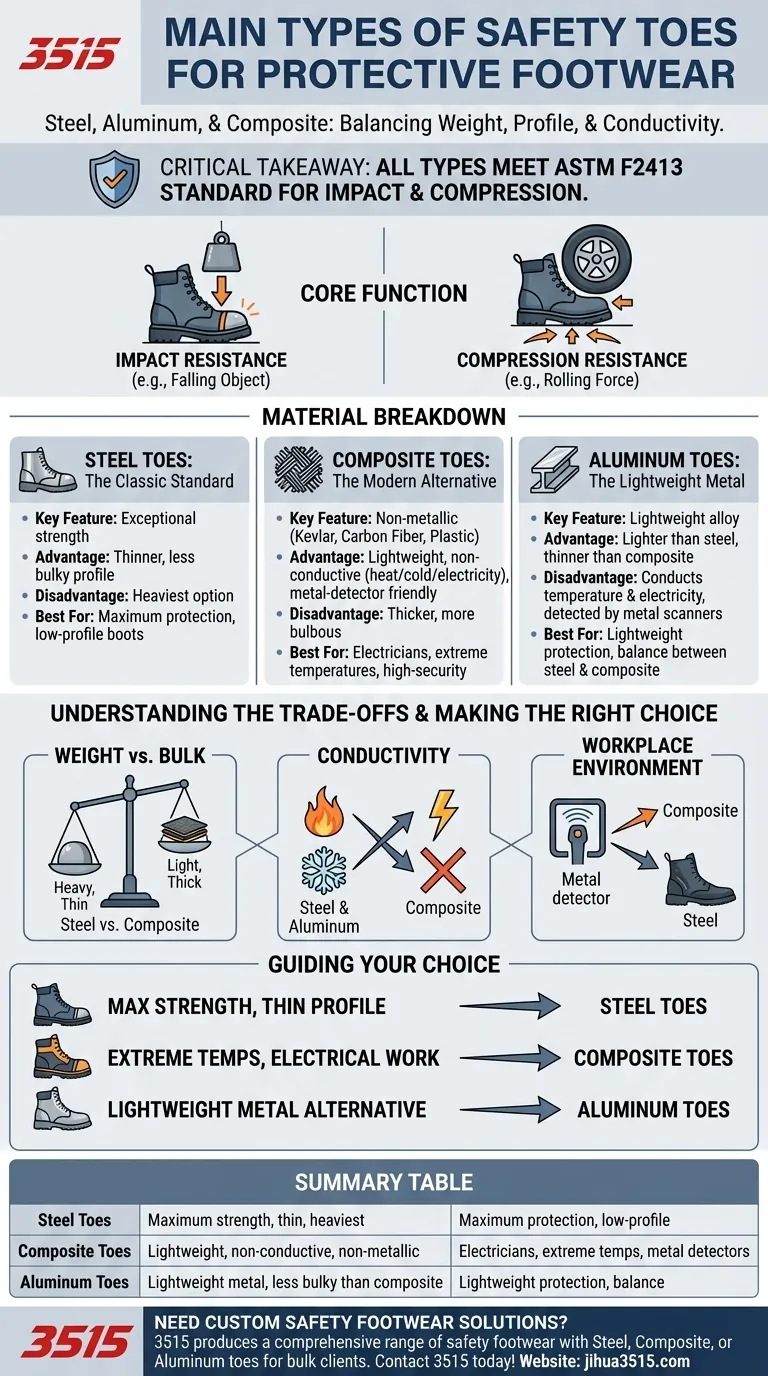

At their core, the main types of safety toes for protective footwear are steel, aluminum, and composite. Each material offers a different balance of weight, profile, and conductivity, allowing you to choose the best option for your specific work environment and personal comfort.

The most critical takeaway is that all safety toes—regardless of material—must meet the same rigorous ASTM F2413 safety standard for impact and compression. The choice between them is not about which is "safer" in a direct impact, but about which best fits the unique demands of your job and body.

The Core Function: Protecting Against Impact and Compression

Before comparing materials, it's essential to understand their shared purpose. A safety toe's job is to protect your feet from two primary types of hazards.

Impact Resistance

This refers to protection from a heavy object falling directly onto the toe of your boot. The standardized test measures the toe cap's ability to withstand a specific amount of force (e.g., 200 Joules) from a dropped weight.

Compression Resistance

This refers to protection from a rolling or crushing force, like a vehicle or cart running over your foot. The test measures the cap's ability to resist a static load (e.g., 15 kN) without deforming.

Material Breakdown: Steel, Composite, and Aluminum

While all certified safety toes pass the same fundamental tests, the material used to construct them creates distinct advantages and disadvantages in daily use.

Steel Toes: The Classic Standard

Steel is the traditional material for safety toes, known for its exceptional strength.

Because of its strength, a steel toe cap can be made thinner than a composite cap while still meeting ASTM standards. This results in a less bulky, lower-profile boot. However, steel is the heaviest of the three options.

Composite Toes: The Modern Alternative

Composite toes are made from non-metallic materials like Kevlar, carbon fiber, or plastic.

Their key advantage is being lightweight and non-conductive. They do not transfer heat or cold and will not set off metal detectors, making them ideal for electricians or workers in high-security environments. The trade-off is that they are thicker and more bulbous than steel toes to achieve the same strength rating.

Aluminum Toes: The Lightweight Metal

Aluminum (and other light alloys) offers a middle ground between steel and composite.

It is significantly lighter than steel while remaining thinner and less bulky than composite. Like steel, it is a metal and will conduct temperature and be detected by metal scanners.

Understanding the Trade-offs

Choosing the right safety toe involves balancing competing factors. There is no single "best" material, only the best material for a specific application.

Weight vs. Bulk

Heavier materials like steel allow for a thinner, less bulky toe cap. Lighter materials like composite require more mass, resulting in a thicker, more prominent toe box.

Thermal and Electrical Conductivity

Metal toes (steel and aluminum) will conduct heat, cold, and electricity. This can be a major comfort issue in extreme temperatures and a safety hazard for those working with live electrical circuits.

Workplace Environment

Consider your daily tasks. If you frequently pass through metal detectors, a composite toe will save significant time and hassle. If you prioritize a sleek, low-profile boot, steel is often the best choice.

Making the Right Choice for Your Goal

Your final decision should be guided by a clear understanding of your work environment's hazards and your personal comfort needs.

- If your primary focus is maximum strength in the thinnest profile: Choose steel toes, which offer robust protection without adding excessive bulk to the boot's appearance.

- If your primary focus is working in extreme temperatures or around electricity: Choose composite toes, as their non-metallic nature prevents thermal and electrical conductivity.

- If your primary focus is finding a lightweight metal alternative: Choose aluminum toes for a balance of protection that is lighter than steel and less bulky than composite.

Ultimately, selecting the right safety toe is a crucial step in ensuring both your safety and your comfort throughout the workday.

Summary Table:

| Material | Key Features | Best For |

|---|---|---|

| Steel Toes | Maximum strength, thin profile, heaviest | Maximum protection, low-profile boots |

| Composite Toes | Lightweight, non-conductive, non-metallic | Electricians, extreme temperatures, metal detectors |

| Aluminum Toes | Lightweight metal, less bulky than composite | Lightweight protection, a balance between steel and composite |

Need Custom Safety Footwear Solutions?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots with steel, composite, or aluminum safety toes, ensuring your team gets the perfect blend of protection and comfort.

Contact 3515 today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- How does a dual-belt medical treadmill contribute to the gait analysis of safety footwear? Precision Kinetic Testing

- Why are industrial-grade safety shoes essential for metal stamping? Prevent Injuries with Advanced Protection

- What critical protection do industrial-grade safety shoes provide in furniture manufacturing? Ensure Total Foot Safety

- Why might healthcare professionals need safety shoes? Essential Protection for Hospital Hazards

- What role does protective footwear play in the comprehensive safety protocol for a natural stone production line? Essential Multi-Hazard Protection & Operational Continuity

- How do safety shoes and puncture-resistant boots protect against snakebites? Secure Your Field Workers with 3515 Gear

- Why must differences between Russian GOST 11373 and European safety shoe standards be considered? Ensure Precision Fit.

- What additional consideration is mentioned if protective footwear is electric shock resistant? Employer's Financial Responsibility