The primary types of protective safety toes are steel, alloy, and composite. While all three are engineered to meet the same foundational safety standards for impact, they are made from different materials that offer distinct advantages in weight, conductivity, and cost. A fourth common type, the soft toe, offers no impact protection and is meant for workplaces where such hazards are absent.

Choosing the right safety toe is not about finding the "strongest" option, as all certified caps meet the same impact standard. The crucial decision is matching the material's specific properties—like weight, thermal conductivity, and price—to the unique demands and hazards of your work environment.

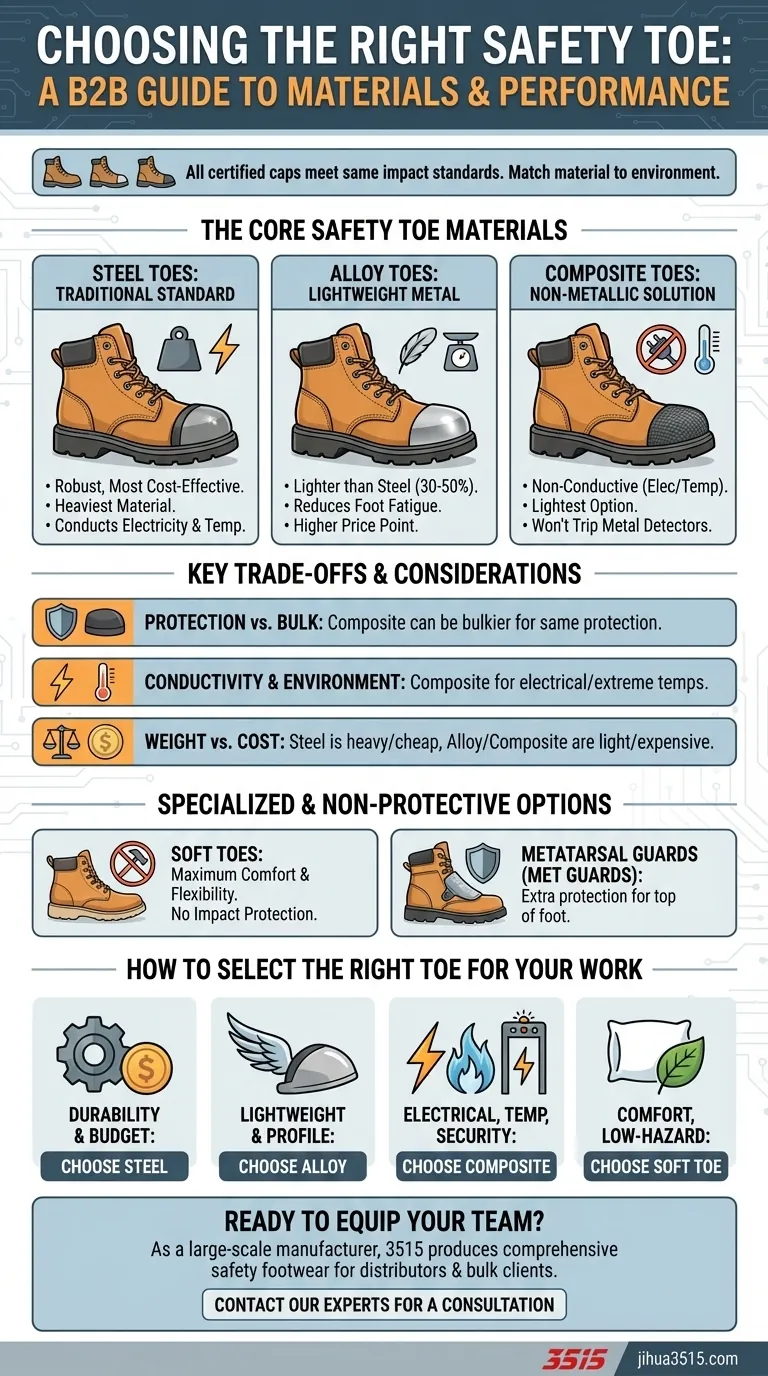

The Core Safety Toe Materials

To select the right footwear, you must first understand the fundamental differences between the three primary protective materials.

Steel Toes: The Traditional Standard

Steel is the original material for safety toes and remains a popular, heavy-duty choice.

It provides robust protection and is typically the most cost-effective option available.

However, steel is the heaviest material and will conduct electricity. It also readily transfers ambient heat and cold to your feet.

Alloy Toes: The Lightweight Metal

Alloy toes are crafted from modern, lightweight metals such as aluminum or titanium.

They offer the same certified protection as steel but are significantly lighter, often by 30-50%, which reduces foot fatigue over a long day.

This reduction in weight usually comes at a higher price point compared to traditional steel toes.

Composite Toes: The Non-Metallic Solution

Composite toes are made entirely from non-metal materials like carbon fiber, Kevlar, plastic, or fiberglass.

Their key advantage is that they do not conduct electricity, heat, or cold, making them ideal for electricians or those working in extreme temperatures.

They are the lightest protective option and will not set off metal detectors, a crucial feature for certain security-sensitive job sites.

Understanding the Key Trade-offs

Every safety toe represents a balance of features. Understanding these trade-offs is essential for making an informed decision.

Protection Level vs. Material Bulk

All certified safety toes must meet the same ASTM standard for impact and compression resistance. They are all equally "safe" from a standards perspective.

The difference lies in material density. A steel cap can be thinner than a composite cap while providing the same level of protection, which can affect the boot's profile.

Conductivity and Environment

Your work environment is the most critical factor. If you work around live electrical currents, a non-metallic composite toe is essential for safety.

In very hot or cold conditions, steel and alloy toes will transfer that temperature, while composite toes provide a valuable layer of insulation.

Weight vs. Cost

There is almost always a direct trade-off between the material's weight and its cost.

Steel is the heaviest but most budget-friendly. Alloy and composite toes offer significant weight reduction but typically increase the overall price of the footwear.

Specialized and Non-Protective Options

Beyond the big three, two other terms are important to know.

Soft Toes

A "soft toe" boot has no protective toe cap whatsoever.

It is designed purely for comfort and flexibility in job roles where there is no risk of falling objects or foot compression injuries.

Metatarsal Guards (Met Guards)

This is a separate feature that provides protection beyond just the toe cap.

Met guards are internal or external shields that protect the delicate metatarsal bones on the top of your foot from impact, a hazard common in heavy industrial or construction work.

How to Select the Right Toe for Your Work

Consider your specific job hazards, environmental conditions, and daily physical demands to make the right choice.

- If your primary focus is maximum durability on a budget: Choose steel toe boots for their proven strength and cost-effectiveness in demanding environments.

- If your primary focus is lightweight protection and a lower-profile cap: Select alloy toes to reduce foot fatigue without sacrificing the benefits of a metal toe.

- If your primary focus is working around electricity, in extreme temperatures, or passing through metal detectors: Composite toes are the ideal choice for their non-conductive, insulating, and lightweight properties.

- If your primary focus is all-day comfort in a low-hazard environment: A soft toe provides the most flexibility when impact protection is not a job requirement.

Equipping yourself with the right safety toe transforms your footwear from a simple requirement into a specialized tool for your performance and safety.

Summary Table:

| Safety Toe Type | Material | Key Advantages | Key Disadvantages | Best For |

|---|---|---|---|---|

| Steel Toe | Steel | Cost-effective, durable, proven protection | Heaviest, conducts electricity & temperature | Demanding industrial work on a budget |

| Alloy Toe | Aluminum/Titanium | Lighter than steel (30-50%), lower profile | Higher cost than steel | Reducing foot fatigue without sacrificing metal protection |

| Composite Toe | Carbon Fiber/Plastic | Lightest, non-conductive, insulates from temperature | Can be bulkier than metal for same protection | Electricians, extreme temperatures, security-sensitive sites |

| Soft Toe | N/A (No cap) | Maximum comfort and flexibility | No impact protection | Low-hazard environments where safety toes are not required |

Ready to Equip Your Team with the Right Safety Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and shoes, ensuring you get the perfect fit of protection, comfort, and value for your specific workforce needs.

Let us help you make the right choice. Contact our experts today for a consultation and see how we can support your business.

Visual Guide

Related Products

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- How do safety boots reduce cutting hazards? Essential Protection for Your Workforce

- What does the impact rating in safety toe boots mean? Choose the Right Protection for Your Job

- What are the common types of safety boots and their primary uses? A Guide to Industrial Footwear

- How does the design of specialized work shoes and safety boots facilitate the effective use of PPE? Streamline Your Safety

- Why is it important to prioritize safety and comfort in work footwear? Boost Performance & Prevent Injury

- What role do IoT cloud application platforms play in diabetic foot monitoring? Enhancing Real-Time Patient Prevention

- What industries commonly require protective footwear? Essential Foot Safety for High-Risk Sectors

- What is the primary function of protective footwear in poultry biosecurity? Maximize Flock Health and Biosecurity