hardware Attachment Strength

Eyelets and hooks must also pass a strength test to ensure they do not pull out or fail when laces are tightened under high tension, which is common during firefighting operations.

The NFPA Label

A compliant boot must have an interior label that is legible and permanently affixed. This is your proof that the manufacturer certifies the boot meets every requirement of the NFPA 1977 standard.

Understanding the Trade-offs

Meeting the NFPA standard requires specific design choices, and it's important to understand the implications.

Performance vs. Comfort

The materials required for NFPA compliance, like thick, vegetable-tanned leather, offer immense protection but often require a significant break-in period. The standard rightly prioritizes safety over out-of-the-box comfort.

A Minimum Standard, Not a Maximum

NFPA 1977 sets the minimum safety baseline. Manufacturers can, and often do, exceed these standards in areas like material quality or construction methods. Not all certified boots offer the same level of long-term durability.

What the Standard Doesn't Specify

The standard dictates performance, not specific comfort features. The quality of the insole, the boot's internal shape (last), and arch support are not defined. This leaves room for manufacturers to differentiate their products and for you to find a boot that matches your foot shape.

Making the Right Choice for Your Mission

Use the NFPA 1977 standard as your foundation, then consider your specific needs.

- If your primary focus is meeting agency requirements: Ensure any boot you consider has a clearly visible and permanently affixed NFPA 1977 label inside.

- If your primary focus is long-term durability: Look for features that exceed the standard, such as premium leather uppers and Goodyear welt or stitch-down construction for maximum structural integrity.

- If your primary focus is comfort on long assignments: Pay close attention to features not defined by the standard, such as the quality of the insole, the boot's shape, and reviews from other firefighters regarding the break-in period.

Ultimately, an NFPA 1977-compliant boot is your foundational tool for safety and performance in the unpredictable wildland environment.

Summary Table:

| NFPA 1977 Requirement | Key Specification |

|---|---|

| Minimum Boot Height | 8 inches from heel to top |

| Conductive Heat Resistance | Inner sole temperature ≤ 111°F (44°C) |

| Flame & Heat Resistance | No melting, dripping, or ignition |

| Cut & Puncture Resistance | Specified protection for upper materials |

| Structural Integrity | Corrosion-resistant hardware & strong attachments |

| Label | Permanent, legible NFPA 1977 certification label inside boot |

As a large-scale manufacturer, 3515 produces a comprehensive range of NFPA 1977-compliant wildland firefighter boots for distributors, brand owners, and bulk clients. Our production capabilities ensure every boot meets or exceeds the rigorous safety standards for heat, flame, and puncture resistance, providing the durability and protection you need in extreme conditions.

Ready to equip your team with reliable, certified footwear? Contact us today to discuss your specific requirements and learn how our expertise can support your mission.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Wholesale Lightweight Tactical Boots Custom Manufacturer for Desert & Combat Use

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What features should cowboy boots have for rugged, physical labor jobs? Essential Safety & Durability Guide

- What other workplace hazards are denoted on safety toe boots? Decode the EH, Mt, and SD markings.

- What are the disadvantages of pull on work boots? The Critical Fit & Safety Trade-Offs

- What challenges do women face when transitioning from men's to women's work boots? Achieve a Perfect, Anatomical Fit

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- What are the common construction methods for work boots? Choose the Right Build for Your Job

- What material is recommended for insole cushioning in boots? Poron vs. Leather Explained

- What are the key advantages of cowboy boots? Discover Unmatched Durability & Style