At its core, Polyvinyl Chloride (PVC) is a cornerstone of modern manufacturing, prized for its use in applications ranging from rigid construction materials like pipes and window frames to flexible goods such as electrical cable insulation and medical tubing. Its widespread adoption stems from its unique ability to be formulated into two primary forms—rigid and flexible—making it one of the most versatile and cost-effective polymers available.

The true value of PVC lies not in a single application, but in its chemical adaptability. By choosing between its rigid or flexible state, manufacturers can leverage a single polymer for an enormous spectrum of products, from structural building components to pliable consumer goods.

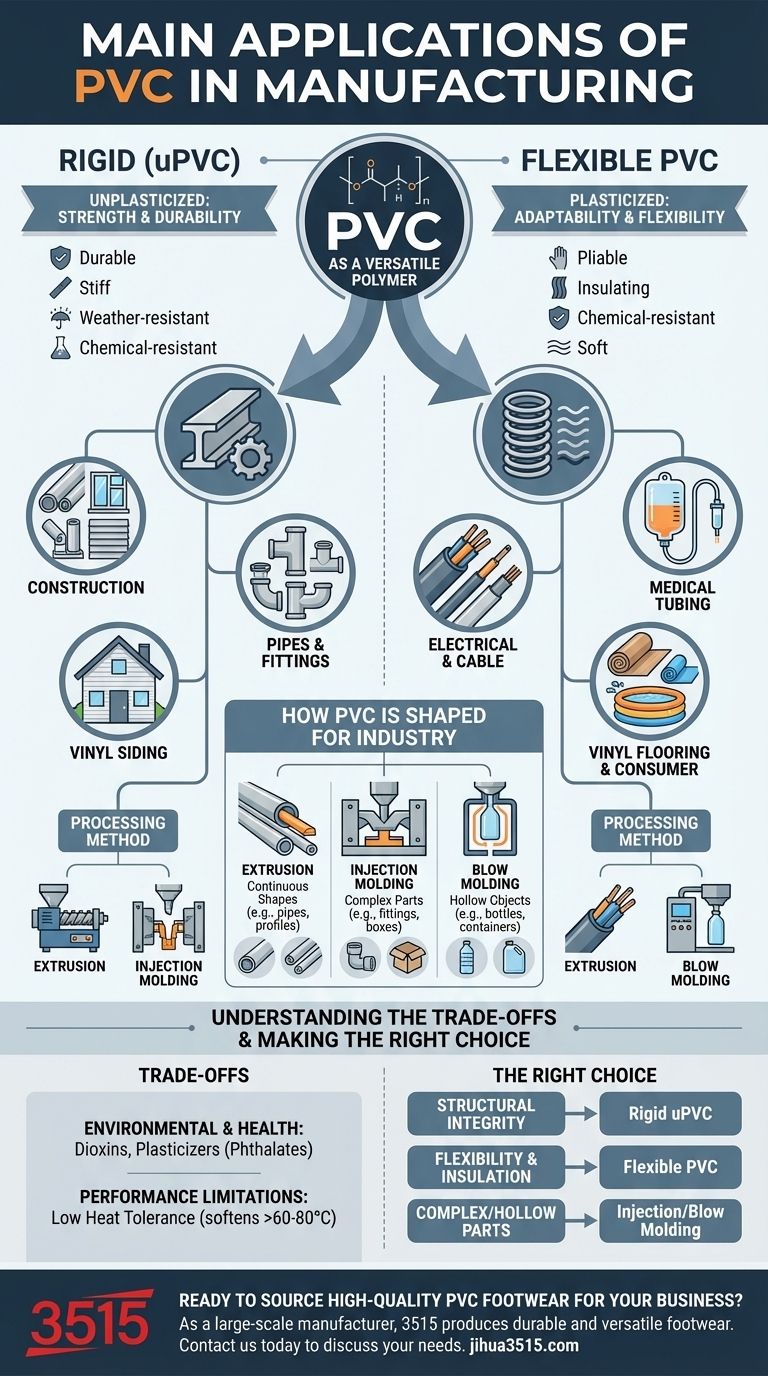

The Two Faces of PVC: Rigid vs. Flexible

The fundamental distinction driving PVC's applications is whether it is plasticized. This single factor determines if the end product will be hard and structural or soft and compliant.

Rigid PVC (uPVC): The Power of Strength

Unplasticized PVC, often called uPVC or rigid PVC, is known for its exceptional durability, stiffness, and resistance to chemicals and weathering.

These properties make it the material of choice for the construction industry. Common applications include water and sewer pipes, window and door frames, and vinyl siding.

Its resistance to corrosion and low cost give it a significant advantage over traditional materials like metal and wood in these long-term, structural roles.

Flexible PVC: Engineered for Adaptability

By adding chemical plasticizers, rigid PVC is transformed into a soft, pliable material. This flexibility unlocks an entirely different set of applications.

It is widely used for electrical cable insulation and sheathing, where its dielectric properties and durability are critical for safety and performance.

Other key uses include vinyl flooring, medical-grade tubing and blood bags, inflatable products like pool liners, and protective clothing.

How PVC is Shaped for Industry

The form of PVC dictates not only its properties but also how it is processed. Manufacturers select a method based on the desired shape and volume of the final product.

Extrusion for Continuous Shapes

Extrusion is the dominant process for producing long, continuous profiles. This method is ideal for creating pipes, window frames, siding, and wire insulation.

Heated PVC is forced through a shaped die, resulting in a consistent cross-section that can be cut to any length.

Injection Molding for Complex Parts

When creating complex, three-dimensional objects, manufacturers turn to injection molding. This process is used for items like pipe fittings, electrical boxes, and automotive parts.

Melted PVC is injected under high pressure into a custom mold, allowing for intricate designs and high-volume, repeatable production.

Blow Molding for Hollow Objects

Blow molding is a specialized process used to create hollow items. It is commonly used for manufacturing bottles and containers, particularly for chemicals or household products where PVC's chemical resistance is an advantage.

Understanding the Trade-offs

While incredibly versatile, PVC is not without its challenges. An objective assessment requires acknowledging its limitations.

Environmental and Health Considerations

The production and disposal of PVC can be controversial. Its chlorine content can create toxic dioxins if incinerated improperly.

Additionally, certain plasticizers (like some phthalates) used to make PVC flexible have faced scrutiny for potential health risks, leading to regulations and the development of alternative formulations.

Performance Limitations

Standard PVC has a relatively low heat tolerance compared to other engineering plastics. It can begin to soften and lose its structural integrity at temperatures above 60-80°C (140-176°F).

This makes it unsuitable for high-temperature applications where materials like CPVC (Chlorinated PVC) or other polymers would be required.

Making the Right Choice for Your Application

Selecting the correct type of PVC is essential for project success. Your decision should be guided by the primary requirement of the end product.

- If your primary focus is structural integrity and outdoor durability: Rigid uPVC is the definitive choice for applications like pipes, window profiles, and siding.

- If your primary focus is flexibility and insulation: Plasticized PVC is the ideal material for electrical cables, resilient flooring, and medical tubing.

- If your primary focus is cost-effective production of complex or hollow parts: PVC's excellent processability through injection and blow molding makes it a leading candidate.

Understanding PVC's dual nature is the key to unlocking its vast manufacturing potential for your specific goal.

Summary Table:

| PVC Type | Key Properties | Common Applications |

|---|---|---|

| Rigid (uPVC) | Durable, Stiff, Weather-resistant | Pipes, Window Frames, Siding |

| Flexible | Pliable, Insulating, Chemical-resistant | Cable Insulation, Medical Tubing, Flooring |

| Processing Method | Ideal For | Example Products |

| Extrusion | Continuous Profiles | Pipes, Window Frames, Wire Insulation |

| Injection Molding | Complex 3D Parts | Pipe Fittings, Electrical Boxes |

| Blow Molding | Hollow Objects | Bottles, Containers |

Ready to source high-quality PVC footwear for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and versatile footwear for distributors, brand owners, and bulk clients. Our expertise in polymer processing ensures reliable performance for industrial, safety, and consumer applications.

Contact us today to discuss your specific needs and leverage our production capabilities for your next project.

Visual Guide

Related Products

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Wholesale Durable Camo Canvas Shoes with High-Traction Rubber Soles

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

People Also Ask

- How does a biomechanical digital tracking system assist in reducing bone strain risks? Prevent Tactical Training Injuries

- What are the key functions of 3D modeling and simulation software? Modernizing Apparel & Footwear Design

- How do shoes impact indoor air quality? Uncover the Hidden Toxins in Your Home

- What are the traditional and contemporary options for dressage boots? Choose the Perfect Boot for Your Riding Style

- How does a firm support chassis contribute to footwear for sensory impairments? Stability Meets Sensory Regulation

- What is the purpose of designing experimental footwear with varying HTD gradients? Optimize Gait Stability & Safety

- What are snip toe cowboy boots best suited for? A Guide to Fashion vs. Function

- How is Cordura used in footwear? Achieve Lightweight, Maximum Durability