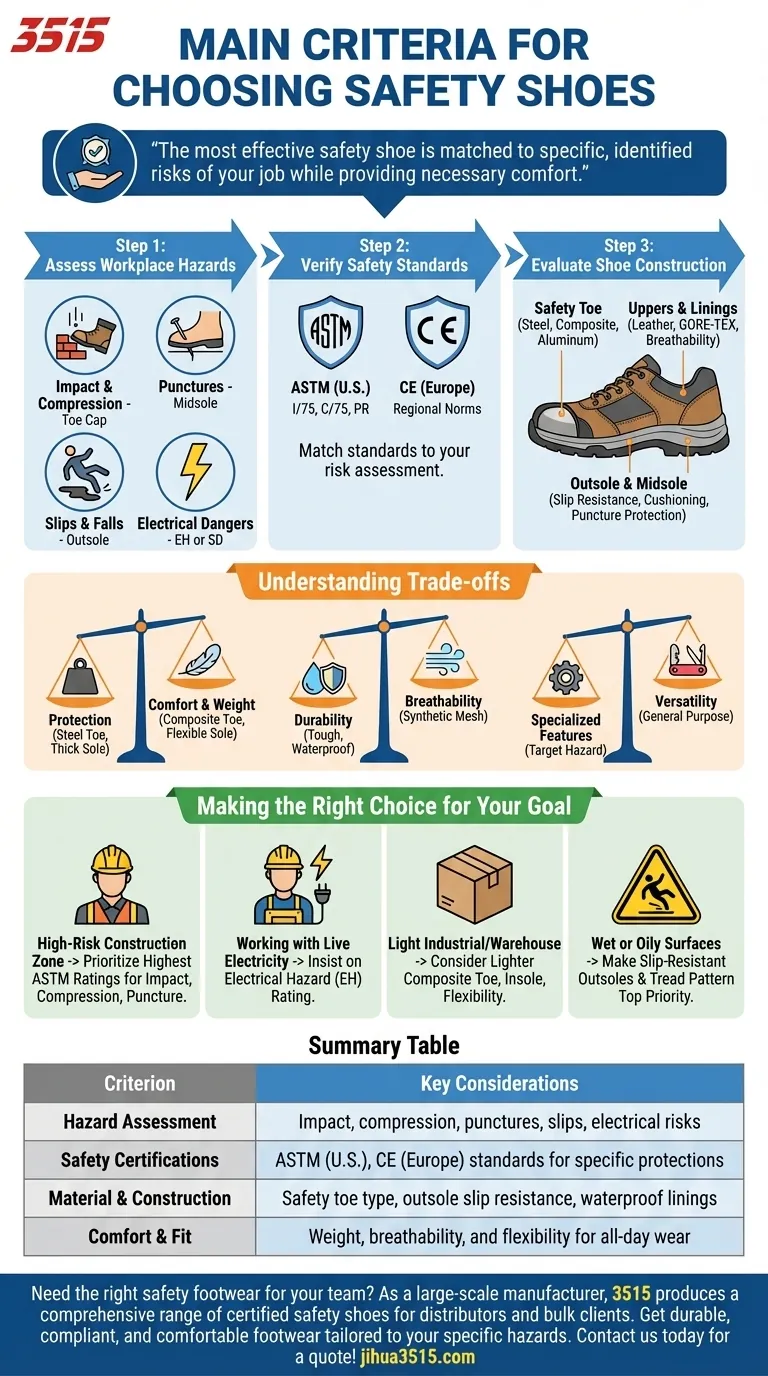

In choosing safety shoes, the primary criteria are the specific hazards of your workplace, the required safety certifications like ASTM or CE, and the shoe's material and construction for both protection and comfort. You must first identify the risks you face—such as impact, compression, punctures, or electrical hazards—and then select a shoe certified to protect against them.

The most effective safety shoe is not the one with the most features, but the one correctly matched to the specific, identified risks of your job while providing the necessary comfort for daily wear.

Breaking Down Your Safety Footwear Needs

Choosing the right safety shoe is a systematic process of matching footwear features to your work environment. It goes beyond simply picking a steel-toed boot. A thorough assessment ensures protection, compliance, and all-day comfort.

Step 1: Assess Your Workplace Hazards

The single most important step is to analyze the specific risks present in your work environment. A shoe designed for a warehouse is ill-suited for an electrician.

Impact and Compression This is the most fundamental feature, protecting your toes from falling objects or crushing forces. The safety toe cap is the key component here.

Punctures If you work around nails, scrap metal, or other sharp objects on the ground, a puncture-resistant midsole is non-negotiable.

Slips and Falls Consider your typical floor surfaces. Do you work on wet, oily, or uneven terrain? A slip-resistant outsole is critical for maintaining traction and preventing falls.

Electrical Dangers Your needs vary drastically based on the electrical risk. Electrical Hazard (EH) rated shoes protect you from shock, while static dissipative (SD) shoes prevent the buildup of static electricity.

Step 2: Verify Safety Standards and Compliance

Professional safety footwear is not just "strong"—it's certified to meet specific performance standards.

Check for Certifications In the United States, look for compliance with ASTM (American Society for Testing and Materials) standards. In Europe, the CE marking is required, signifying it meets regional safety and quality norms.

Match Standards to Your Risks These certifications are not one-size-fits-all. An ASTM-rated shoe will have specific codes indicating what it protects against (e.g., I/75 for impact, C/75 for compression, PR for puncture resistance). Ensure the shoe's rating matches your hazard assessment.

Step 3: Evaluate Shoe Construction and Materials

The components of the shoe work together to provide protection and comfort. Understanding them helps you make a more informed choice.

The Safety Toe This is the reinforced area protecting your toes. It's often made of steel, but lighter alternatives like composite materials or aluminum are common and offer similar protection with less weight and better insulation.

Outsole and Midsole The outsole is the part that contacts the ground, critical for slip resistance. The midsole provides cushioning and, in many cases, puncture protection.

Uppers and Linings The upper material (e.g., leather, synthetic fabric) determines durability and breathability. Linings, like a GORE-TEX waterproof liner, can provide crucial protection from the elements.

Understanding the Trade-offs

There is no single "best" safety shoe, only the best one for your specific context. Every choice involves a trade-off between different features.

Protection vs. Comfort and Weight

Heavily reinforced shoes with steel toes and thick soles offer maximum protection but can be heavy and fatiguing. Lighter composite toes and flexible soles may increase comfort but might not be suitable for the most extreme-risk environments.

Durability vs. Breathability

Tough, waterproof materials like thick leather offer excellent durability and protection from liquids. However, they are often less breathable than synthetic mesh uppers, which can be a critical factor in hot climates.

Specialized Features vs. Versatility

A highly specialized shoe—for example, one designed for a foundry—offers incredible protection against its target hazard but may be cumbersome and uncomfortable for general-purpose use. Over-investing in features you don't need can compromise daily comfort.

Making the Right Choice for Your Goal

Your final decision should be guided by a clear understanding of your priorities.

- If your primary focus is compliance in a high-risk construction zone: Prioritize shoes with the highest ASTM ratings for impact, compression, and puncture resistance.

- If your primary focus is working with live electricity: Insist on an Electrical Hazard (EH) rating to ensure protection from open circuits.

- If your primary focus is all-day comfort in a light industrial or warehouse setting: Consider a lighter composite toe and evaluate the shoe's insole and overall flexibility.

- If your primary focus is preventing falls on wet or oily surfaces: Make slip-resistant outsoles your top priority and check the tread pattern.

Ultimately, the right safety shoe is a critical piece of personal protective equipment that directly supports your safety and well-being at work.

Summary Table:

| Criterion | Key Considerations |

|---|---|

| Hazard Assessment | Impact, compression, punctures, slips, electrical risks |

| Safety Certifications | ASTM (U.S.), CE (Europe) standards for specific protections |

| Material & Construction | Safety toe type (steel/composite), outsole slip resistance, waterproof linings |

| Comfort & Fit | Weight, breathability, and flexibility for all-day wear |

Need the right safety footwear for your team? As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety shoes and boots for distributors, brand owners, and bulk clients. Our expertise ensures you get durable, compliant, and comfortable footwear tailored to your specific workplace hazards. Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- Why is moisture management a critical design feature for safety boots? Boost Mining Safety and Worker Skin Health.

- What materials are commonly used in the manufacture of safety shoes? A Guide to Leather, Steel & Composite Components

- What are the key ASTM standards for protective footwear compliance? Ensure Workplace Safety & OSHA Compliance

- What are the characteristics of suede leather used in labour protection shoes? A Guide to Comfort vs. Durability

- What are the key features to look for in work shoes? Find the Perfect Balance of Safety & Comfort

- Why compare professional safety shoes vs slippers for plantar fascia? The Science of Occupational Foot Strain Prevention

- What are the advantages of composite-toed shoes? Lighter, Safer, and More Comfortable

- What are best practices for maintaining safety shoes? Extend Lifespan & Ensure Protection